Paint mesh for putty: purpose and types

An important component of the finishing work in the house is the putty of the walls. Their flat surface is necessary for further repair. Using plaster does not help achieve the desired result. Therefore, the use of reinforcing mesh is an excellent way out.

Reinforcement Mesh Features

Before using paint and varnish coatings, it is necessary to achieve a perfectly flat wall surface. It depends on how strong the foundation will be, whether cracks and other defects will appear on the walls, the appearance and duration of operation. The main role in this area is the painting grid. It protects the finish from detachment and deformation, as well as from adverse external influences.

The paint grid is moisture resistant, well withstands exposure to temperature, non-toxic. It can be applied with a large number of materials, such as drywall, concrete and others.The material is impregnated with a polyacrylic composition to maintain its strength and enhance adhesion to the surface.

When finishing work used reinforcing mesh of polymers and fiberglass. They are lightweight and therefore easy to use. If the plaster is applied with a layer not exceeding 2 millimeters, you can do without a grid. Their use is necessary when the layer is from 2 to 5 millimeters.

The material should be well secured. This can be done with nails, dowels or screws, depending on which surface you are working on. Otherwise, the plaster may peel off or deform.

Main types

Paint nets are divided into types corresponding to the size of the cells. For smaller cells, the softest material is used. There are the following types:

- wide glass cloth grill;

- serpyanka;

- spider web

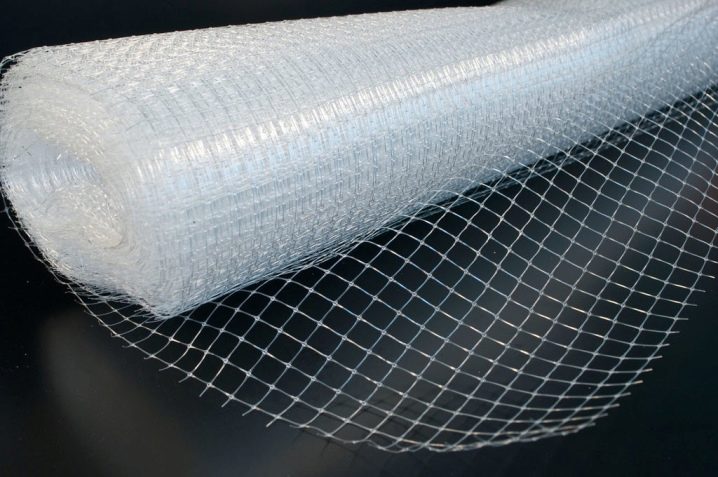

Wide glass cloth mesh

The design has a cell size of 2 to 2 mm. It has anti-corrosion properties and anti-shock effect, resistant to alkalis. Good withstands moisture and temperature extremes. Most often produced in a width of 1 m.

This type of paint mesh is used in the finishing of ceilings and walls. Due to its properties, it protects the surface from the appearance of cracks and other deformations in subsequent work, since the design is well resistant to mechanical stress.

Serpyanka

The main properties of the product are identical to the previous type of paint mesh. Serpyanka differs in width. It can be from 4.5 to 25 cm. The length can be up to 20 000 cm. In some cases, one of its sides has an adhesive layer.

Serpyanka is widely used when working with gypsum plasterboard, for processing corners and joints and for corner reinforcement of putty. With its help, you can strengthen the slopes on the windows and doors. Well masks the deformation of the surface and possible cracks.

Gossamer

This type of grid is also called painting fiberglass. Very thin design can be used for delicate work, where a wide network due to its thickness will be inconvenient to use.

This type is ideal for large surfaces due to the fact that it is laid in wide rolls. Increases plaster coupling with material. Mainly used when performing ceiling work.

Application

The reinforcing material is stacked fragmentary, so it must be prepared in advance. To do this, the material is cut into pieces of the desired size, and already these parts are applied to the plaster in the direction from the center to the edges. The edges of the mesh should not stick out, so they overlap as carefully as possible.

The technology of overlaying grids is very standard, it does not depend on the specific types:

- The prepared coating is primed.

- Putty need to be laid only when the plaster dries completely. But the reinforcing mesh is placed while the putty has not dried yet.

- Next, apply the grid, which is fixed and pressed into the base with a spatula. On top of it is applied the finishing layer of putty.

Nuances appear when using the serpyanka grid. In this case, the joints are cleaned and primed, dried thoroughly, and the material is applied on a dry surface. After that, it is overlapped with a putty, which is aligned as much as possible.

Serpyanka can be applied in two ways. In the first, it is attached to the surface, pre-smeared with glue, carefully pressed, and then covered with another layer of adhesive.When the surface dries out, it must be puttied again. This method is not very popular, since the quality of work may turn out to be unsatisfactory.

In the second embodiment, the paint mesh is superimposed on the putty, fixed on it and immediately covered with a second putty layer.

When working with fiberglass, you must use a roller. With it, a sticky compound is applied to the material, after which the strips are attached with an overlap. A roller is also used to align the web. Before work, it is necessary to properly primed the surface.

To fix the reinforcement putty in the outer corners of the room, the masters use the corners with attached fiberglass. This gives greater resistance to mechanical stress, possible during operation. Fiberglass can be used to reinforce the inner corners.

Grinding

After the walls are reinforced and the reinforcement work is finished, a finishing putty is carried out, which does not differ from the main one. The material is applied in a thickness of about 1-2 mm.

It is necessary to pay attention to drying the layer with the painting grid. If this layer is not completely dry, the material will not stick.

Next comes the time of grinding. You can spend it no earlier than 24 hours. The appearance of the room depends on how smooth and smooth the walls look. When applying paint or wallpaper on a deformed surface, defects will be evident, and the impression will be ruined. Wallpapers can wrinkle, and paint - look sloppy.

It is sanding that helps to achieve the perfect smoothness of the coating. It should be carried out in good light to notice even the smallest irregularities and flaws. For work the grinding sponge is used. It can be replaced with emery paper, at first coarse-grained is used, and fine-grained will be suitable for final polishing.

It is necessary to thoroughly treat the surface completely. there should not be even the slightest projections. It is possible to putty relatively large cavities. It is also possible to grind using an abrasive mesh. Its price is slightly higher due to the many positive qualities. For example, the grid has a stronger wear resistance.

In the presence of a grinding machine, you can speed up the work.The result in this case may be better.

The final stage after grinding is thorough cleaning of surfaces. Next you should make the final primer. After that, the coating is ready for final finishing work.

You will learn how to avoid mistakes and properly putty the surface in the following video.