Latex putty: advantages and disadvantages

Putty is one of the most popular materials used for leveling walls and ceilings.

Among a wide variety of putties, a latex-based compound is particularly popular. Such material possesses high technical characteristics, and also is convenient in work. The advantages and disadvantages of this coating will be considered in more detail in this article.

Special features

As in all putty mixtures, the composition of the latex coating includes:

- various fillers;

- special substances that give plasticity and elasticity to the material;

- additional additives that give the material certain properties.

As the main component in the manufacture of latex coatings, an emulsion of dispersed polymer particles in aqueous solution is used. There are several types of latex, and depending on what type was used in the production of putty, will depend on the characteristics and properties of the mixture.

Special components, for example, antiseptics, are often added to the latex putty. Antiseptic additives allow you to use this material in rooms with high levels of humidity, since the resulting coating will be resistant to the formation of fungus and mold.

Kinds

There are no big differences in the produced latex mixtures. Depending on the composition and manufacturer, some material properties may vary.

In the form of release there are the following types of products:

- ready to apply solution;

- dry mixes from which it is necessary to make a solution independently.

Latex putty is available in a wide color range, which makes it easy to choose the right shade. In addition, latex mixtures differ from each other in terms of output.

The scope of the following formulations:

- for interior decoration;

- for outdoor construction work;

- universal blends;

- for dry rooms;

- for wet rooms.

Advantages and disadvantages

As with each type of putty mixture, the solution based on latex has its own advantages and disadvantages.

The advantages of this composition include the following properties and characteristics:

- The coating is characterized by minimal shrinkage.

- Some types of latex coatings are resistant to temperature changes. This property allows you to use the material not only for the interior, but also for the exterior walls.

- Resistance to precipitation.

- A wide range of different shades.

- High adhesion rates with various materials.

- Due to the viscous consistency of the solution easily penetrates and fills cracks in the surface.

- When drying forms a high strength coating.

- Good elasticity.

- Excellent as a base for painting. This coating does not absorb paint and varnish solutions, which allows to reduce paint consumption during finishing.

- Ease of construction work.

- The resulting coating is not covered with cracks and not showered.

Despite the impressive advantages of latex putty, it also has its drawbacks.

Consider the main disadvantages of the material:

- The prepared solution should not be exposed to low temperatures. When freezing, the material loses some properties. Therefore, even if the solution is thawed, it will already be unsuitable for use.

- The price of such coverage exceeds the cost of many types of putty. However, this material can be applied with a layer one millimeter thick, unlike acrylic or cement putty, which can significantly reduce the mixture consumption.

Scope of application

Latex putty can be used for both exterior and interior construction work. The mixture has good adhesion with almost all materials. Metal surfaces in this case are the exception - they are not recommended to putty latex mixtures.

Latex composition is well suited for the following materials:

- wood;

- drywall sheets;

- concrete;

- plastered surfaces;

- brick walls.

The scope of latex material is not limited to the alignment of surfaces.

This mixture is used for the following purposes:

- creation of a base for painting with alkyd enamel, oil formulations or water-dispersion solutions;

- sealing of drywall joints;

- elimination of cracks and various defects on the surface;

- filling of slopes of window openings;

- repair and restoration of wooden structures;

- creating different textures on the surface;

- papier-mâché trim.

Manufacturers

Before buying latex putty, you should pay attention not only to the composition and characteristics of the mixture, but also to the manufacturer. To purchase quality material, you must first familiarize yourself with manufacturers who have proven themselves in the market of finishing coatings and study the reviews on their products.

"Tex"

The company "Tex" is one of the largest Russian manufacturers of building materials. The company offers high quality products at affordable prices, including latex putties. Latex-based blends are available in two versions:

- Tex Profi;

- "Universal".

Putty "Tex Profi" is designed for interior walls and ceilings in order to align before applyingfinish coating. The material is suitable for application to concrete, plastered walls, fiberboard and plasterboard sheets.. Available in white with cream or gray shades. The mixture is sold in ready for application form in containers of both small volume (1.5 kg, 5 kg, 8 kg) and in large buckets weighing 16 and 30 kg.

The mix "Universal" is also intended for carrying out finishing works indoors. The solution is applied to the surface before painting or wallpapering. Plaster "Universal" has a high drying speed. Drying time under favorable temperature conditions is four hours. The mixture can be applied to the surface with a layer one millimeter thick.

The high quality of the Tex latex mixture was appreciated both by consumers who did not have experience in working with putty and by the master of finishing construction work.

Among the advantages of the material are the following properties:

- low price;

- ease of application;

- economical consumption;

- creates a durable coating;

- soft elastic consistency;

- no unpleasant smell.

Some buyers note that the mixture is poorly tinted, which is the main drawback of the material.

Profilux

The trade mark Profilux is part of the German concern Meffert AG Farbwerke.High quality finishing materials are produced under the Profilux brand.

Latex putty is produced under the name "Profilux Profisheet". This material is produced ready for application. Used to level various indoor surfaces.. Allows you to get a perfect white finish. After drying the mixture forms a durable coating that is resistant to moisture and mechanical stress.

Putty «Profilux Profisheet» can be used to create a finishing coating. The mixture seals well up various defects on the surface, small cracks and seams. The drying time of the solution can be from four to six hours.

Buyers highlight the following benefits of this product:

- the resulting coating is easy to sand;

- flat smooth surface;

- good adhesion;

- easy to apply;

- dries quickly.

Lacra

Lakra firm has established itself well on the Russian market of building materials as a manufacturer of high-quality paint and varnish products. All materials produced under this brand comply with international quality standards and are environmentally friendly.

Latex putty company "Lakra" is issued under the name "Choice of the master." The composition of this material, in addition to the main components, includes antiseptic additives, which makes the coating resistant to the appearance and spread of fungus and mold. The mixture is designed for interior walls and ceilings before applying the final coating.

Buyers point out the following material benefits:

- low cost;

- lack of smell;

- high drying speed;

- convenient consistency;

- well aligns the walls.

The disadvantages of putty "Choice of the master" include uneconomical consumption of the mixture.

"Optimist"

The Optimist group of companies is another popular Russian manufacturer of paints and varnishes. The company offers a wide range of high-tech building products.

"Optimist" also produces a latex water-dispersion mixture. This material is designed for interior decoration in dry rooms. The mixture is used to eliminate cracks and irregularities on the surface before applying the final layer.

As a finish, you can use wallpaper, paintwork materials or other decorative mixtures.

Putty "Optimist" is available in white color ready for application.The material has a low frost resistance and can withstand five cycles of freezing at a temperature not lower than -25 degrees. This property allows to transport the mixture at low temperatures.

Buyers note the following advantages of this composition:

- low consumption per square meter;

- high level of plasticity;

- health safety;

- fire safety;

- excellent adhesion;

- The resulting coating is easy to sand.

The disadvantages of the solution, above all, include the high cost.

"Hermes"

The firm "Hermes" appeared on the Russian market of finishing materials not so long ago, but already managed to firmly occupy its niche. Hermes products are distinguished by good quality and competitive price. The company produces materials for various finishing and construction works.

Silicone plaster "Hermes" is produced in the form of a dry mixture. The material can be used in rooms with normal and high humidity before applying the final coating.

Consumers distinguish the following advantages of this mixture:

- low price;

- good moisture resistance of the coating;

- great for painting;

- good wear resistance.

The disadvantages include the form of release of the material: before finishing works, it is necessary to prepare a solution from the dry mixture independently.

How to breed?

Ready-to-apply latex mixtures are easier to use, as they do not require additional efforts and time-consuming to make a solution. However, dry mixes are cheaper and enjoy no less popular. Bred powdered putty in ordinary water in proportions of one to one.

No need to prepare the solution at once from the entire amount of plaster in the package. In the capacity for putty it is necessary to fill a small amount of dry mixture. Water is added to the material, while constantly stirring.

After the mixture is well mixed with water until a homogeneous consistency, you can begin the finishing work. The finished solution can be used within an hour, after which it will harden and become unusable.

Application Tips

Before proceeding with the repair work, it is necessary to prepare the treated surface well. From the base under the putty removes all dirt, after which the surface must be primed.The primer should be completely dry, only after that it will be possible to proceed to puttying the surface.

The latex mixture is not toxic, but some people may have an individual intolerance to any component in the composition. Before starting work, take care of your own safety measures.

Skin contact should be avoided with a putty; therefore, it is best to work with gloves. When carrying out interior work the room must be aired.

Before applying the putty on the surface of the mixture must be held for some time in the room. It is advisable to bring the solution into the room a few hours before work begins, so that the temperature of the mixture adapts to room temperature.. Then a small amount of putty must be poured into a separate container. Too thick mixture can be diluted with water. A bucket with a ready-made composition should be tightly closed with a lid to prevent the mixture from drying out.

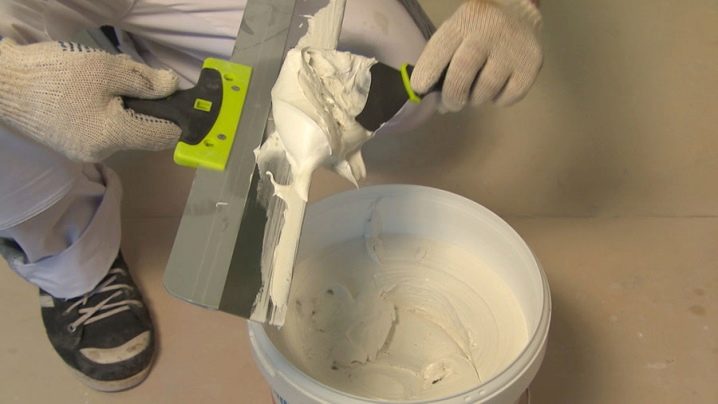

Apply the material with a metal spatula. The thickness of the layer should not exceed three millimeters. Since the mixture has good plasticity, almost any person can cope with its application, even without having experience in such work.

If you need to make several layers of putty, before applying each subsequent layer, you must wait until the previous one is completely dry.

This time may differ for mixtures of different manufacturers, so you need to look at this information on the packaging. Most often, the coating dries from 2 to 6 hours.

When conducting outdoor work requires certain weather conditions. It is impossible to putty external walls when it rains or when exposed to direct sunlight.. The smoothing of the putty surface to give the ideal smoothness to the coating is carried out using a sponge grater.

About the secrets of puttying walls with your own hands you will learn from the following video.