Putty: types and their features

A putty is a finishing or building material of plastic type. As a rule, it is used as a base for the facing layer. This is the perfect way to level any surface. In addition, this coating is used for decoration. Therefore, it is important to study the features of all types of putty before buying a mixture.

Special features

Putty or putty - versatile material. It is always used in construction and repair. At the same time, disputes often arise as to how to correctly say: “putty” or “putty”. The fact is that now both of these words are used in the same meaning. Some believe that this word comes from the name of the tool - a spatula, since it is they who are given this building compound on the surface.

But there is still the word "to foul" - that is, to fill the gaps during construction with the help of tow. It is for these purposes and apply the putty. Therefore, we can assume that the name comes from this word. In any case, all these words belong to the same scope of application, and therefore are considered correct.

Someone says that the difference between these two concepts is colossal. So, they indicate that the putty is a mixture of a dry type of natural composition, and the putty is a synthetic mixture, which is presented in a ready-made form. But how this classification appeared is unclear. That is why many experts argue that these are words that have the same meaning, and both uses are valid.

Putty is applied with a special tool, from which she received, in the opinion of many, this name. So, the spackling tool looks like a plastering tool, but the spatula has a thinner blade and bends a little if you press its handle. Thus, the putty can be applied even a very thin layer, as well as control the uniformity. The application of the composition of this tool involves a certain pressure and tilt to properly distribute the composition of the surfaces.

The spatula blade is always smooth and perfectly smooth. There are always a number of requirements. For the correct application of putty spatula cut with a laser. So the blade becomes perfectly smooth. Even small roughness on the spatula can lead to incorrect and uneven application of putty. Together with the filler also used grinders in the form of an abrasive mesh or jointer bar.

The filler is a dispersion solution, but the filler is in it a very small fraction of the total composition. It also includes setting regulators, hardening, as well as a plasticizer. They allow you to create the necessary consistency of this building material so that it is convenient to work with it. In addition, it is these components that give it all the necessary properties and quality characteristics.

For the preparation of putty, in addition to the above ingredients, many use soap, chalk, flour glue, gypsum, varnishes and some other components. The variety of compositions is huge. Often they also include film-forming substances: chalk, talc and pigments, for example, ocher or zinc white.

The filler in this composition exceeds the number of film formers and pigments. The composition of the filler varies depending on its type. Each specific species includes certain components.

Putty as a finishing material has a number of advantages and disadvantages.

- So, many of the advantages include a viscous texture of this composition. Due to this, the mass is easy to apply on the surface of the walls and evenly distribute it. It does not drip and does not flow. Therefore, it is not so difficult to work with it.

- The next plus is the high rate of drying of the composition. In addition, in the process of drying, this material fully retains its volume. It does not shrink and does not change its external properties.

- The material has a good grip: it does not peel off from the walls and does not fall off. There are no cracks on it, and it is quite durable.

- It should also be noted the versatility of the filler. It is suitable for many types of cladding materials, therefore it is in great demand. With its help, you can easily handle the walls yourself, it is only important to learn some rules of work.

- A big plus is the ability to correct a flaw,which could have been formed in the course of work: if you suddenly flush the walls, you can get rid of the irregularities with the help of abrasives. In this way, walls and other surfaces can be perfectly decorated.

- The great advantages of filler is its budget value. This is especially true of dry formulations. This finishing material will have everyone affordable, moreover, its consumption is not so high. In general, you will not spend a large amount on such preparation of walls and ceiling.

But there are some disadvantages to this coverage.

- So, you need to clearly count the amount of putty before you start using it. It is sometimes quite difficult to do. If you make incorrect calculations, and you have an extra portion of the diluted mixture left, then you cannot use it later. She will have to throw it away. After a couple of hours, the putty loses its usability.

- Sometimes in the process of work there are difficulties. So, you have to wear a thin layer of putty several times in order to cover better lay on the surface. It takes a lot of time, because it is necessary to dry each layer before applying the next. Thus, the work is quite laborious and long.

- The big disadvantage that relates to ready-made types of wet putty is that they have a high cost. To process a wall with this composition is completely very expensive. That is why the finished putty is used only for final finishing in one thin layer.

Many people confuse putty with plaster, but in fact, these materials have a lot of differences.

- So, putty has a special structure. It is considered fine-grained, while plaster is coarse-grained.

- The big difference, which is considered a feature of the putty, is its drying time. This composition dries completely within 24 hours, but the plaster makes it wait for drying for several days.

- An important difference is that in the process of work putty is applied very thinly, but the plaster, on the contrary, is distributed in a thick layer.

- Also, these materials are different and possible grinding. Grind plaster can not be.

- Putty, unlike plaster, is used only if the walls have small defects. Usually, if the differences in height exceed 2 cm, then they use not plaster, but plaster.

- In addition, different methods of applying these materials are used. So, putty, unlike plaster, will not work to spray the surface, and only then distribute. Due to the viscosity of the composition is smoothly and gently applied to the walls and other surfaces using special tools.

- These are completely different materials that are not interchangeable. Both of them have a common function - the alignment of the walls, but first of all plaster is applied, and only then putty as a finish.

It is this order of finishing that allows to achieve ideally smooth and even surfaces.

Purpose

Now the use of putty is very common. It is used for both exterior and interior work both in the apartment and in the house. The putty has good quality characteristics, therefore it is used in many areas. It is used to fill holes and seal joints on walls and other surfaces.

In addition, it can be used to close riveted and welding seams. As a rule, for these purposes use a thicker layer of putty. The thickness of the layer required for finishing work, manufacturers usually indicate on the packaging. In general, different putties have different applications.So, lacquer formulations are applied in the field of mechanical engineering, and materials on a glue or oil basis are used in the field of construction.

Putty allows you to perfectly align the walls and iron them. In some cases, it helps to avoid the cost of expensive plaster. In the process of applying, you can repeatedly alter, constantly leveling the surface, bringing them to the ideal. You can eliminate any errors, until the material is dry, and the quality of finishing work will not fall.

The filler acts as a finishing layer after finishing the walls. After it, you can apply almost any coating. It is ideal for thin layers of finishing materials, such as wallpaper or paint. It is an integral part of the repair of premises, without it is quite difficult to align the walls.

Putty also allows you to improve the adhesion of the decorative coating from the surface of the wall. That is why before applying paint and wallpaper most often used this composition. As a rule, to improve this function and for greater reliability of putty, it is used together with a primer.

It is not always able to provide reliable bonding of the covering layers with the substrate. That is why it is used after a layer of primer.

Kinds

There is a huge variety of putty mixes. They are classified according to different criteria.

The compositions

The composition of the putty is as follows.

Oil-adhesive

This is the most budget type of putty. It is based on a substance called linseed oil. This composition is now not so often used, since manufacturers offer better and easier to use materials.

In general, such a coating is considered harmful, although it is not human health that suffers from it, but the walls and surfaces to which the putty is applied.

So, it has a special composition that can be absorbed even into the densest concrete. After application, it can appear as stains even through a layer of applied paint or wallpaper.

The only option to which it is resistant is oil paints. That is why oil-glue putty is usually used only in combination with these compounds. But the big advantage is the low cost of putty on the Olfo. Because of this, it is often used for decoration of premises for production purposes.

It has a number of other important functions:

- The composition has good waterproofing.

- When applied to plaster, it helps to strengthen the layer of plaster and prevent its destruction from harmful effects. Therefore, with its help often finish bathrooms, sheds, storerooms, garages. An oil paint is applied on top of this composition in these rooms.

In modern construction and repair, oil-glue putty is also used for finishing wooden surfaces. So, it can protect such materials from rotting, and nails in them - from the appearance of rust. Thus it is possible to extend the life of wooden walls.

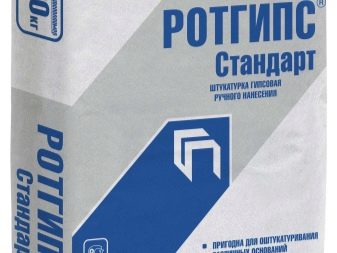

Gypsum cement

This type of putty has a higher cost than the previous one, but it is distinguished by its versatility. It is suitable for almost all decorating. Manufacturers present gypsum cement putty in the form of a dry mixture. In the manufacture of its mixed with water. The cooking process is different from creating a plaster that is dissolved. Putty is mixed.

This putty has a label that indicates its purpose and functionality. Thus, coatings intended for wet rooms are labeled VN, materials for residential premises are labeled LR / KR.Gypsum-cement mixtures are most often used to prepare the walls prior to wallpapering.

This material has several advantages.

- Gypsum plaster allows walls to breathe, creating a good indoor microclimate.

- Non-shrinkable putty resistant and reliable. Even after many years, cracks do not appear on the walls.

- It allows you to make a completely flat surface, thus reducing the cost of finishing materials, especially when you plan to use paint.

- Gypsum plaster dries much faster than other types.

- She has no smell at all.

- Gypsum composition is flame retardant and hypoallergenic.

- It perfectly prepares surfaces for any kind of coating, even for the thinnest. This is due to the fact that after drying the surface will have a perfectly white color.

But gypsum is exposed to changes in temperature and high humidity, therefore it is not the most practical. The surface will not be too dense, a little loose, so chips may appear on the wall from mechanical damage. That is why it is used only in dry rooms of residential type or in heated non-residential premises. An exception is plaster waterproof solutions in which special components are added.

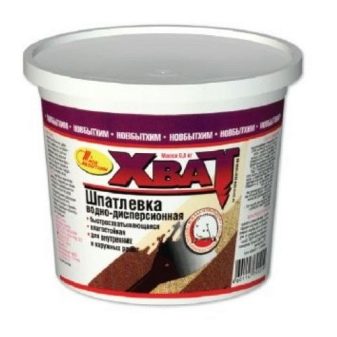

Water dispersion

This type of putty is also presented in the form of a gypsum cement composition, but at the same time it is mixed differently. The coating is sold in a bucket and refers to the finished mixtures. It is pre-mixed with a water-polymer emulsion. This mixture has a higher cost compared to dry, but you do not have to dilute it before finishing the walls. The mixture is ready, you can open the bucket, and immediately put it on the surface.

In addition, you will not have the opportunity to err in the proportions when stirring. The composition already has the right consistency.

But these compounds quickly lose their properties, especially if you suddenly forget to close the bucket. Therefore, such an expensive mixture in about an hour will become unusable.

Although the coating will not harden in an open bucket, the whole mixture will be unsuitable since the coating will later be brittle and unreliable. Water-dispersion putty due to its qualitative composition has an ideal viscosity, so it is easiest to apply. It allows you to create a perfectly smooth surface.

The composition is mixed very high quality, there are no clots and other elements that can spoil the texture of the wall. Even after drying in the process of grinding with the help of a grater, you will not damage this coating: it is quite difficult to make a hole on it.

Ready-made water-dispersion formulations are great for beginners. With their help, even those who work with such a composition for the first time will be able to prepare walls for painting.

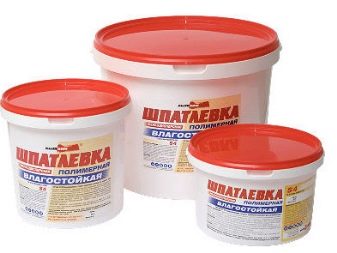

Polymer putty

This putty is sold in bags of 25 kg. It has good elasticity. The coatings are durable and durable. In addition, manufacturers mainly produce waterproof polymer putty, so the walls are well protected from moisture and for a long time are not destroyed.

Approximate compositions have the widest scope in comparison with other types. In addition, they have important technical differences: a ready diluted solution can be stored for about 12 hours, while its properties will not change. Thus, you can take breaks during finishing work, and material loss will be minimal.

But such compositions are distinguished by high cost. That is why You should always pay attention to the ratio of price and quality of the material.

Polymer putty can be of two types: acrylic and latex.

Acrylic are universal because it is suitable for both exterior and interior decoration. Provides a better grip when finishing, resistant to natural factors. Acrylic putty is used mainly as a finishing compound, because due to its texture you can create a smooth surface.

But the layer of this composition on the wall should be no more than 1 mm.

Acrylic polymer filler is applied even on wooden surfaces. She soaks them well. Such putty is non-toxic and absolutely harmless to human health. Acrylic blends can be stored for quite a long time, which once again confirms the cost-effectiveness of the consumption of this tool.

But poor quality paint doesn’t fit on acrylics because the walls are too smooth for them. That is why for such finishes it is better to purchase more expensive and high-quality paint and varnish compositions.

Latex polymer composition is used only for interior decoration of residential and industrial premises.. Paint is convenient to use in the apartment.It collapses under the influence of low temperatures and can create cracks. But the material under the conditions of its operation comes out quite strong and durable.

Due to the plasticity it is convenient to apply on the wall, it is also suitable for beginners. The composition is odorless and does not emit harmful toxins. Due to the versatility of latex fillers, it is suitable for many surfaces, including concrete, metal, drywall, wood.

Also there is a polyester putty and composition with fiberglass for exterior decoration.

Readiness classification

Putty mixes are sold either in ready-made form, representing a solution, or in the form of dry mixes. They are very different in their quality characteristics, price and many other criteria.

Dry mixes

These compositions are presented in the form of a powder, which is diluted with water before use. When breeding it must be thoroughly kneaded with your own hands or with the help of a drill with a nozzle - a mixer. It is important to obtain a high-quality homogeneous consistency, so that the solution fits well on the wall and does not form irregularities.

Although the cooking process may take some time, it is worth it. You will be able to prepare a solution of the density necessary for you, adding more water. This way it will be easier for you to work with it. The cooking process itself is fairly simple.

Dry mixes are much cheaper than ready-made. They can be stored in dry form for many years. A big advantage is also the convenience of transportation. A bag to bring home is much easier than a few buckets of ready-made mortar.

But there are some drawbacks. In order for the solution not to lose its properties during the application process, it is necessary to knead it in small portions, which takes more time.

Some inexpensive formulations must be used within 15 minutes. Thus, not every newcomer will cope with leveling the walls so quickly. Although the mixture is stored for a long time, but when exposed to moisture, it can completely deteriorate. After all, the manufacturer produces these formulations in cartons.

Ready-made compounds

In finished form is sold liquid putty. Usually it is presented in the form of a prepared mixture and is packed in a plastic bucket. In general, liquid formulations have a latex, dispersion, polyurethane base.

The finished solution is stored much longer than the mixed dry. This is due to the fact that the composition includes special substances that delay drying. But on the wall the coating dries out pretty quickly. You can use this material immediately after you open the package.

The finished mixture has a higher plasticity and provides better adhesion. You do not have to use tools for stirring and waste your time. In addition, if you have left the finished solution, and you hermetically close the packaging, you can use it again later.

Purpose

Putty can have a different purpose. And it usually depends on its composition, as well as the grain size.

Starting putty

It plays the role of the main layer before finishing the walls. Its main difference is in a larger grain size compared to decorative finishing layers. This feature of the structure determines the complexity of grinding. As a rule, after applying a layer of starting putty the wall becomes rough. That is why this layer has to be refined with subsequent coatings.

Starting putty allows you to fix irregularities on the surface of the walls, as well as fill small cracks.It is great in case you want to make a brick or concrete wall. It dries much faster than other types of putty and is more durable. It is this putty can be applied with a layer thickness of up to 2 cm.

Starting putty is not always necessary to cover the following layers. It can be used as the penultimate layer before applying wall panels, as well as thick and heavy wallpaper. But if you want to decorate the walls with paint or thin wallpaper, then you need to apply other layers of putty.

Finish line

The purpose of this type of putty is to complete the preparation of walls for applying decorative coatings. It has a consistency similar to a batter. That is why it provides perfect smoothness of the walls. It is applied with a layer of less than half a centimeter, the thinner the layer, the better the coating will look. If you apply it with a thicker layer, the solution may shrink, cracks will appear on it.

It is simply impossible to apply a thicker layer, because due to the watery consistency the mass can float. It is convenient to grind this structure, but after that the covering can form a lot of dust.It is not as strong as the starting putty, but better quality. It is absolutely not suitable for smearing cracks.

Typically, such a putty is not applied at one time, each layer is about half a millimeter. Dried coatings will look like polishing, they do not even always have to be polished.

Universal putty

She can replace the two previous types of putty. Its purpose is leveling and restoration of surfaces. It is suitable for almost all types of bases and allows you to create several layers: base and finish. With its help, you can even carry out structural decoration. It has a medium consistency and a universal composition with a high degree of adhesion.

Make up includes a lot of modern components and is quite expensive. Mostly universal blends are of high quality.

Specialized putty

It includes special additives for specific purposes. So, some mixtures are needed to hide the joints between the panels. They can replace reinforcing tape. Also, there are models of elastic type, suitable for the so-called breathing cracks.

Specialized putty can be expanding. It perfectly performs the function of urgent repair. These are the most durable and reliable types of putty, because only high-quality elements are included in the composition. As a rule, the manufacturer indicates on the packaging the specific purpose of this type of putty mixture.

With its help, you can solve a number of problems arising in the process of repair. For example, it can be applied to fiberglass.

Manufacturers

Now among the buyers is popular brand composition Semin. Customer reviews show that this is a versatile and flexible putty that is even suitable for applying decorative plaster called "Bark Beetle".

Buyers also praise dry putty "Uniflot", indicating that it is ideal for flooring.

Buyers like ready-made compositions for finishing brands Novol and Hercules.

Brand compositions are also popular. "Tex". The manufacturer provides adhesive and oil, latex and moisture resistant putty for both dry and wet rooms.

Which one to choose?

If you do the repair, then choose the putty of the same brand as other finishing materials.Experts believe that the compositions of one brand are better compatible and work well with each other, complementing and providing good adhesion. When buying, always try to take into account the purpose that the manufacturer indicates on the package. TIn any case, models for leveling walls should not be used as finishing ones; for this purpose, it is better to purchase smoothing compounds to create an even layer.

Also consider the operating conditions of these formulations. For wet rooms it is necessary to select formulations with appropriate labeling on the package. Also consider the temperature conditions in the room where you plan to put it. Not every putty will withstand frosty conditions.

When choosing you need to accurately calculate the required amount of putty in order to buy the most appropriate for your calculations the amount of the mixture. This way you save money and you don’t have to throw out the ready diluted solution. If you plan to paint the walls, it is better to buy ready-made liquid mixture. They allow you to create a better finishing layer.If you plan to glue the walls with wallpaper, then you can save on the putty - buy a dry mixture, spreading it at home alone.

When buying, try to open the lid and check how qualitative and homogeneous the composition is if you get a liquid putty. If you see irregularities and dry blotches in the composition, it will lie unevenly on the wall.

Cement types of putty with a certain amount of sand in the composition are perfect for exterior decoration, but for interior decoration, they are not suitable because they are not so durable.

If you are planning to cover the wall with light paints or wallpaper, then purchase only a perfectly white putty. Otherwise, its shade may adversely affect the final color of the trimmed wall.

If you paint walls, you may have to increase paint consumption by applying several more layers.

If you do not know which putty to choose, then pay attention to the universal composition. Thus, the risk of choosing the wrong product will decrease. Many masters in building and finishing works recommend acquiring acrylic compositions for independent use, since they allow you to best prepare the wall for further finishing.

Also, when buying, study the composition of the putty mixture. It is better if it contains additional substances and elements that improve its characteristics. When buying, also study for what material and wall color this composition is suitable, because not all coatings can be used for working on concrete, for metal. For finishing of corners and other hard-to-reach places it is better to use specialized types of putty.

Cooking

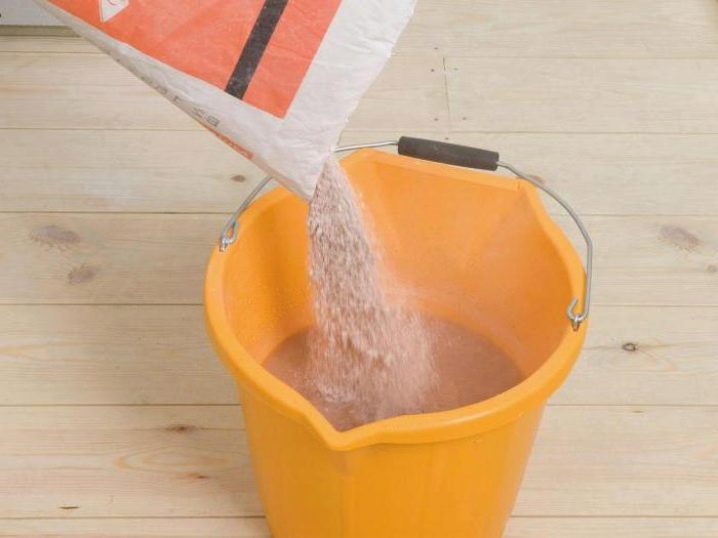

Not all types of putty require cooking. It will be necessary to plant only dry mix. To properly prepare this composition, you need to gradually dilute it with water. First, the construction bucket should be filled to a quarter with clean water at room temperature. Then the dry mixture must be gently poured into the water in a thin stream so that it completely covers it, and a small hill forms above the surface of the water.

Then you need to wait about half a minute until the composition is completely soaked with water and settles down. It is important that during the rash did not form dry lumps. After the composition has passed, it is necessary to stir the composition with quick movements for a couple of minutes.

It is possible to use for this purpose both handy elements, and specialized construction. Ideal drill with a nozzle in the form of a mixer.

After thorough mixing, wait 2 minutes and then mix again for two minutes. So the mixture will be ready for use.

Dry mixes have some nuances in the cooking process. So, they can not be diluted with water after you have already prepared them. Drip the dry composition in them is also unacceptable. If you are uncomfortable to apply the composition, and it drains, then you can fix it only with an abrasive or spatula. Mixing must be done in portions so that the mixture does not dry out. Examine the shelf life of the finished composition shown on the package to calculate the finishing time.

Application features

Putty can be applied in different ways, including machine. The method varies depending on what the final decorative coating will be. If you plan to cover the walls with wallpaper, then the putty should be applied with a wide trowel of parallel strips, overlapping them at each other by about 20%.The spatula should be kept strictly at an angle of 30 ° with the same pressure so that the layer has an equal thickness.

If you reduce the angle of the spatula during application, the layer will be thicker, and if you increase it, it will be thinner, but torn. After applying an even layer of putty it is necessary to dry it, and then remove the overlap with a special trowel.

At the end of this process, it is necessary to check the smoothness of the coating. For this it is better to use a level with a laser.

After that, all mounds are cleaned with abrasive, as well as gloss over the formed holes. You may need to take two or three approaches in order to completely level the wall. After that, you need to give the wall to dry completely, and then wipe it with a jointer with the mesh number 80. You need to move in a circular motion with a little pressure. After such a final processing, you must wait a day, and then you can already glue the wallpaper.

Putty under the paint is applied by the same procedure, but after the final alignment and jointing with a jointer, it is necessary to additionally cover the walls with a finishing layer of plaster. It should also be wiped and then primed. Marble plaster may be the last layer.

Useful recommendations

For many, the process of filling the corners is difficult. There often remains an excess amount of this material. Experts recommend rubbing it with abrasive, but it is not always convenient to do it.

After applying the putty must leave an angle free. After that, you should gently squeeze out the putty using a special tool in a continuous movement from the bottom corner to the top. Then you need to use a special spatula. You need to walk them, leaning on the wall to create the perfect cover. Then you should wait until the coating is dry, and get rid of irregularities.

Some recommendations of the experts give and in order to properly putty slopes of the room. So, they are trimmed with an angled spatula, and then the nodules are removed with an abrasive. But this work is somewhat similar to trim angles. The only feature is that the process requires at least two approaches. Each time the smoothness of the coating must be checked using the construction level.

To learn how to quickly and accurately putty walls, you will learn from the following video.