Is it possible to lay a rabbeted moisture resistant chipboard on the floor?

During interior work it is often necessary to level the surfaces - the floor, the walls or the ceiling. Many building materials used for this purpose, rather whimsical in storage, unstable to moisture and elevated temperatures. Without a special protective coating, they quickly lose their presentation and need to be replaced. And their installation is very time consuming due to the inconvenience and the need to attract a team of specialists.

That is why to solve this problem, experienced craftsmen use tongueled chipboard because of its persistent qualities and easy installation. The material is resistant to temperature and moisture, and thanks to the special grooves at the edges, the plates easily fit together. The main thing is to install and fix it in the presence of all the necessary tools can even be alone.

Special features

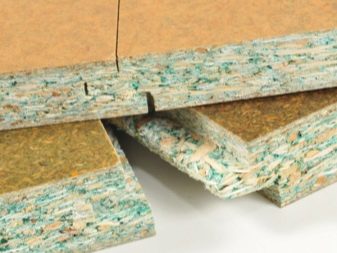

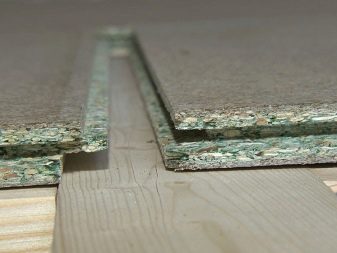

Grooved chipboard - a common building material, presented in the form of panels having protrusions on the edges on one side, and gutters on the other.The depth of the grooves (grooves) corresponds to the height of the protrusions, ensuring the tight joining of the sheets among themselves. In production, the mass of sawdust is compacted under a press with the addition of special resins, ensuring the water resistance of the material. Therefore, as shown by the tests, a particle board completely immersed in liquid for a day can increase from swelling by only 10%.

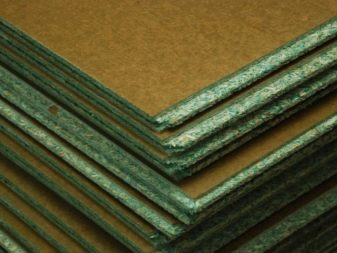

Past pressing at elevated temperature, the plates have high strength and therefore are often used for roughing the flooring. Noticeable persistent qualities endowed with special laminated chipboard.

When it is manufactured, products of the first grade (without noticeable defects) are applied with a special film coating, increasing the wear resistance of the material.

Advantages and disadvantages

The positive qualities of this material include:

- The high density of the plates is characterized by durability and rigidity of the coating, especially if the sheets are laid on logs.

- The chipboard structure evenly distributes the load over the entire floor area.

- Manufacturing technology allows you to eliminate dents and protrusions, observing the perfect flatness of the layers.

- Easy to install and remove as individual elements, and the entire structure due to the presence of grooves for tight joining and small dimensions of the plate.

- Immune to changes in temperature and humidity, harsh climatic conditions, as well as all kinds of mold and insects.

- Heat capacity and sound insulation.

- When complying with SanPiN standards, such chipboard can be used for finishing in kindergartens and hospitals due to the environmental friendliness of raw materials.

- Affordable, compared with similar building materials, the price. Reusable used b \ y plates.

As for the shortcomings of this choice, here it should be highlighted:

- Unattractive appearance, weakly possesses aesthetic features, does not look like a wooden finish at all, therefore it is better to use material for rough alignment of walls or floor, and you should already line decorative parquet over it.

- Resins added to chips during production may contain toxic substances that evaporate at room temperature. Therefore, before the acquisition, it is desirable to familiarize yourself with the composition and recommendation for use - is it allowed to use for the manufacture of furniture and in residential buildings.

- With a small resin content, additional insulation will be required, preserving the particle board from environmental factors.

- Not suitable for wavy or convex surfaces.

- Greater weight compared to wood paneling.

These shortcomings should be taken into account before buying building materials.

Where does it apply?

Specialists of finishing works recommend to install a rabbeted chipboard for rough alignment of walls. On this basis, a decorative coating is already applied: lining, board, laminate and so on. Also suitable for interior partitions.

Not bad plates perform the function of a suspended ceiling. Unlike drywall, they do not bend, are easy to install and weigh significantly less. Regarding the alignment of the floor - here chipboard has a special role. Pre-leveling promotes isolation from moisture and noise, which soothes the neighbors from the bottom. Linoleum or parquet is already applied to the surface of the sheets.

How to choose?

For fine finishing, builders are advised to choose a 3- and 5-layer flooring. Among the indicators of quality sheets emit resistance to stretching (0.2-0.6MPa). Also, the plate must withstand fracture under pressure up to 25 MPa.The permissible degree of swelling should not exceed 25%.

By strength and water-repellent property, the plate is marked with two classes:

- Class A - slightly swells with water. Suitable for use in rooms with high humidity.

- Class B - less resistant to moisture, so it is advisable to use only in dry rooms.

When buying you need to understand that the product of the first grade should not be present cracks and irregularities. Such layers can be used to level the floor.

The content of toxic formaldehyde in the resin in the manufacture of chipboard should be specified by the manufacturer on a prescriptive document — label, package, and so on.

- E1 indicates about 10 mg of formaldehyde in 100 grams of dry material.

- E2 - no more than 30 mg.

- E3 - has no more than 60 mg of harmful substances per 100 g of wood.

Sheets with a high content of resin used for exterior decoration or well-ventilated and technical premises - warehouses, utility rooms and others.

How does it work?

DSP differ in the number of layers of wood chips: single, three and multi-layered. For flooring, it is better to choose multilayer sheets that have large particles of wood inside, and smaller ones along the periphery. This will provide the necessary cushioning when walking.Also, the surface of the panels can be flame retardant, giving them heat resistance.

Installation of the subfloor

The roughing screed is the basis for further fixing the floor covering. Grooved water-resistant chipboard is easy to install yourself, without attracting expensive professionals. To do this, just follow the sequence of actions described below.

First, logs from a timber are mounted on a concrete screed, the distance between which is determined by the thickness of the slabs. With a sheet thickness of 16 mm, the bars must be laid at a distance of 30-40 cm, and with a thickness of 22 mm - up to 60 cm. The floor level is indicated on the wall with a pencil. Dredging and hollows in the concrete will have to fill with sand. Along the perimeter near the walls should definitely leave a small gap of 20 mm. If necessary, further insulate the floor. A layer of waterproofing is lined on the concrete under the bars, and foam or glass wool is laid between the bars.

Previously, all the electric wires, protected by a corrugated sheath, are placed in specially prepared gutters. It is recommended to treat the space with substances that kill insects so that colonies of parasites do not get divorced under the floor.

Before fixing plates indicated a place for the hatch, which opens access to electrical engineering.

The correctness of the installation lag is determined by the building level, and if everything is in order, special paper spreads on the frame on top to prevent creaking when walking. On the panels is marked and cut a hole for the hatch.

After that you can put chipboard. Cover start from the opposite side of the room. The laid panel is fixed with self-tapping screws, the first of which is screwed into the center, and the rest of them along the edges in order to ensure uniform laying of the coating. The cap of the screw should not protrude above the surface, therefore it is desirable to drown it by at least 1 mm. The area of one sheet should cover at least three lags in order not to lose rigidity and not bend.

To grooves and protrusions tightly interconnected, the masters recommend to process them with building glue or mastic.

With the first sheet, the second, third, and so on until the end. Plates are recommended to be positioned so that the joints between them pass over the bars. If you plan to cover the floor in a narrow corridor, then the ribs should be located across the track.

The irregularities arising during the installation are ground and then linoleum can be laid.

On concrete floor

Concrete is primed for maximum leveling of the surface. To ensure the evenness of the screed casting occurs using a level and special metal landmarks. The plaster mix is poured from the far corner so that there are no impurities and bubbles in the solution.

Above, dried gypsum is covered with insulation and covered with expanded clay. Then the plates, moistened with antiseptic, are laid one after another at a distance of about 2 cm from the wall. Installation, like pouring, starts from the opposite edge of the room.

Floating floor

This design is best suited for uneven wavy base. As in the variant above, waterproofing is lined on the concrete screed, and if it is a wooden floor, asphalt is straightened. Above, there is a spread of expanded clay, the upper layer of which is leveled and compacted. When the embankment does not have waves and depressions - the paper is laid, which is used so that the floor does not creak. As in the previous description, the installation of chipboard starts from the far corner, but before that, wedges are driven in near the walls so that there is a gap of 10 mm between them and the floor.

On the ceiling and walls

Sheets are fastened to the wall with screws by a distance of 30-40 cm from each other. When using nails, they are driven in at a 45 degree angle horizontally. The application of additional primer mesh is not required.

For the ceiling, choose panels with a thickness of 12 mm. As for drywall, the ceiling is equipped with a wooden frame, on which the chipboard is fastened with nails or screws. Further, all the necessary wiring is passed and the insulation is lined, and then the material can be fixed. It is also desirable to glue the seams here with a sealant or mastic.

Grooved moisture-resistant chipboard are notable for their durability and long service life, which has earned the recognition of many masters when working with flooring. Pre-leveled slabs can be covered with all types of flooring materials: linoleum, parquet, tile, laminate and others. The feedback given is mostly positive.

The versatility of the use of plates and their dimensions allows you to observe the most even covering of the walls, ceiling and floor, as well as interior partitions and dampers. Resistance to environmental factors, moisture and temperature changes, combined with ease of installation, makes this product very popular among the masters of interior decoration.In addition, it is unpretentious in storage, lightweight and has a low cost, compared with counterparts from other materials.

You will learn more about whether you can lay a rabbeted moisture-resistant chipboard on the floor from the following video.