Types and features of sliding gates

Sliding gates are a great alternative to traditional swing structures. They are distinguished by a more thoughtful and complex structure, which can be difficult to make with own hands. It is convenient to use such gates, and they look stylish and modern. Today we will talk about the varieties of such structures and their distinctive characteristics.

Advantages and disadvantages

Currently, high-tech sliding gates are used throughout the world. The demand for such products is due to their rich appearance, durability and ease of use. According to experts, the sliding mechanisms are far from being the most complex, so it is quite possible to make them with your own hands, but not all people decide on this.

Many are frightened by the risk of creating poor-quality and unreliable structures that will quickly fail.In such cases, of course, should contact the professionals.

Today, sliding systems are not as expensive as before. They have ceased to be a wonder, so many consumers can afford them. It is possible to use automatic designs in the conditions of private and country houses. Most owners of such gates note their reliability and ease of use.

As a rule, modern sliding systems are a large rectangular frame, decorated with sandwich panels. The frame is most often made of aluminum. Also, for its manufacture is often used more durable galvanized steel.

In the production process, the profile is covered with special protective mixtures that make the frame resistant to corrosion. Durable and durable metal is also used in the creation of the power frame, which is a bearing part. Thanks to the use of such materials, we can safely talk about the reliability and long service life of such gates. As a rule, their frames are concreted, therefore even a very strong wind does not loosen them and they hold very tightly.

It is worth noting that modern sliding structures can be supplemented with a wicket or a small window.

Often, the owners order detached wickets, which are made from the same raw materials as the gate. Outwardly, such compositions look attractive and thoughtful.

Advantages and disadvantages

Retractable gates, like any other structures, have their strengths and weaknesses, which you need to know about if you plan to install such systems.

Sliding systems absolutely do not interfere with the entry and exit of cars in a small area, since they do not take up extra space at the time of opening / closing, as simple swing structures. In such products there are special lower anchorage, allowing to equip such a gate, even in harsh climatic conditions.

Retractable gates can be supplemented with various finishing materials. For example, it can be a neat vertical crate, neat sheeting, spectacular art forging and many other elements. Modern consumers face a rich selection of designs.It can be traditional options from a sandwich panels or a professional leaf of different flowers.

The main advantage of which experts also speak is that in the sliding gates, the loops sagging is excluded. Such problems often arise in swing systems. All automation and mechanisms in high-tech structures are designed for continuous operation.

Consumers can independently choose one or another automation for their sliding gates.

If all the installation work was done correctly, then the course of such gates will be soft and smooth, and even a fragile girl can cope with them. Many people were pleased with the fact that in winter time it is not necessary to clean the snow in the opening of the sliding gates.

Despite such an impressive list of advantages, modern sliding doors have some weak points:

- To make the whole structure more reliable and stable, the pillars and gates must be concreted.

- The rollback of such structures requires free space, so that you do not have to lock the gate every time.

- Experts recommend paying particular attention to the rolling systems of sliding gates. They should always be in good condition.They must be cleaned of any dirt, street dust, leaves and snow.

- It should be noted that these designs are more expensive than the classical swing (by 10-20%).

To fix the cantilever part and the drive in automatic versions, it is necessary to prepare an additional foundation, and it is not recommended to save on materials in this case.

Kinds

There are several types of sliding gates. Each of them has its own characteristics, advantages and disadvantages, which should be discussed in detail.

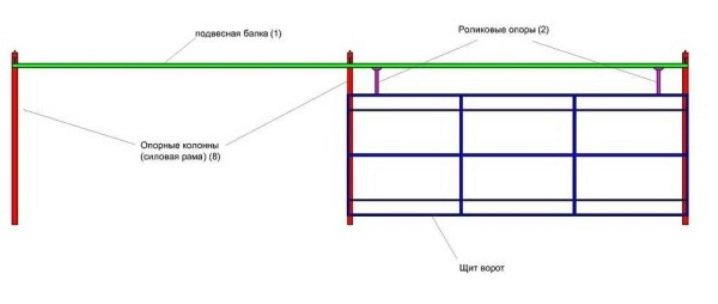

Suspended

Most often, such systems are installed at the entrance to the territory of various enterprises, factories, warehouses and hangars. In such structures there is a strong guide, which is fixed on the upper beam floor. The flaps of these systems are suspended and moved using special roller carts. As for the lower part of the canvas, then there are no supports in it.

The advantages of the suspended gate include:

- Increased resistance to sudden gusts of wind.

- Long service life.

- Durability and reliability of the structure as a whole. According to experts, such products, installed 50 years ago and more, still serve regularly and do not bring trouble.

- Since there are no lower supports in such structures, they are not afraid of severe weather conditions.

- Such designs are both mechanical and automatic.

- As a rule, gates with top hanger are able to resist opening and breaking.

The disadvantages of such systems include:

- The increased metal consumption of such products does not in the best way affect their final cost.

- Limited transport capacity due to the top position of the top rail.

Rail

Rail gates have a simple design. In them the flap moves along the rail, located in the ground along the line of the opening. Rollers welded in the lower part play the role of a web support.

Rail designs on their own to make very simple. That is why they are found in the private sector most often. In addition to the simple structure, rail systems have the following advantages:

- They can be installed even in large openings with a size of up to 6 m. In such constructions, the sash will not sag.

- Such models are not bulky dimensions. For example, at the time of opening the sash will take up as much space as the opening allows.

- Rail constructions are impact resistant and completely safe.

In their manufacture, experts recommend the use of a reliable and durable frame, as well as a heavy fabric lining that will be resistant to mechanical damage.

As for the drawbacks of roller systems, they include the need to periodically clean the monorail from dirt, street sand, debris (even the smallest) and any other things that prevent smooth movement of the sash.

Also, the owners of these structures should take into account the fact that after rains or melting snow the water in the rail may harden. The ice will block the work of the structure and will not allow the leaf to move along the guide. Such an unpleasant problem most often occurs in the winter season in conditions of sharp temperature jumps.

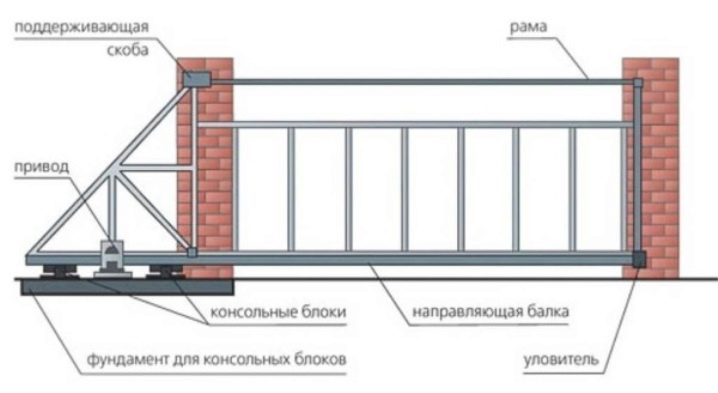

Cantilever

Cantilever are called automatic sliding gates. They are suitable for arranging both production and simple private areas. If we consider such options in terms of value for money, then they have no competitors and are ahead of other systems listed above.

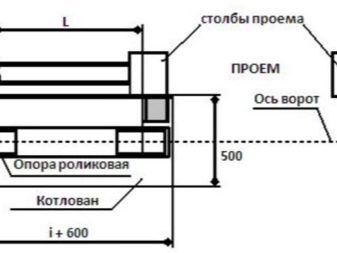

At the base of these structures there is a special console - channel. It ensures that the door leaf is held open or closed. To balance the weight of the canvas, the length of the guide beam is usually 1.5 times the width of the opening.

The advantages of console structures include the following indicators:

- The sash in such systems does not touch the ground, because of which its movement does not depend on weather conditions. As a rule, the distance from the web to the ground is at least 10 cm.

- The canvas in console versions moves as smoothly and easily as possible. Of course, this largely depends on the correct selection, and on the competent installation of all the constituent elements.

- As for the height of arrival, there are no restrictions.

- The rollers in these systems are located in the inner part of the welded beam. Thanks to this arrangement, roller carts do not fall in the form of mud, snow or water. This feature ensures a long service life of these parts.

- The canvas in such systems is very tight to the fence, which is a real salvation from the sophisticated eyes of neighbors and passers-by.

- The electric drive in console versions is easy to install.

Fireproof

Otherwise such constructions are called fire resistant. They are a thoroughly thought-out system that serves to fill openings in special fire protection fences. During a fire, such models prevent the spread of fire, and also protect the space not only from destructive flames, but also from smoke and high temperatures.

Similar cloths consist of the following elements:

- Sturdy and robust frame.

- Sash with a special lining consisting of two sheets of steel and a special filler.

- Guide rails.

- The constituent elements of the console system.

Such designs are also automated, mechanical and equipped with a counterweight magnet. At the moment, products with automatics are among the most sought-after, as it is easy to work with them and they are no less reliable than the “manual” options.

Telescopic

Telescopic retractable models are more rigid and reliable. The speed of their opening is several times higher than that of simple options.Telescopic structures are often made fireproof.

The positive qualities of these products include:

- Stability of work.

- The presence of four points of support.

- Small sizes.

- Frames in telescopic systems are stronger and more resistant to loads and bends.

Varieties of canvases

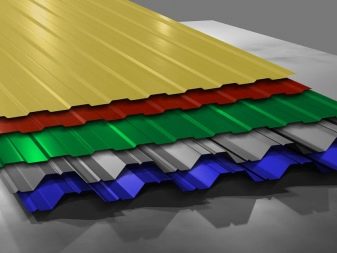

Sliding designs are equipped with various shutters. This may be closed solid options, trimmed with various materials. Most often, sandwich panels are used for their casing, but other coatings can be used, such as sheeting.

Also quite often aristocratic lattice canvases. As a rule, such products consist of an aluminum profile.

If you want to decorate the area with a non-trivial and attractive fence, then you should refer to the design, equipped with a combined sash.

Such a model consists of both a closed collar and a lattice overlay. They may contrast with each other or slightly different shades.

Material

Modern sliding structures (mechanical and electrical) are made of different materials.For the manufacture of the frame of such models most often used strong profile tube, galvanized steel parts or solid wood. Many people try not to use wooden parts, as they consider them not durable enough, but these elements also last a long time and do not cause serious problems during their work.

As for the internal filling of the leaf, the following popular materials are used for this:

- Wall sheets profiled. They are lightweight and easy to handle. In addition, such raw materials are quite strong and durable, and also looks aesthetically pleasing.

- Metal sheets. Such materials have a more impressive weight, so working with them is not so easy. But they differ in the increased durability and long service life.

- Tree. This material is demanding in terms of care. It is necessary from time to time to process it with special protective impregnations, otherwise the material will crack, dry out and acquire wood parasites. Indisputable plus of such finishing is a presentable and beautiful appearance.

- Forging.Forged parts can easily turn a simple sliding gate into a work of art. The main disadvantage of such products is their high price. Not every consumer can afford such a “pleasure”.

Dimensions

The main component of the entire sliding mechanism is the console equipment. Its cost is often 30-40% of the value of the whole structure. As a rule, these parts are delivered complete with beams of 6 m each. If you wish to order parts with a width of 4 m and a “tail” of 1.5–2 m, then the beam will correspond to these parameters.

In case the construction width indicator exceeds 4 m, then you will have to order special and more expensive equipment. That is why you should be as careful and balanced as possible when choosing the dimensions of the structure being purchased.

The most common systems, the dimensions of which are:

- 3x2 m

- 4x2 m

- 4,2x2 m

- 4x2.5 m

Colors

In any sliding gates there are metal elements that are recommended to be painted so that their appearance is more accurate and aesthetic, and also no signs of corrosion are formed. To do this, you need to degrease the surfaces that you will paint.They need to be cleaned and treated with a special grinding disc mounted on the grinder.

Some areas, for example, covered with a protective agent, you can simply wipe with acetone. After these steps, you should proceed to the primer base. It is applied neatly and evenly over the entire surface. In addition, the primer must be applied so that there are no ugly drops or stains.

If all the preparatory work is done correctly, the paint will fall evenly and will look beautiful.

Sliding gates painted in the following colors look especially aesthetically pleasing and presentable:

- Brown.

- Green.

- Red.

- Burgundy

- Gray.

- Blue.

- The black.

Extremely rarely meet the sliding gates in white. Such structures remain attractive for a short time, as they are easily exposed to various contaminants. They will have to be cleaned regularly.

As for the black variants, they can be used far from always. Such options look gloomy, so they are recommended to use against the brighter facade of the house or the fence. Otherwise, the appearance of the local area will be too inhospitable.

Design and mechanism

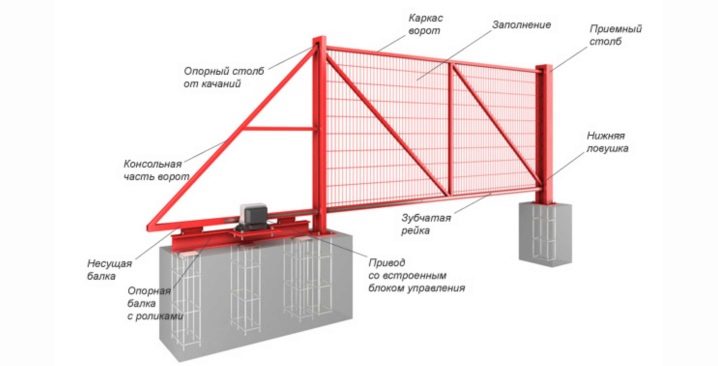

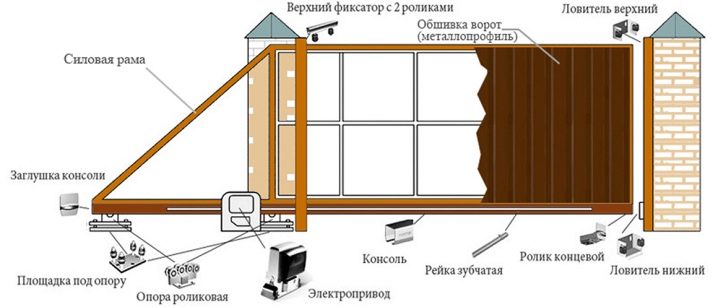

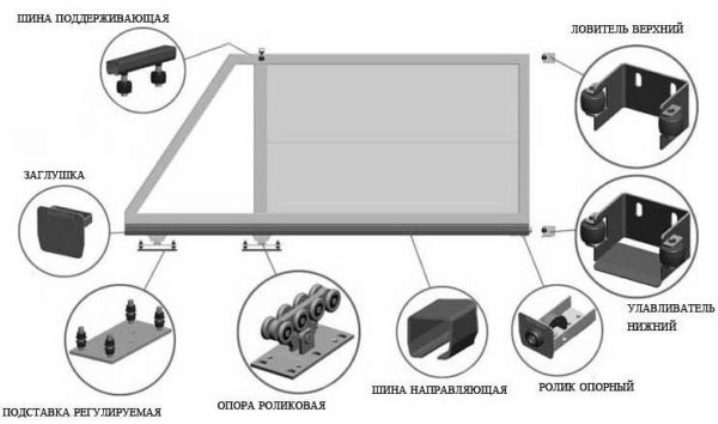

All designs of sliding systems are fairly simple. They consist of the following essential elements:

- Shield

- Frame hidden in concrete.

- Guide and roller systems.

- Electric drive

As a rule, in the upper half of the sliding gate design there are special frames, and on the opposite side - the upper and lower catchers (the location of these parts may vary depending on the model). As for the rollers, they are located in similar copies at the same distance in two places of the whole structure.

The simple mechanism needed to move the sash is represented by an electric drive. You can control it using a special button or remote control. Automatic options are more convenient and easy to use, as this significantly simplifies the process of opening and closing the web during bad weather.

Let us consider in detail what components are present in the automatic mechanisms of modern sliding gates:

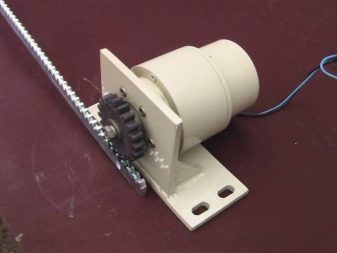

- Engine. Thanks to this detail, the actuator opens and closes the sash.For lightweight and more impressive structures by weight, a different drive power is provided, which will seamlessly withstand the burden placed on it. That is why, when purchasing a motor for sliding gates, it is necessary to consult on the topic of power with a professional.

- Gearbox. Professionals advise buying special worm variants. They will provide the gate with a long and trouble-free service life. When choosing this part, be sure to pay attention to its body. It should be made of high-quality aluminum alloy. With such a detail, the gate mechanism will be more durable and wear-resistant.

- Electrical limit switches. In this case, it is better to give preference to magnetic parts - they perform their basic functions in almost any climatic conditions.

- Control block. This constituent element has no complicated and cunning functions, but standard operations, which make it easy to use the mechanism, are handled without problems.

As for the necessary hardware, it includes the following important details:

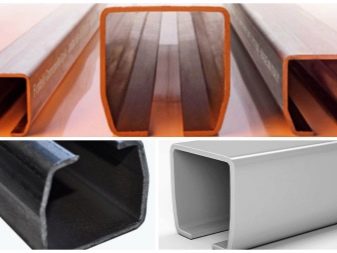

- Guide profile. Without this part, it is not possible to move the sash to open or close.

- Rack. Experts recommend to buy exclusively galvanized metal slats for sliding gates. They are installed along the collar, but at the same time there must be a distance of 1-1.5 mm between the gear wheel and the rack.

- Roller carriage. As a rule, two pieces are included in the set. Such elements are made of reliable metal or polymeric materials.

- Support rollers. These elements are set at the top. They are necessary in order to prevent the swing of the gate.

- Catcher This part is needed for reliable lower fixation of the knurled end roller. With the catcher, the sash is fixed and unloaded.

- Flap catchers in the upper section.

- End roller This element is installed together with the guide and the metal cap.

- Rubber plugs. Such parts protect the guide beam from adverse weather conditions, pollution and other similar problems.

- Photo cells (in a different way - sensors). These items are necessary to ensure the safe operation of the entire retractable system. It is they who do not allow the doors to close at the moment when motor transport or any other object is located near them.Depending on the technical characteristics of these devices can act on a distance of 10 to 20 meters or more.

- Bearing. For rolling systems suitable types of bearings:

- 301 (open).

- 60201 (closed with a metal washer on one side).

- 80301 (closed with metal washer on both sides).

- 180301 (it is closed by rubber caps from two parties).

- Special anti-vandal design (box).

- Warning light with a rocket and antenna. Such elements often have a blinking mode, which attract a lot of attention. Cheap signal lamps today produce brands such as Came, DoorHan, AN-Motors, Nice.

- Extra snow protection.

- Brush. This insert is necessary for framing the wicket panel. As a rule, it is used in a complex with a flat threshold.

For all retractable systems, there are two main rules and principles of operation:

- Optimum balance of a moving shutter. Any effort in opening and closing the structure should be excluded.

- The right set of elements of accessories. This applies to both moving and static parts.

DIY installation

If you decide to install a sliding gate yourself, you will need the following tools:

- Shovel;

- Welding machine;

- Scrap;

- Roulette;

- Level;

- Hammer;

- Drill (stock up with drills for metal);

- Bulgarian.

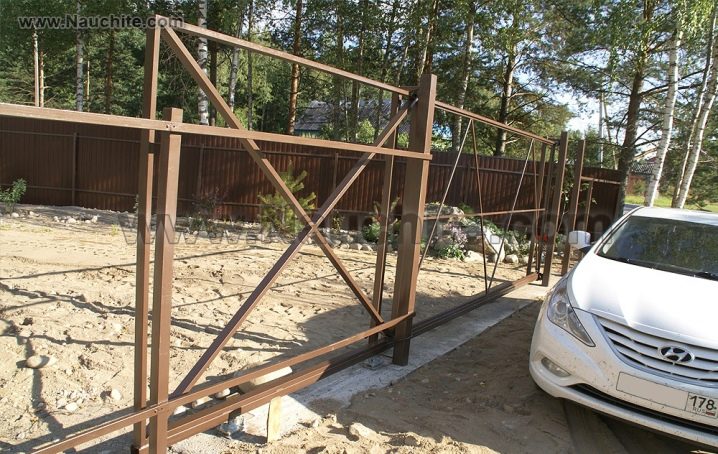

Canvas sliding gates should be installed along the fence. Take care in advance of the free space for rolling out the sash. For this, it is recommended to prepare a detailed drawing of the future construction. Buy all the necessary materials in specialized stores and proceed to installation work.

First make and install the pillars. You can use simple concrete options, solid metal pipe or wooden bars. Experts recommend concreting these parts so that they are more stable and reliable.

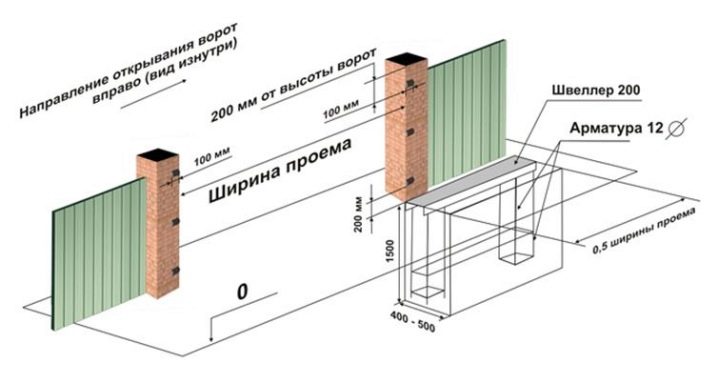

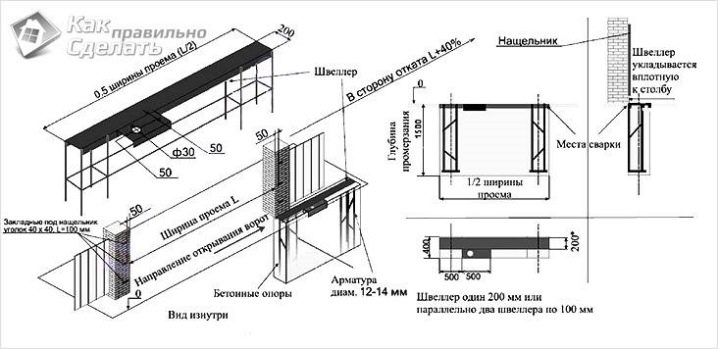

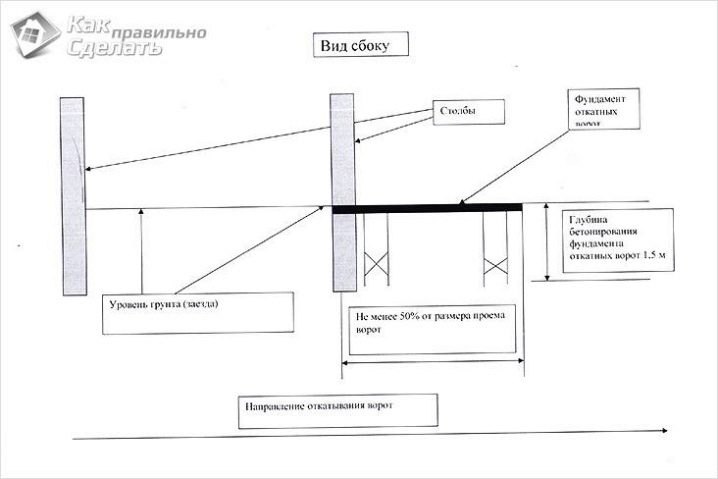

Now you can proceed to laying the foundation. It should be placed along the fence and properly concreted. To do this, it is necessary to prepare a trench with a depth of about 1 m and a width of at least 0.5 m.

As for the length, it should occupy half the size of the opening.

Next, you should start manufacturing the metal part of the sliding gates. For this, a metal channel is useful (its width should be 14-15 cm, and the length should be equal to the length of the foundation). After this, small legs of metal with a diameter of 13 mm should be welded to the channel bar. Then the metal part must be laid in the excavated trench (legs down) and concreted.

Now you need to wait a week until the concrete is completely dry. This time should not be wasted - it is better to start making sliding gates.

Another important step is the welding and painting of the shield. First, with the help of the grinder, it is necessary to remove traces of corrosion (if any) from metal bases, as well as visible oil traces. After that, the material must be degreased (suitable for gasoline). Next, you should apply a special primer with anti-corrosion properties and leave the construction until completely dry.

After applying and drying the primer, you can proceed to the cooking process of the frame. For this, a rail with a length of 6 m is useful. It must be placed so that the cut looks down. Then a profile tube should be welded to it. Its size should be 60x30x2 mm. Further on this pipe vertical racks are installed and also welded. These parts must be of the same size.

Do not forget to pre-measure all the details with the help of a square. If all actions were performed correctly, then the outer frame will be ready.

Do not forget about the last but not the least important touch - Boil the inner tube with a size of 40x20x2. At the end, it is necessary to process and grind the resulting seams so that the construction looks neat, and then apply another layer of primer to the finished web.

The shield can be painted using a conventional brush, but it is better to use a special spray gun. Then the whole process will take less time, and the result will surely please you. After the paint is completely dry, you should sheathe the base with wood, plastic sheet or corrugated flooring.

Now you can proceed to install the mechanism of the gate. The roller system must be installed on the channel. The fastening of this part takes place with the help of the side part. Then the roller system is placed on special carts. After that, the canvas should be installed along the fence and welded. As for the catchers and moving rollers, they should be fixed on the bearing pillars. For fixing these parts, you can use welding, dowels or clamps.

The gate can be controlled by an automatic system. It is quite possible to collect their own hands. Moreover, such work will save money, because autographing automation will cost much less than buying a ready-made system.But do not think that it will be easy to make your automation. This will require a lot of effort and free time.

You will definitely need to purchase a high-quality electric motor. It should be placed on a special rack.

Installation errors

If you install the sliding gate yourself, then you can make various errors and inaccuracies. The most common ones are:

- Incorrect preparatory work with the base.

- Incorrectly mounted components, as well as insufficient adjustment. Weak fastening also often causes various structural malfunctions.

- Incorrectly chosen weight of the gate under the beam. Because of this, the whole structure can sag noticeably, and it will take very little time.

- If the resulting construction began to produce unpleasant squeaks or crunch, then this suggests that there is sand in the bearings and it must be removed from there. Also, the cause of extraneous noise may be the wrong (too small) distance between the supports.

- If suspicious smudges are observed at the welding sites, this should indicate an incorrect technology for painting the material. The base must be degreased, thoroughly cleaned and coated with a primer.Only after all the above actions, you can begin the process of painting.

- In order for the pillars not to be tilted in one direction and not deformed, it is necessary to take into account the depth of soil freezing and the mass of the resulting foundation. It must be done in such a way that it is many times larger than the load itself.

How to choose?

You won't surprise anyone with attractive and practical sliding gates today. Such models are quite common. Experts recommend in the choice of sliding gates to pay attention to the materials from which they are made. Reliable frameworks and shutters will serve long and will not deliver any efforts.

Consider that such designs are more expensive than swing ones. Do not look for suspiciously cheap options, as they can be made from low-quality materials. These systems will not last long and will bring a lot of problems.

Decide what kind of gate you want to see on your site, as well as which shutters must be present in them. Based on the goals, the right choice will be made much easier, and it will not take long. Decide in advance for yourself whether you want to buy mechanical or electrical models with a control panel.Of course, the second option will be much more expensive, but it will be much easier to use it, especially if we are talking about closing / opening the gate in bad weather.

If you plan to make such models yourself, then all components must be selected correctly and carefully. Try not to overlook anything, otherwise the functionality of the sliding system will be incomplete. It is not recommended to undertake such work if you are not confident in your abilities.

If you want to get on your site a truly unique design with a unique design, then you should order it from a trusted manufacturer. The cost of such a system will be much more expensive, but as a result you will get exactly what will fully meet your requirements and desires.

For the purchase of components or finished designs, it is recommended to contact well-known manufacturers who can boast good reviews of their products. Be careful with the "garage" and "basement" firms, as they often implement low-quality careless systems.

Tips and tricks

If you want your sliding doors to last as long as possible and not lose their attractiveness, then You should rely on the following guidelines:

- An important role in the manufacture and selection of sliding gates is played by the correct measurement of the opening. First, you need to carefully measure everything, and then proceed to the direct selection of structures.

- Ensure that dirt and dust do not accumulate on the guides and rollers. If we neglect this point, then the movement of the canvas can be noticeably difficult.

- If you are making the manufacture of rolling with your own hands, then in any case do not forget that all the details must be carefully adjusted and attached to the system worked properly.

Be careful with self-installation of automation for the gate. This process is quite complicated, so the owners often call specialists for this.

- Consider the fact that the sliding gate requires special care. In many designs, the rollers do not need to be lubricated, but it is necessary to coat the wooden parts with protective compounds (if any), and also to remove them from the mechanisms.

- Always pay attention to the technical capabilities of the sliding gates and the actual conditions in which they will be. Familiarize yourself with the thermal conductivity characteristics of the structure.

- It is necessary to perform maintenance of sliding gates. This process is a universal procedure that should be performed periodically. Thanks to timely and regular maintenance, you can identify many shortcomings and system malfunctions that you did not even know about.

- Painting of all parts should be carried out only after their full installation. Otherwise, during the installation process can damage the paint layer.

Manufacturers and reviews

Today, the market has a large number of different manufacturers, producing high-quality and durable sliding gates, as well as components for them. Let's get acquainted closer with the most popular and well-known brands, as well as reviews that consumers leave about their products.

Roltek

This company known in Russia has existed for many years and produces high-quality components for gates, as well as reliable and durable automation.Also in the sale of the company are suspended systems that are in great demand.

Most consumers were satisfied with the cooperation with this company. All parts and systems from Roltec serve for a long time and do not cause any problems. Of course, much depends on how you will exploit the structure, but the manufacturer, for his part, did everything so that his products served consumers faithfully for many years.

Alutech

This large company offers sliding doors of various modifications. The products of this manufacturer is inexpensive, but it serves for a long time and in good faith. The range is so rich that you can find the perfect design for every taste and budget.

Sliding systems consisting of a metal picket fence, brilliant chocolate sheeting, metal siding under a tree or a wooden picket fence look especially attractive and stylish. The company also offers a system of different colors. Options of white, brown, red, green, silver color, and also products under wood and with draft texture are in great demand.

Consumers leave good feedback on the products of this company. First of all, they are pleased with a chic assortment of sliding structures and spare parts for them. In addition, many buyers did not upset the price of such high-quality, beautiful and reliable systems.

AMB

This famous company has been operating since 1995. First, high-quality fences, doors and grilles were produced under this brand. But in 1997, all the forces of AMB were thrown at the release of a reliable and durable gate.

Today, this company has its own automated production, equipped with all the necessary tools for the manufacture of high-quality structures. With regard to the range of AMB, then there are mobile, garage, industrial and fire doors, as well as automation for them.

As a rule, consumers leave positive feedback on sliding gates of this manufacturer. They like not only the quality of their design and wear resistance, but also relatively low cost.

Garantstroy-2003

Garantstroy-2003 also offers inexpensive sliding gates. In its assortment there are high-quality and beautiful designs, decorated with professional sheets and grilles of various sizes (20x20 or 40x40).

The cost of all products of this company includes priming and painting boards, as well as the installation of plating. Of course, the buyer chooses the colors of the design and the finishing material. The standard colors (no extra charges) in the Garantstroy-2003 catalog are green, blue, red and brown.

The products of this manufacturer also boasts a large number of positive reviews. In this case, the majority of consumers paid special attention to the democratic pricing policy of the company.

BiKoms

This company produces automatic gates of various modifications, protective walling, automated barriers, roller shutters and high-tech security systems. All designs are made of durable and reliable materials, which makes them more practical and reliable.

The products of the company "BiKoms" liked many buyers. I was pleased with the rich range and quality of materials. Some consumers were upset only by the work of the company's managers.

Marseilles

This large company is engaged in the manufacture of high-quality sliding gates from metal. The range of "Marseille" has reliable suspended industrial systems, as well as folding, hinged and framed gates.The production process of all products is fully automated, and every detail in the course of manufacturing is under strict control.

The main thing that pleased consumers who turned to this company is the cost of sliding gates. And some buyers were upset by the inaccessibility of the Marseille company.

Beautiful examples and options

They buy beautiful and practical sliding gates for both luxury mansions and small country houses. Such designs look organically in many settings, it is only necessary to correctly select the desired color and shield.

If you like elegant and rich images, then you should pay attention to the chic combo gates. For example, it can be a simple and monochromatic black shield, supplemented with a wrought-iron grille on top and surrounded by a light wooden fence with a brick frame.

Dark gates look spectacular and stylish, but you should be careful with them. For example, such a model with pointed forged parts can be installed in front of a red or yellow brick house. If the facade were dark, the dark brown or black gates on its background would look too gloomy.

The gates look especially harmoniously, complemented by street lighting fittings that match the style. For example, if there is a forged grid on the shield, then forged lamps with elegant lines will look organically next to it (on the fence).

An excellent solution for giving will be an inexpensive fence with a profiled sheet or a picket fence of a pleasant brown color. As a rule, such constructions look not striking and are found very often.

Beautiful and high gates, decorated with lacquered wood, will look organically in tandem with concrete pillars, complemented by decorative brickwork. These designs look unobtrusive and neat.

They can be beautifully beat the path under the stone and green spaces around.

Sliding gates made in the form of a chocolate shade fence look beautifully and neatly. This canvas can be combined with a darker fence in a similar design. The pillars and bases of these structures are most often trimmed with decorative brickwork. Such solutions look stylish and harmonious, especially if there are small trees near them.

Between the pillars of the base, trimmed with decorative or natural stone, it will look good solid brown gate with a partially open top. Hang on one of the posts a mailbox of the same shade as the canvas itself. Such a design will look better on the background of light paving slabs.

Charming white wood gates will look great in tandem with brick pillars and a wrought black fence. Such designs can be installed in front of a cozy house with a soft pink or beige facade and a red roof tiled. Do not leave the space empty and decorate it with large ornamental shrubs or miniature trees.

If you like more luxurious and expensive options, then you should turn to installing spectacular black gates with a wrought-iron grille, and next to them build the same dark gate with a golden patterned forging and sharp tips at the top into the fence. Such products will look good in an ensemble with a brick fence of red and sand color.

Love the rich and pompous solutions? Then you should choose or order luxurious gates of dark chocolate or black with forged weaves and golden ornaments in the form of lions.It is recommended to use such original constructions against the background of light pillars of a fence and a house with a yellow or white facade.

On both sides of the gate (on the pillars) is to install a golden decor in the form of lion heads and brown forged parts.

An interesting and hospitable look is a sliding gate and gate, decorated with dark brown and slightly coarse wood. These structures can be safely installed in tandem with a brick fence of yellow brick and red brick pillars.

For advice on choosing and installing sliding gates, see below.