Repair of sliding gates

Retractable gates belong to the most functional and justified, from an economic point of view, types of structures, which determines their high popularity. The service life of sliding gates is practically unlimited, since there are no fragile and easily breaking elements in their design. Their device is simple and practical rationality, so it seems that there should be no damage.

Bearing structural elements of such gates and their canvas are made of materials resistant to wear, and the need to repair automatic sliding gates is extremely rare. The automatic drive of the doors of such gates is also not difficult. However electric drive and automatics controlling them may become their vulnerable point.

Main malfunctions

In the normal cycle, the sliding gate works as follows:

- According to the signal sent from the control device, the motor of the portal drive causes the gear gear, which interacts with the gear rack, to rotate. Due to the latter, the torque from the gear is converted to the movement of this rail. It is in rigid connection with the door leaf.

- After this shutter reaches its extreme position, limit switches are activated. They give the signal to turn off the motor.

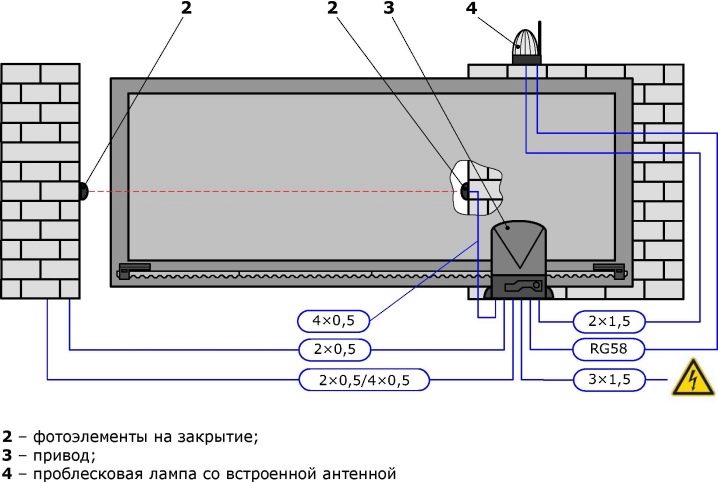

- Closing the gate has a reverse order, but this is triggered by another protective system. It consists of photocells that do not allow the gate to close when an obstacle appears in their doorway in the form of a person, a pet, or a passing car.

All the action of gate automatics is aimed at creating conditions for their safe functioning and excluding the possibility of people getting injured and causing damage to motor vehicles.

therefore in the event of malfunctioning of the signal sensors, the gate stops. The false positives in the protection system also contribute to this. The gate can not open at all, move in jerks, do not open or do not close until the end.

Damage options:

- If the gate refuses to open at all, then it happens for two reasons. They are the presence of failures in the control systemwhen there is no transmission or reception of signals and failures in the locking sensor. The drive of the gate is blocked when the system does not receive the “locked” signal when the gate leaf is closed. In this case, make sure that the locking sensor is in good condition and replace it in case of a malfunction.

- Another malfunction may be breakdown of control sensor, which is detected by the absence of a click from the relay inside this sensor when a signal is received from the charm. In other words, the sensor is faulty if there is no such click.

- Sliding gates may not open or their sash may stop until full opening due to false action limit switches. This applies particularly to mechanical sensors. They tend to wear out over time. Such sensors are sensitive to atmospheric moisture, precipitation, the appearance of ice and similar external factors. In this situation, repair manipulations for such gates consist in the replacement of failed limit switches.The best solution here is to install magnetic sensors that are most resistant to weathering.

- Most of the automatic elements of the sliding-type gate electronics are located under the open sky. They have good protection, but nevertheless, if there is abundant precipitation and significant temperature drops, moisture penetration and condensation inside such elements. Characteristic signs of failures in the functioning of the gate electronics in such cases are jerks, and the occurrence of stops at the time of movement of the door leaf or its movement in only one direction, as well as unstable operation of the electric motor.

Defects in the gate electronics are detected by a multimeter and are eliminated, depending on the nature of these faults. Basically it comes down to the restoration of broken contacts, repair or replacement of damaged elements.

- Sudden stop of the door leaf when closing can occur as a result of false signal from photocells. The most common cause of such a problem is their contamination.In this case, the need for repair of the gate does not arise. It is enough just to wash these solar cells with alcohol. For the purpose of prophylaxis, it is recommended to carry out such a procedure about once every three months.

- In adjustable automated systems, their settings may be reset due to mains voltage drops and for some other reason. In this case, the user settings may change to the state of the manual mode or “default”. As a result, a new setting of the gate electronics system is required.

- In addition to the above reasons of electrical nature, failures in the operation of sliding gates are purely mechanical. Usually they are due to the presence of distortions in their supporting structure. Such imbalances may occur initially with violations in the process of installation of the door, and may appear during their operation due to wear over time of steel structures or under the influence of moisture and temperature differences. The latter case, however, may also be the result of errors in the assembly process, for example, with insufficient foundation strength.All this causes jerks, vibrations and the emergence of extraneous noise. The door doesn’t accurately fall into the trap when closing. There is a need for excessive efforts to release the sash from this trap at the time of opening the gate.

Moreover, such a misalignment in the mechanical part of the structure can lead to excessive loads on the drive shaft, which leads to the engine blocking by the protection system. Therefore, it is necessary to eliminate such structural distortions to create the conditions for the movement of the gate leaf especially horizontally.

- No less common problem can be called violation of the transmission of torque from the gear gear to the rack. This assembly experiences particularly severe mechanical loads, which cause it to wear out over time.

- Its main malfunctions are distortions in the area of pairing gear gear and rack. Solving the problem is to adjust the position of this gear relative to the rack. If there is a significant change in the geometry of this rail, the areas in which the deflections have arisen or the entire rail must be replaced.

- The next point is misalignment, due to the skewing of the door leaf. Repair here consists in returning such a sash to a geometrically correct position. It happens that for this purpose it is enough several times to move the sash back and forth perpendicular to the plane of its movement. But in the presence of deformations in the bearing structural elements, you should first deal with their elimination.

- This can also be counted wear of teeth on the rail and gear gear. Such a problem can be eliminated only by replacing the entire assembly, and its prevention is the systematic periodic maintenance of automatic gates.

- If there is a discrepancy between the drive power and the mass of the door flaps or skews in the supporting structural elements that persist for a long time, drive failure working in conditions of constant overload, there is a need to acquire a new one. To avoid this, it is necessary from the very first moment to monitor compliance with the installation technology of the gate, select the optimum power of the electric motor for a given mass and carry out continuous monitoring of the state of the supporting structural elements.

Preventative maintenance

This should include measures for keeping the gate mechanism clean for the entire duration of its operation. Special attention is required for this moving parts, which include roller bearings of the lower beam, fishing rollers and upper rubberized rollers.

Recommendations:

- If extraneous sounds such as creaking, gnashing and the like appear, it is necessary to show increased attention, and all moving parts should be regularly lubricated.

- Photocell lenses should be wiped regularly with a soft cloth. Any foreign objects should be immediately removed from the photocell.

- It is necessary to clean the toothed rack and gear of the gearbox in a timely manner from dirt and ice with snow in winter and to observe their technical condition.

- It is necessary to control the shifts of the foundation, which, even with its proper pouring, can move somewhat in the spring. As a result of such a move, the door leaf will start to hit the lower catcher or hang over it.

- Balancing and eliminating imbalances can best be performed by qualified specialists from a service company.

As for the attempt to repair the sliding gates with their own hands, then for the overwhelming majority of the owners of these systems such manipulations are unlikely to be able to because of their very high technical complexity.

It is best to entrust such work to specialists, since the companies that manufacture and install such gates are also engaged in their repair and maintenance.

About what to do if the recoil roller broke at the trot, see below.