Automation for sliding gates: tips on choosing

The main difference between sliding gates from other systems is operational simplicity. They are easily controlled manually or with a button. The design is very high reliability. Automation of sliding gates has some special features, so it is worth exploring it in more detail.

Special features

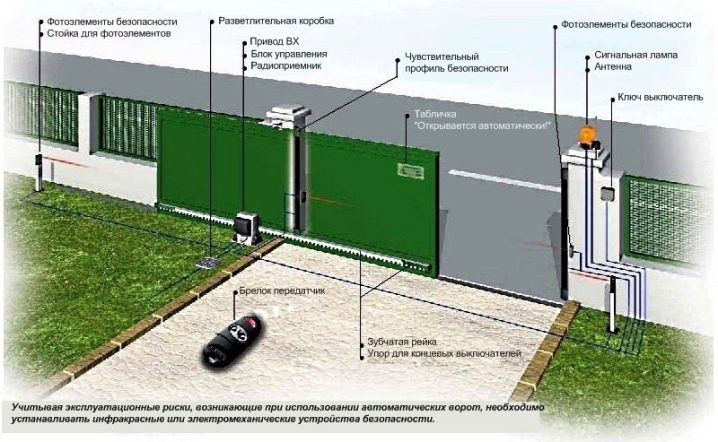

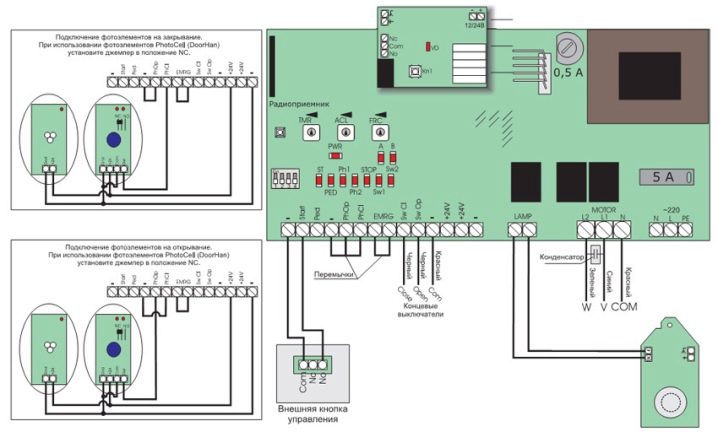

Electric drives include various electronic and mechanical components. They, in turn, are responsible for different functions. Automation works properly due to a well-coordinated work mechanisms. The controlled movement of the sliding gate is provided by the following nodes:

- motor gearbox;

- bar with teeth, which gives the gain from the motor to the structure;

- drive unit;

- control chains.

The inclusion of the automatic system occurs at the time of closure of the contacting elements. With the closure of the data is transmitted to the control chain engine. The motor action begins at the point when the transmitter from the key fob / remote controller hits the mother device.

At the time of moving the door leaves to the desired point, the motor stops due to the signal given by a special sensor. After a certain period, a temporary relay is connected, the gate closes. This feature electricians acceptable for any gate: sliding, lifting, other. Automation of the closing process requires the installation of a time interval. Until the point of initial position is reached, the engine is not switched off.

The above-described composition of the automation of sliding gates can be characterized as a minimal, but sufficient set. As additional elements include:

- Photo cells. Their main purpose is to stop the operation of automation when an obstacle appears in the doorway.

- Signal lamp. It flashes when the automation drive is running.

- Remote antenna system. It increases the range of signal capture console.

The main component of any set of automation - the engine. Variants are suitable for a three-phase or two-phase meter. Experts recommend a three-phase variant with a star-winding connection. This will contribute to a better starting ability of the engine, which means thatAutomation will be as efficient as possible.

If there is no three-phase meter, a single-phase capacitor motor will do. The performance of this device below. The difference is especially noticeable when starting the automation. For example, the value of a capacitor type motor will be from 1 to 2.5 kW. The engine rotational speed is from 500 to 1000 revolutions per minute.

The number of rotations of the drive wheel should not exceed 100. If the automation scheme is assembled manually, the best option is to use single-stage gearboxes.

System parts are usually expensive, but there are replacement options. As the main constituent element can act as a power motor from the washing machine. When connecting the engine, it is important to correctly determine the ends of the windings. Measure the resistance force with a multimeter. Start winding will be more important.

Replacement gearbox will belt drive. Pay attention to the mechanism with an independent shaft, it should be two bearings. Center the shaft correctly, as two transmissions are mounted on it.

Criterias of choice

The gates of a private house do not have a large load; therefore, powerful engines are usually not chosen for them. For trouble-free use, engines for a weight of 800 to 1,200 kg are suitable every day.They are usually connected to a conventional 220V meter, therefore, they are economical. The weight of the gate for such automation will be from 200 to 400 kg, and the width of the opening - 4 m.

Manufacturers usually offer a line of devices that correspond to a certain weight of structure. It remains to understand the technical information and select the appropriate model if the improvised manufacture of the structure is not included in your plans.

When choosing gate automatics, it is important to pay attention to the quality of fittings. From it will depend on the ease of movement of the sash. Also with the accessories interconnected drive stability.

Stability is an important advantage of purchasing kits over homemade ones. Another advantage can be attributed to the noiseless operation of debugged set mechanisms.

The main criterion for choosing automatics is device power. Another indicator - the intensity of opening and closing. Choose power according to the principle: the heavier the design, the stronger the system. The choice is influenced by the size of the door, the thickness of the metal, the number of ribs. For a 300 kg sash, a 250-300 W system is suitable. If the design weighing 100 kg, the automation should be at least 600 watts.

If the retractable structure is made of solid material, calculate the load force, taking into account the wind.The standard multiplier is four. To apply it, multiply the weight of the gate by 4. This will be the maximum load on the device. Consider the intensity of the use of the gate.

If the equipment is selected for a private area, performance is taken into account at the rate of 50% intensity. In order for the equipment not to fail quickly, it is important to correctly relate all the characteristics of the product.

Other selection criteria:

- weather characteristics;

- quality of construction;

- parameters of mounted counterweight.

The climatic conditions of the regions are important to consider, since high humidity and precipitation affect the electrical parts of the system. For example, in the conditions of Siberia, it is required to install additional heating for the gate automatics. The selected mechanics should work without any problems in harsh climatic conditions.

The quality of the design will adjust the possible timing of the engine. If the hardware is expensive, good, there will be a fairly low-powered engine. He will successfully cope with his duties. If the parts are of poor quality, the structure will open with great effort and difficulty, it is important to choose an engine capable of withstanding mechanical loads.

Counterweights affect the maximum possible length that the slider can pull. As a rule, this is approximately 75% of the length of the gate itself. Selecting automatics, do not forget to fold the dimensions of the counterweight with the gate length. These will be the minimum parameters for the capabilities of the selected automation.

Operating rules

The service life of the installed automation will be affected by proper operation. Proper use enhances the flawless operation of the gate for many years. Besides, proper use of automation ensures the safety of all others.

For example, experts consider it an extravagant act to attempt to pass under the closing flap. Although the system is equipped with photocells, they practically do not ensure the safety of such actions, as some systems are equipped with a high-speed engine.

In order to avoid injuries or other problems, many gate owners with automatics glue appropriate warning stickers on the structure.

Automatic systems are often equipped with an add-on such as a manual drive. Its action provides the opening of the gate at the time of the absence of electricity with a cable.

The simultaneous operation of two engines disables even the most reliable design.Both options should work separately. In addition, actions with the simultaneous inclusion of two drives are not considered safe. In order not to damage the automationit is not necessary to push, press or in any other way try to correct the situation if the structure does not close or open. Most likely, an obstacle appeared in the way of movement. Initially, understand the reasons, and then take up the repair.

Periodically maintain the sliding mechanisms. The rules suggest that after a certain number of cycles. Carefully read the instructions or invite installers. Purchased drives are completed with detailed instructions not only on the rules of operation, but also on installation. Usually the documentation is multilingual.

Any faulty doors can not be used in conjunction with automation. You risk not only design, but also mechanisms.

Experts recommend testing mechanisms with infrequent home use of the structure. For example, check the button, key switch, photocells, emergency installation button, chain tension.

Manufacturers

Modern and domestic and foreign manufacturers offer different sets of sliding gates. The mechanisms of each brand differ in their features:

- For example, mechanisms are famous for their popularity. Hormann (Germany).

- Italian systems Came suitable for home use. The products of the concern are in demand and considered to be very reliable.

- Another well-known manufacturer - Nice. Its products are distinguished by good protection from intruders, high-speed engines, and safety.

- You can choose the most popular brand kits Doorhan. Automation this brand produces the most diverse, it is made from high quality materials.

- In addition to Italian manufacturers, the market has a high rating of Chinese products, for example, companies Faac. Systems are hydrodynamic, and therefore reliable. However, in comparison with electromechanical engines, Chinese options require more thorough maintenance.

- From other manufacturers, users mark Sommer, Alutech, Game, Stillmatic. These are companies from China, but they differ in high-quality products with good performance characteristics.

Overview

Consider the models of some brands in more detail. For example, systems Doorhan notable for low noise and stable operation. Buyers can choose from an extensive range of options. The effectiveness of automation is possible at temperatures up to -20 degrees. As an option, the manufacturer offers light bulbs, embedded sensors, blocks and remote controls.

The brand drive is allowed to be used quite intensively, since the engine and gearbox are placed together and provided with liquid lubricant. Stability and uninterrupted operation depends on improved protection systems. The drives have good provision from dust and moisture. The price of automation is acceptable.

Manufacturer Faac also offers buyers a variety of models. The equipment combines excellent quality and high performance.

The equipment is notable for its efficiency due to the oil bath in which the microprocessor units are located. Branded grease is an obstacle to problems, even with 30 degrees of frost. Therefore, the products of this company are successfully operated in the harsh conditions of the Russian North and Siberia.

Nice represents on the market lever and linear engines. The system is an excellent design, easy to use, safe.Drive models are economical, while effective at temperatures from -20 to +50. Automatic equipment is supplied with convenient adjustment, reliable accessories. Embedded software allows you to monitor the status of their systems.

Reviews

According to user reviews, it is not difficult to buy automatic systems today. Systems are traded in construction supermarkets of the capital and other cities. Residents of suburbs easily use the services of online stores. Moreover, as buyers say, it is cheaper to order products through online stores. The purchase will have to wait and pick up after some time in the mail.

Positive characteristics are provided by remote-controlled automatic systems.. It is more convenient to operate such mechanisms, without leaving the room or from a car. According to user reviews, the worm type of mechanism has the greatest facilities. If compliance with the aesthetic appearance of the territory is required, users recommend considering underground mechanisms.

If several options are compared at once, it is better to give preference to the amount of traction force, rather than the greater weight of the gate.

The selected automation of sliding gates should last steadily, and therefore differ in reliability. With the right choice of kit, setup and installation will not take long. In this case, even the most inexpensive set may differ in a number of advantages. The price of automatic sliding gates is calculated from purely individual characteristics.

Automatic systems increase both convenience and safety of their use. With the device, the gate is more securely locked in the closed state. Due to reliability, the service life of the structure itself is increased. An important recommendation when installing automation is follow the installation instructions from the manufacturer exactly. Setting it simplifies the task of installing the entire system.

Experts recommend the use of special mounting spare parts for installation. Rivets are equipped with rubber gaskets, which increases the decorativeness of the product.

Do not use welding if the gates are made of profiled sheet. it can damage its protective cover. Still experts do not recommend installing the upper catcher simultaneously with the corners. In this case, the lower catcher is mounted with the shutter closed.During installation, the end rollers are combined with it.

Following the general recommendations of the installation will allow you to quickly and accurately install an automatic system with any characteristics in your yard. And the correct choice of the manufacturer and the type of device will save you from problems with operation and subsequent maintenance and repair of the whole mechanism in the future. Follow the instructions and the automatic gate will serve you for a very long time.

For instructions on how to set up the console to the Doorhan drive, see the following video.