Sliding gates: how to make your own hands

Retractable gates provide not only entry and exit from the local area, but also allocate land among the neighboring houses. Gates can indicate the tastes and financial situation of the owner, can protect against unauthorized entry. In this case, you can significantly save on the installation of sliding gates, if you make the installation yourself.

Kinds

Retractable gates on the principle of control are suspended, cantilever and moving along the rail. In addition, they are divided into single-leaf and double-leaf structures, the latter, by the way, are more expensive, since installation will require twice as many fittings. It should also be noted that the sliding doors made of metal are solid, they are also called “deaf” and latticed. Latticed products, in turn, are divided into products of either mass production, or custom-made - forged.

The suspension system is least likely to be installed, and, as a rule, in industrial plants or in commercial territories. The movement of the door leaf at the expense of the top beam, which is somewhat similar to the rail. Directly on the metal beam are rollers.

The advantages of such a system can be considered ease of operation, durability, and due to the fact that the whole process of operation of the mechanism is arranged in the upper part of the gate, the lower part remains free, respectively, depending on weather conditions.

Perhaps the main drawback of such a system can be considered the height restriction. If it is necessary to enter the fenced territory of a heavy truck, with high probability it will not pass.

The situation can be rectified by raising the bar by 1.5 m, but this will require an increase in the supports, and this is a big financial cost.

As such, there is no height limit for sliding gates moving along the rail. The rail is mounted on the surface for which the concrete base is poured. The roller is welded to the canvas, which slides along the rail.

Often this kind of sliding gates installed in the private sector. They are held in open form by means of a metal frame.In this case, the sash can be open or closed, and through the blind canvases will not be viewed the territory of the site.

The advantages of the rail system include the simplicity of the mechanism. By the way, some craftsmen even make the device with their own hands. Another plus is undoubtedly compactness. In the “wicket” mode, the canvas can be moved a short distance away to allow a person to pass, and thanks to the roller the sash does not sag. Therefore, frequent adjustment is not required for such a system, unlike swing gates.

But since the rail is located on a concrete surface, precipitation can disable the mechanism, block its operation. Therefore, it is important to periodically remove garbage and snow from the path of the roller. Keep in mind, experts recommend to mount the rail in the concrete foundation “flush”, this will minimize the damageapplied by transport on the guide.

In the cantilever gate, the rail holding the sash is attached directly to the canvas. It can be fixed in the lower, upper part of the canvas or in the middle - there is not much difference in this.The main thing is that the rail was of the required length, sufficient to hold the sash. Otherwise, you will need to install an additional electric drive on the opposite side, after which the double gates will open both to the left and to the right.

Since the guide beam is installed on the canvas, it does not depend on the cleanliness of the foundation or on the height. To balance the weight of the gate, it is necessary that the web be one and a half to two times longer than the opening, otherwise it will not be possible to establish the correct operation of the product.

Keep in mind that the rail, or as it is also called "channel", can be installed on both deaf and lattice structures. At the same time, it will be necessary to pour a solid foundation so that the supports do not vomit on the weight of the gate.

Constructions

The drive device for the suspended gates is placed in the upper part and roller trolleys are mounted in the same place. It is caused by the design feature of this variety. It follows that if a repair mechanism is required, then certain difficulties may arise. In particular, an autotower will be required to adjust the four-meter sash. In most cases, for this reason, this type of sliding gate type is not installed in the private sector.

Some manufacturers bring the adjustment of drives to the height of human growth, but, unfortunately, this only complicates the operation of the device, since additional installation of rails and pulleys is required. And any complication leads to frequent breakdown.

Vykatny gate of console type most often are equipped with the drive, the roller block and a guide in the lower part of a cloth. Quite often, mounting is practiced in the middle and less often at the top. It depends on the length of the opening, the solidity of the supports and the strength of the foundation. The arrangement of the drive can also be affected by the arrangement of the courtyard and the features of the metal frame.

Retractable rail gates are distinguished by a uniform distribution of the weight of the canvas on the supports and on the foundation. Due to this, the load on the device is reduced to zero, which means that the drive can be placed in any part of the gate. Often it is placed either in the middle or at the top. In the lower part is mounted roller base and guide rail.

Separately, I would like to emphasize that drive location will depend on the intensity of the load. If the canvas opens rarely,then it is necessary to install low-power devices for it, otherwise it will be necessary to purchase powerful, and, accordingly, expensive products.

Advantages and disadvantages

First of all I wanted to pay attention to the bottom. For example, at the suspended gate, you only need to ensure that the distance between the ground and the canvas is free. In this regard, the only obstacle can be suddenly fallen snow, and only half a meter drifts can block the work.

The maintenance of cantilever and rail versions of the gate is different, provided that the roller base is located in the lower part. In the first embodiment, periodic cleaning of the foundation from ice and snow is expected, and in the second case, the purchase of special equipment.

Therefore, in regions where there is a large amount of precipitation in winter, experts do not recommend installing rail sliding gates.

But at the same time, sliding options, moving along the rail, require less care for the drive and mechanisms in the winter season. In the second place are the sliding overhead gates, well, the most attention will have to be paid to the cantilever variety, in which the shifting device is located at the bottom. With regards to the annual preventive measures, they are the same for all varieties - 2-3 times a year.

The rail system is the most expensive in terms of the cost of the product, installation and maintenance, then the suspension system is located in an improvised rating, and the cheapest option is the cantilever gate. In the first five years, the console requires less attention and material investment.

Summing up, it can be stated that it is often the cantilever gates with the beam at the bottom or in the middle that are installed in the private sector. But keep in mind that suspended structures can last for several decades. Even until now there are workable examples, mounted 50-60 years ago.

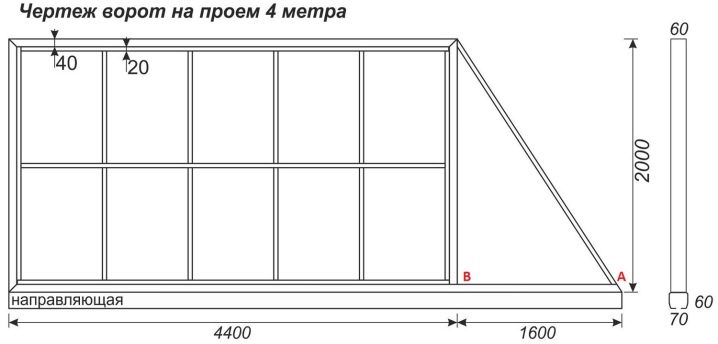

Drawings and diagrams

As an example, a variant of the console system with the location of the drive in the lower part will be considered. Depending on the location of the drive and on the opening side, the sketches may differ slightly.

Directly, the door leaf is attached to a metal frame, which is a frame made of either a metal profile or a steel pipe.The guide is welded to the metal frame. Often it is presented as a toothed rack, especially for structures with electric drive. A roller base is mounted inside the guide rail. As a rule, in the cantilever system, under the roller base are meant carriages on wheels.

The guide, moving left and right, moves the door leaf in the appropriate direction, thereby opening or closing the entrance. Since all the gravity of the sash is moved to the beam and to the roller base, a discharge roller and a catcher are mounted at the bottom of the web to minimize the load. Due to this, in the closed state, the cantilever gate does not sag. In some products, the discharge roller and the catcher are additionally installed on the opposite side, which ensures that the gate is kept open.

Fixation of the door leaf in the upper part is ensured by the catcher and the beam with carriages. In order that dirt and dust did not get in a design, the side cap is used. The supporting pillars must be assembled from a solid reinforced concrete base, brick or metal pipe.Particular attention is paid to the foundation for the lower rail, otherwise the entire structure collapses under its own weight. There is a high probability of damage to property, including someone else’s, and the risk of injuring people passing by.

The previously mentioned electric drive is easily mounted between carriages, the rack rail is fixed directly to the door leaf, a control device, photo fixers and satellite navigation are located nearby.

Calculation of materials

If old structures are to be dismantled before installing sliding gates, close attention should be paid to the support poles used previously. They can be made of metal profiles, bricks with mortgages or of reinforced concrete. remember, that deviation of supports is unacceptable, - they must stand strictly vertically, otherwise the gate leaf will touch the foundation. If the pillars have squinted, it only says one thing: they are incorrectly fixed in the ground.

By the way, it is recommended to leave the distance between the foundation and the fence as small as possible, and it is best to equip the foundation back to the supports.

If the support posts meet the requirements, then this can be saved. If you plan to install from scratch, then you need two supports.When choosing a reinforced concrete base, it is customary to erect a vertical with dimensions of 20x20 cm, for a base of a profile pipe, a product with dimensions of 60x40 cm will be suitable.

The size of the door leaf can vary significantly. This will depend on the free space along the fence, the dimensions of personal vehicles and the size of the site. In most cases, the gate leaf has dimensions equal to 4400 cm in length and 2000 cm in height.

If heavy trucks periodically enter the site, then the height of the support, the foundation and the distance must be calculated, starting from this. Keep in mind, even small trucks can destroy the foundation.

You should be aware that the width of the carriageway affects the size of the door leaf: the narrower it is, the width should be the canvas. This facilitates entry and exit into the territory.

Provided that only the movement of cars is planned to move, you only need to build on the dimensions of the car. Suppose the width of the machine is 2 meters. To this must be added the short distance necessary for unimpeded entry and exit: the distance must be at least one meter. The height of the sash in private areas rarely exceeds 2 meters.

For trucks other sizes. It is important that the height limiters were not, and the width of the passage was 4.4-5 meters. It is useful to know that the height of off-road vehicles rarely exceeds 1.5 m, and for the Gazel it is 2.5 m. KAMAZ and its analogues are considered to be the highest in height: in this case, the upper level bar should be at least 3 m

The maximum angle of arrival is usually 45 degrees. From this it follows that the distance between the support and the car should ideally not be less than 0.5 m. The length of the counterweight should be equal to 40-45% of the width of the opening. It is unacceptable that this figure was less than 33%.

It is important to take into account that the bushes and trees should not grow on the path of movement of the canvas, there should not be any interfering buildings.

Fittings

If the structure has standard dimensions (4 meters wide and 2 meters high) and is sheathed with sheets of professional flooring, then you will need to buy accessories that can support a web weight of 400 kg. Accordingly, with increasing the length of the canvas is selected reinforced fittings.

The rollers in this case fit either polymer or metal. The length of the guide beam was 6 m, and its cross section was 60x70 cm. Keep in mind that the thickness of the metal profiles should not be less than 3.5-4 mm. Four-meter metal frame must be mounted with a small margin.

Usually, experts recommend that the frame length be 4200 cm. The length of the counterweight in this case, calculated according to the formula described earlier, will be 1600 cm.

In order for the roller base to move freely along the guide, carriages will be required. To fix the position of the valves in the open and closed positions, end rollers and catchers are mounted. As previously noted, to prevent dust and debris are installed plugs.

In most cases, it is this furniture that is used. Minor changes are made when using not a console, but a roller or suspension system. To minimize lateral swing, a plateau with rollers is mounted in the upper part, and in the lower part, fixation and movement is carried out by means of a carrying trolley.

Instructions for making

Proceeding from practice, the easiest way to do it yourself is to make installation of sliding gates moving on rollers along the rail. In this case, the installation can be made of scrap materials or with the use of purchased accessories.

It should be noted that before starting work a drawing of future gates is required. It is important that the scheme is easy to read. It must be applied to all sizes, including supports and the foundation, the necessary hardware used in the work, as well as details that will depend on the location of the recoiling system. By the way, many consumers, not wanting to use mechanical methods of opening, buy electric drives before installation - this should also be reflected in the sketch.

Keep in mind, homemade videos may vary slightly from each other, but even minimal deviations can disrupt the performance of the entire system.. From this point of view, it is better not to save money and to buy the same factory videos in advance.

The gate can be built into the gate or exist separately from them. In the first case, older people and young children will have to raise their legs periodically. If this is done carelessly, you can even hesitate and injure. If the gate will be mounted separately, then it must be installed on the opposite side of the opening of the valves, so that the door leaf does not block the passage.

It is unreasonable to completely abandon the gate, since any mechanism is designed to open a certain number of times. If you use a sliding gate as a wicket quite often, then the drive will fail.

Installation of sliding gates begins with the preparation of the base. But first things first. Below is a step by step guide.

Preparatory work

It is very important that no shrubs and trees grow on the way of the gate leaf. If any plantings are planted, they will have to either be transplanted or uprooted.

The outbuildings, baths and toilets that prevent the opening of the door leaf, will have to be dismantled. It will be necessary to remove the ground from the slope so that the shutter moves freely without touching the ground.

After the terrain is cleared, the foundation will be cast. For the first time, the tools will need shovels, a tape measure, a laser range finder and a garden drill.

If there is a motor drill on hand, then the work will be done faster.

During the arrangement of the territory with suspended sliding gates, the foundation is not needed, it is enough to dig holes for the supports when planning the installation of metal pillars.For this, the location of the future holes is marked on the ground with the help of a tape measure or with the use of special tools. The distance between the supports should correspond to the dimensions specified earlier.

As a rule, the gate is installed last, which means that a fence has already been mounted on the site. A metal fishing line is tied to the extreme supports, a metal chain with a weighting agent is suspended through it. On it the evenness of the pits relative to the fence is set and checked.

Unfortunately, the design features of the motor-auger do not allow to increase it, and in order to deepen metal pipes into the ground, it is necessary to dig 1.5 meters. If heavy loads periodically pass through the passage, the height of the supports may be increased. In this way, the ground will need to be buried in metal in proportion to the protruding aboveground part.

In this case, it is easiest to dig with the use of a garden drill, because it can be increased. After passing through the fertile layer, either clay or a rocky foundation will begin.

In the first case, you need to pour water. The drill will be easier to enter into such a soil, but to pull it to the surface will become more difficult. And in the second variant it is necessary to get rid of stones.Particularly large specimens will need to be broken with a crowbar or rebar.

The diameter of the future holes must match the metal profile or steel pipe. The larger the diameter or size of the pipe, the larger the hole should be. But remember that this will require more cement-sand mixture and rubble.

The height of the holes is easiest to check either with a tape measure, while its length should be 5-10 m, or a special laser pointer. Such holes will need to do from 2 to 4 pieces, depending on the presence or absence of the gate, as well as starting from the functional features of the design.

If it is not possible to increase the garden auger or if there are difficulties with a dimple, then the metal support must be hammered with a sledge hammer. Another way out of this situation can be considered yamobur. The drilling machine will make the necessary hole in a short time.

Metal poles must be fixed in the ground. But before that, the “cushion” is laid down on the bottom - a layer of rubble. The stone in this case acts as a drainage, because thanks to this approach, the water will not stagnate and the pipe will not break.

Some experts recommend to paint metal pipes before lowering into the hole, while others construct a special "glass" of plastic pipes. Such operations are justified on the condition that the groundwater is located in relative proximity.

Brick and reinforced concrete pillars must have mortgages, often three pieces are enough. When placed at the top and bottom, it is enough to retreat 200-250 mm, the last mortgage is set at an equidistant distance from the outermost ones. Subsequently, some parts will be attached to them.

For mortgages, it is enough to take a steel sheet with dimensions of 100x100 mm, the thickness of the product should not be less than 5-6 mm.

The next stage involves the use of concrete mixers to create a cement-sand concentrate. In what proportions dilute cement and sand, usually indicated on the bags. If this information is not available, then it is enough to add 6 kg of sand to 2 kg of cement. Additionally, 12 kg of aggregate and 2 liters of water are added.

Knead the substance should be carefully, no lumps should not remain. If there is no concrete mixer available, then this procedure will have to be carried out with the help of an ordinary drill and spetsnazadki.

After that, the concrete is poured into the fossa. Remember, you need to monitor the evenness of the pillars.Drying is a long process. At high temperatures, full drying is achieved in a week, and if cemented during the cold season, up to a month.

When mounting rail sliding gates to fill the foundation between the span and along the fence on the size of the door leaf. To begin with, a trench is being dug right next to the fence. Its dimensions should be equal to 50 cm in width and 100 cm in depth. The length of the trench will be equal to twice the length of the gate leaf.

If desired, you can make a formwork. If it is for temporary use, then sheets of plywood, old boards and the remnants of chipboard are used. If reuse is planned, then you will have to purchase moisture-proof high-quality building materials.

Making shields to do on the ground, and after creating the formwork to immerse it in a trench. The boards are fixed with screws and a screwdriver, nails and a hammer can be used. Pegs are driven into the ground, a rope is being pulled along the perimeter.

At the bottom of the trench, a small layer of rubble and a sand cushion are stacked; reinforcement is required for good cement fixation.Experts recommend using valve number 10. You can weld it with your own hands, either buy a ready-made reinforcing mesh and tie it with soft wire.

For rail sliding gates on the metal frame will need to lay a guide rail. As the rail can act channel. It is important to lay it upside down and set it parallel with the ground. Subsequently, a carriage will be attached to this guide.

With regards to the foundation for the cantilever gate, it is settled in relative proximity to the support column. The length of the structure will be half the width of the span, most often 2 m is enough. The depth will depend on the location of the groundwater and on the level of soil freezing. Do not forget about laying channel.

When pouring concrete into the trench, try not to fill the channel. Keep in mind, it is necessary to tie the tie at this moment, thanks to this excess air will be released. The first days the concrete base must be checked and moistened from time to time.

It is important that during the time allowed for drying, the concrete does not crack, otherwise its strength will be minimal.

Unlike swing gates, where two drives are required, with the automation of the retractable system, one engine is purchased. But it must be recalled that in order to facilitate the work of the construction, it is permissible to use two wings and it will be necessary to equip with a second electric drive from the opposite side.

Automatic gates can be mounted by purchasing a set of necessary parts and mechanisms in a specialized shop, or, having a certain skill and experience, to make it yourself.

Automation allows you to open the gate using the remote control, without leaving the car or directly from home. There are two types of panels with floating and fixed code.

In the first case, it is practically impossible for attackers to pick up a combination of numbers. For a fixed code, room hackers can read a combination. The probability of accidental opening with a coincidence signal is also great. In other words, if a passing man pushed the car alarm button, or someone in the next house turned on the chandelier with a remote control, the cipher could coincide and the gate would open. Therefore, you need to think carefully before buying an electrical system, which one is better to take, but it is not expedient to save money on this issue.

Still, the main part is the engine.It happens with a chain signal and with a roller. The engine must be selected taking into account the specifics of the site.: if a three-phase meter is installed on the territory, then it is desirable to purchase a three-phase motor.

It is very important that its windings have a star connection. Due to this, it will be possible to eliminate a number of problems arising during the operation of the drive. The device will work with maximum power, and therefore with good efficiency.

Alternatively, a single phase motor may be used. At the same time it is important that it be of condenser type. Its main feature is considered low performance, including when you start the mechanism. Power of the unit should not be below 1-2.5 kW. It will depend on the weight of the door leaf.

Indicator speed - from 500 to 1000 revolutions per minute. Low indicators allow you to get rid of a significant load, including on the base of the drive shaft.

When using single-stage gearboxes, a drive wheel is required. It should not make more than 100 rotations per minute. From this it follows that the rate of incoming torque should correspond to the rate of rotation of the engine.

It is acceptable to use cheap analogues, but keep in mind that the kinematic scheme should not have bad connections. An alternative to the engine can be a working motor from a washing machine. Such products are often thrown into a landfill, which means that the engine can be obtained completely free of charge.

Before connecting the motor, it will be necessary to determine where the ends of the winding are located. This will help the device called a multimeter. Large indicators of resistance will be at the start-type winding.

A rigid or semi-rigid coupling is necessary for fixing the gearbox shaft with the motor. In the first case, the body resembles a sleeve, the connection is due to various holes and special grooves. In a semi-rigid coupling, two flanges and rubber elements provide the connection.

Replacing the gearbox can serve as a belt type transmission. The belt drive operates on bearings that are located on an independent shaft.

Keep in mind, the shaft must be set strictly in the center, otherwise the transmission will not work properly. Belt drive is very difficult to assemble.

Installation

First of all, the metal frame is made, which should completely close the opening. It is made of a shaped pipe of the required cross section, which depends on the weight of the future structure. In order to do this work yourself, you need an angle grinder, which is popularly called "grinder", and a welding machine.

The metal frame can be equipped with a wicket, but at the same time it is not forbidden to make it separately. Do not forget to mount constipation. It is worth noting that for a separate gate, additional support will be required.

Some people believe that it is correct to install automation at the time of installation of the sliding gate, and not after some time, since it is possible to correct some errors on the spot.

If the electric motor is installed on the already working gate, some elements will have to be dismantled, and this leads to additional expenses.

When automatic equipment is made from improvised means, a bicycle star is attached to the gear shaft. If such a detail is not at hand, an asterisk from the motorcycle will do. Subsequently, the corresponding circuit is installed on this element.Fasten it over the entire portal sash strictly in the horizontal plane. When the asterisk rotates to one of the sides, the gate either opens or closes.

The engine is attached to a metal frame, which is made of steel. The frame must be installed on a dry foundation and firmly fixed. The stronger the connection, the longer the entire structure will last.

When choosing a gearbox, it is necessary to pay attention to the height of rotation along the axis. In the gear wheel axial tightening is carried out by the shoulder. The height of the shoulder depends on the fixation of the wheel in the direction of the axis. Therefore, there is a high probability that it will be necessary to construct a two-level base in order to fit a gearbox with a motor.

Bolts and special nuts are used to connect the gearbox to the motor. The base under them should be flat and made of durable material. In order to make it easy to adjust the position of the engine, small holes are made under the support.

An additional rail is installed on the portal door, at a height of 50 cm to 80 cm from the base. To this beam is attached gear rack.Its ends are protected by plugs, so that dust and debris will not be clogged inside. Guide must be welded to the gate quality.

In order for the chain not to stretch, the product is equipped with a special roller with a rigid spring. Some people install a part with eyelets on the last link of the chain - this ensures tightening of the chain at the time of opening and closing.

Not only the suspended gates differ in the location of the rollers in the upper part of the structure. Set these elements at the top will be required for rail gates. The upper roller ensures the fixation of the sash, due to which the door leaf will withstand the wind load.

Pinch rollers are attached to the bottom of the sash, after which they easily move on the rail. It is important when buying a roller base to pay attention to steel products with sealed bearings. They must withstand the weight of the gate.

Also do not forget about the return rolls, which are mounted on the opposite side.

It is important to check the operation of the structure before connecting the automation. When opening or closing the door leaf, nothing should interfere, and the gate should not bend over its own weight.Do not forget about the installation of catchers that will allow the gate to close without changing the trajectory of movement.

To connect the elements of automation, to fix the channel with the guide, as well as to install the rack with teeth, welding is used. The drive mounted on the channel is bolted. Holes on the channel must be pre-drilled. For this fit simple drill bits for metal.

Next, install end switches. They are magnetic or mechanical. The first option works in bad weather. The magnet is mounted directly on the rack. In principle, the second option focuses on the spring.

All settings are made according to the instructions from the manufacturer. The design of the sliding gate additionally includes not only an audible alarm, but also an indicator lamp and several photocells.

Photographing allows the device not to close the gate, if there are foreign objects on the way, including cars or animals. This is very important if the family has small children. Unfortunately, without photocells there is a high probability of injury.

The satellite system allows you to open the sliding gate in advance, approaching the house for a few meters, you can open not only the gate leaf, but also the tilting mechanism in the garage. Due to this, time is significantly saved, because you do not need to leave the car.

Decor

Forged sliding gates are considered strong, durable and beautiful. They are perfectly combined with brick or stone fences and supports, as well as with wooden inserts.

At the same time, they can be both open and closed. Metal patterns noticeably decorate the front side of the fence. They can be made according to special sketches, thereby emphasizing the personality and tastes of the owner. But at the same time, expensive gates can attract intruders, because they unequivocally hint at the financial situation of the property owner.

In order to reduce the cost of products forged gates can be made on a standard drawing. It often uses direct hire technology. Any decorations and monograms are not provided, only the classic design.

Since the gate is installed on the street, very it is important that they are processed at the production stage. For this, cold galvanizing is used. Welds are cleaned, treated with primer and painted. Special paint of any color is used as a paint coating.

Fans of wooden constructions fix treated wood to the metal frame. From the point of view of weighting the structure, this is not entirely justified, since it can greatly affect the support pillars and other elements.

Sheets of a professional flooring and evroshtaketnik weigh less. They are attached to the metal frame with special hardware and a screwdriver. Acceptable use zaklepochnik. Rivets press metal sheets with greater efficiency than self-tapping screws. Self-tapping screws can be twisted, and rivets dismantle problematic.

Sandwich panels are widely used in the West. They are distinguished by their low weight, ease of installation and reasonable price. In stores there are products of brown or white.

Do not forget about airbrushing. Drawing makes a professional artist with the help of special equipment. The cost of his work, of course, depends on the complexity of the picture.

In order to save, you can paste special typographical paintings. Volumetric 3D stickers highlight and, at the same time, mask the gate.

Operation Tips

In order for the sliding gates to serve as long as possible, you should only pass through a free span. From this it follows that there should be no objects interfering with the passage, including the entry of foreign elements into the structure is unacceptable.

It is important to pay attention to the sound that occurs when opening or closing the sash. This may indicate the impending deterioration of the product, which means that timely prevention and adjustment will be required.

Adjustment involves the periodic lubrication of the moving mechanisms of the structure. In order for metal parts to not rust, it is necessary to treat them once a trimester with a special tool - WD-40 or, as the people call it, “waddish”.

Lubrication and inspection of the engine produced every year. For this operation, it is desirable to call a specially trained person, otherwise the responsibility for the result lies on the shoulders of the owner.

In winter, you will need to monitor the cleanliness of the rail and guides.The icing of the roller base and other parts affecting the operation of the sliding gate is unacceptable. Periodically you need to tighten the bolts and screws.

The cable system must be protected from precipitation. Do not forget to check its performance every 3-4 monthsso that the sliding door can be opened without electricity. Otherwise, to get to the territory of the site with no blackout.

To learn how to make a sliding door with your own hands, see the next video.