Accessories for sliding gates: rules of choice

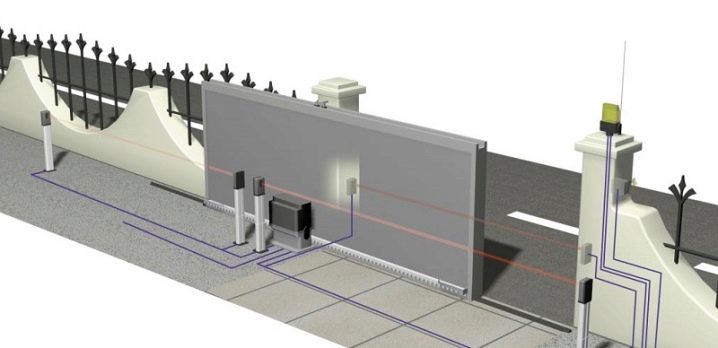

Modern modifications of the doors are equipped with various types of electric drives, which simplifies their movement. One of the most practical and common designs are rolling systems. The door leaf moves along special guides, where rollers are installed to soften friction.

The work of such structures just depends on the small mechanisms by which the whole procedure of movement is carried out.

Proper selection of components will extend the life of the gate for the maximum possible time.

What is included?

Sliding gates are practical because the sash moves parallel to the main fence, without taking up space in front of the entrance. Therefore, they are used for arranging walk-throughs at industrial or business enterprises.

Today there are several types of similar structures that differ in technical nuances. But, regardless of this, such a system consists of several main components:

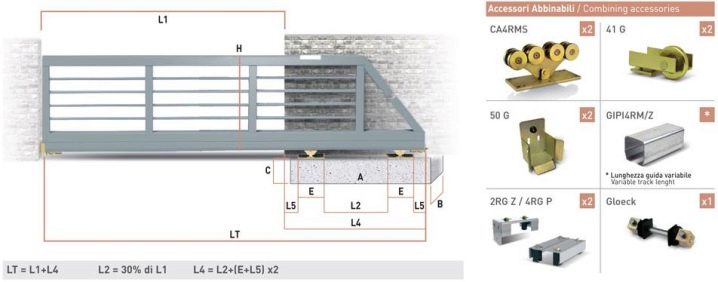

- Mortgage. It is an ordinary metal channel, which is located in the soil. To give strength to it welded reinforcing rods. Outwardly, this whole structure resembles the letter “P”, which is concreted in a trench. The length of such a system is half the size of the opening. Console and suspended gates are not equipped with such elements.

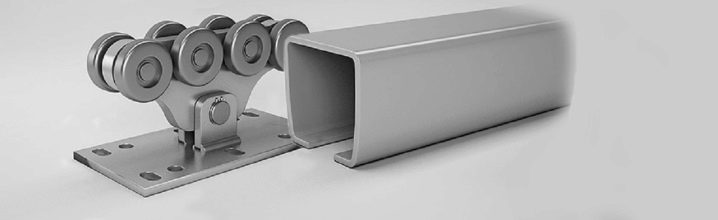

- Bearing profile. The element is a kind of guide, as the rollers move inside it. Externally, the product resembles an ordinary channel, but has curved ends. This prevents the rollers from popping out of the groove. Attach the profile to the bottom of the canvas. The material is subject to high loads, so the element is made from high-quality and durable steel.

- Roller carriage. The design consists of several support rollers, which are attached to the channel. These products allow you to move the canvas along a straight line. There are several types of carriages, as they are calculated for a specific web weight.The main material is metal, but some manufacturers use special plastic in their manufacture.

- Support rollers. The main task of the rollers is to support the web in an upright position. They act as a kind of guides, which are mounted above the sash. Depending on a design, the system can be equipped with two or four basic rollers. To reduce pressure and minimize friction, they are made of plastic.

- Catchers. They are divided into upper and lower systems. The first type is intended to limit the movement of the web perpendicular to its main plane. Simply, with the help of upper catchers, the structure is protected from strong wind in the closed position. Bottom designs are used to support the web. When moving, it hits the trap from above, which partially absorbs the load.

- Roll roller. It is attached to the lower corner of the canvas in such a way that it falls on the lower trap. They make products from various materials, but in most cases plastic is used for this.

- Stubs These elements are used to close the voids of the guide tube. This approach eliminates the ingress of water, debris or snow inside. In turn, such protection extends the service life of the system several times, and also does not allow the formation of ice on moving rollers.

- Cloth gate. Almost always, the sash is made of durable metal pipes that can withstand the maximum load and weight.

Theoretically, you can use almost any type of canvas, the main thing is to choose the right all the other components.

Today, sliding gates are often completed with automatic systems of movement. Automation is not a required attribute, but it is almost always present. This system consists of several basic devices:

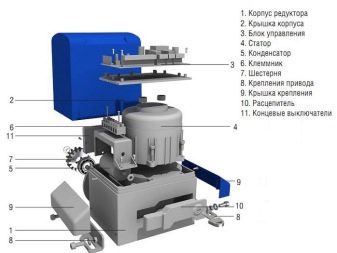

- Electric motor This mechanism is the main, because it sets in motion the canvas. Install it on a concrete base, as well as supplement with special protective covers to prevent the ingress of moisture and debris. Some models can be controlled remotely, with many advantages.allowing almost completely eliminate the participation of man in the gate.

- Limit switches. The main task of such mechanisms is to control the operation of the electric motor. Technically, these are peculiar relays that cut off the power supply when the gate reaches the end point.

- Protective block. The system consists of a set of electrical components that are interconnected by various connections. The main task is to control the operation of the electric motor, as well as to prevent its overload during operation.

Please note that not all kits necessarily include all devices and mechanisms. Today, many manufacturers produce modifications that consist of a specific set of elements.

Fittings

The quality of the sliding gates depends on the set of fittings used. Today it is possible to install several types of systems on such structures, but not all of them will be able to ensure long and reliable operation. When choosing fittings, there are several main factors to consider:

- The weight of the canvas. Sash today can be made independently or at the factory.This leads to the fact that the mass of the gate can vary in a very wide range. This factor affects the operation of the rollers and gears.

To ensure high-quality operation is possible only with the help of metal support rollers, which perceive the main load. The greater the weight of the web, the more desirable it is to use supports of this type.

- Wind load. For places with strong winds, it is desirable to use several upper suspension rollers. They should take almost the entire load on themselves, not allowing the gate to swing. Therefore, preference should be given to high-quality metal hangers.

- Quality guide. After installation, this element takes the main load, so it must be durable. Quality products should have a uniform cross-section, and also not have distortions of the frame. The presence of chips or irregularities can lead to blocking of the rollers during movement. High-quality support beams are made only of structural steel, and their thickness is selected, depending on the weight of the canvas.

Experts recommend buying beams with a weight margin,which should exceed the real mass of the gate by 1.5 times.

Automation

The choice of electric drive depends on many factors, among which there are several main ones:

- Engine power. This characteristic is directly dependent on the weight of the canvas. But here one should not be too zealous, since there is no need to acquire powerful devices capable of moving a canvas weighing 1 ton, if the gate does not exceed 200 kg. Power reserve should be small so that the system can cope with the load.

- Star material. Today, manufacturers produce automatics made of metal or special plastic. It is impossible to say which option is better. The polymer is not temperature sensitive and requires a minimum amount of lubricant. But the metal, in turn, serves much longer, since it is highly durable. But for a system based on metal elements to work well, it is important to precisely install and configure it.

- Intensity of operation. This indicator takes into account the frequency of opening the canvas for a certain period of time. For example, there are structures that can be moved no more than 18-20 times for an hour.If the gate is installed at a checkpoint, then they should be able to move almost every minute without interruption. You can find out this value in the instructions for a specific model of automation.

- Functional. High-quality automation should set in motion the gate at the beginning of the cycle with a slight delay, as well as provide the opportunity to open the canvas to half.

If you want even more comfort, then preference should be given to models that are equipped with an automatic closing function and several touch sensors.

- Voltage level. Today there are modifications of motors operating from 220 V or 24 V. The second type of drives can operate from a conventional battery, but is not always able to provide the necessary power. Therefore, industrial models are complemented by engines that connect to the normal network of 220 V.

Manufacturers

The quality of sliding gates depends on the reliability of all components. Therefore, it is important to pay attention to the rating of manufacturers of such systems.

Overview

Among all this diversity, there are several popular brands of accessories:

- Roltek. The company has long been engaged in the production of automation for sliding gates, as well as all their constituent elements. Among the advantages are the use of special lubricants that allow you to comfortably operate the rollers, regardless of the ambient temperature. All guides are made of corrosion-resistant steel, which tolerates almost any weight of the sash. The manufacturer guarantees the system for 5 years.

- Came. The company puts on the market both industrial and household models that are suitable for solving any modern problems. Among the positive features are the best price / quality ratio, as well as ease of installation. The quality of the material is one of the best in Europe, but the products differ by a very low price.

- Alutech. Products of the Belarusian company, which has an optimal price-quality ratio. Components can be supplemented with flaps, the weight of which does not exceed 800 kg. In the manufacture of accessories specialists use high-quality galvanized steel.

Reviews

There is no perfect product, since everything also depends on the operating conditions and proper installation. According to customer reviews, some models could not withstand constant loads.Especially it concerns products from polymeric materials. Quite good feedback was received by the products of the company Came, which performed well in various climatic conditions.

Many argue that after improper installation, the asterisks quickly failed, as they were simply erased when moving. The solution is high-quality setting and timely lubrication of all rubbing units.

Recommendations

To get reliable and durable sliding gates, should be guided. a few simple rules:

- Buy mechanisms that are optimized for each other in all respects.

- Give preference only to products of well-known manufacturers, since this is the key to durable work.

- Installation of gates and automation should be carried out only by experienced professionals. It is advisable to trust this representatives of the store where you purchased the product.

The selection of components for sliding gates is a complex operation that is best carried out after consultation with an experienced installer. He will be able to analyze all the shortcomings of the selected model and choose the best option.

Review the accessories for sliding gates in the next video.