How to choose rollers for sliding gates?

Sliding type gates have decent features, but are expensive. In order to save, the owners of country houses often produce sliding structures independently. Such systems include several important elements: rollers upper, end rollers, support rollers, steel rail, catchers and plugs.

Rollers are carriages or carts. They are the main component of the mechanism of movement. When selling sliding gates, they are included in the fitting kit. Each component of accessories can be purchased separately. For this it is important to know the purpose of an element.

What are we for?

If you simplify the idea of the mechanism of sliding gates, you can compare it with the train.In the role of guides are the rails, and the rollers play the role of wheel pairs. In the case of the gate rail sets the direction of motion. The process of moving the web is carried out by rollers.

Designs can vary in strength characteristics. The maximum load falls on the support rollers, which move along the guide rail. The metal of this part of the gate must be particularly durable. Steel wheels are made on high-precision equipment.

The upper rollers play the role of fixers, The best material for them is rubber. Plastic rollers are less suitable for this purpose, but their use is also allowed.

Upper catchers take on the load of the rolling limit switch. Thanks to this detail, the sash of the sliding gate gets to the designated point even under adverse weather conditions.

End rollers slightly relieve the load from the support. The limit switch works in conjunction with the catcher. To protect this part of the structure from rain and snow plugs are installed. This eliminates sagging of the web by fixing its state.

Rollers are used as an additional support. They are also supplied with a plug.This part rotates along the entire length of the canvas. It provides uniform load distribution and prevents deformation of the axis.

Roller brackets are installed so that they can provide reliable coverage of the upper frame. The bracket holds the sash strictly vertically. Opening becomes softer and free.

It should be noted that roller systems differ depending on the type of sliding gates. Different sets of accessories include various rollers. Ready-made kits for light, medium and heavy gates are available.

The most common lightweight structures, designed for weight up to 500 kg. With such variations you can close the span with a length of up to 4.5 meters. With greater weight and length of the canvas is to buy other sets, including additional elements.

Each kit plays a significant role in the performance properties of the structure. Even the smallest detail ensures reliable fixation and soft opening / closing.

Smooth operation of the street gates you will achieve only with proper arrangement and proper selection of all the components. They must be selected in accordance with the mass of the canvas. For example, if the weight of the sash being held is no more than 500 kg, choose a set with two roller carriages.

If the product is heavier, use four carriages attached to the channel bar.

Types and sizes

Rail gates - simple and convenient design. A serious disadvantage of this type is the rapid contamination of the guides. This often leads to breakage and makes the system difficult to operate. Also rail gates need constant care.

Suspended gates are a more complex and more expensive version. Their main distinguishing feature is the absence of the bottom rail. Instead, there is an upper rail. The disadvantage of this design is the inability to carry dimensional, high loads.

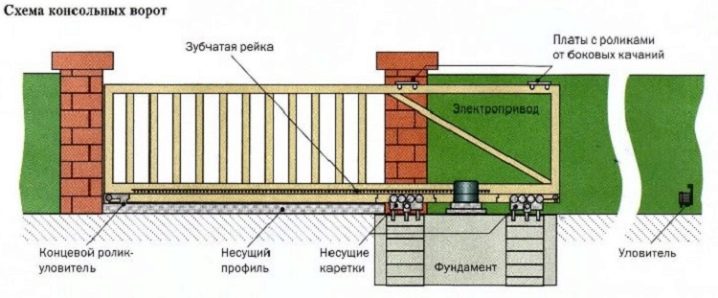

Console gate - the best option in terms of cost. However, for self-production, it is quite complicated. The design has the following advantages:

- smoothness and noiselessness;

- duration of operation;

- reliability and durability;

- resistance to any weather conditions.

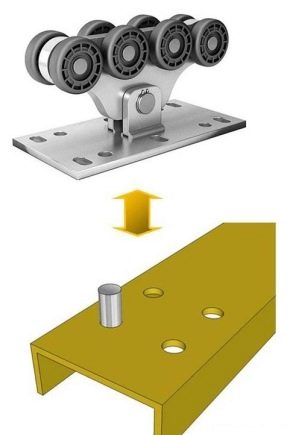

The basis of any sliding devices - roller bearing carriage.The basis of the carriage itself is a plate of steel. Reinforced bearings are attached to it. The cart itself is supplied with eight rollers, which are attached to the platform in four pairs. The platform is supplied with technological openings through which the trolley is attached to the mortgage.

The base of the carriage may be small or large. The reduced base allows more possibilities for adjusting, for example, sectional door structures.

Device design

The design of sliding gates includes a set of important components, each of which performs certain functions:

- Frame - the main "skeleton". It requires pipes that are attached to the corner.

- Canvas - the outer part of the gate. Professional sheet is the most frequently selected and economical option. For prestige and creating the effect of high prices, the professional sheet is complemented with artistic forging.

- Guide rail - massive channel. Its location is allowed both at the top and at the bottom of the canvas and frame. To rail mounted system rollers.

- Videos - vehicle movement. They provide free movement of the structure. The rollers hold the weight of the canvas and frame.

- Stand roller system. It performs the function of stabilizing sliding gates.

- Catchers and closers are locks of a gate in the closed state.

- Automation required if the type of system with automatic control is selected.

In any case, the weight of the gate is supported by roller bearing carriages. When constructing a device, pay special attention to the quality of this component. Low-quality bearings are a frequent cause of mechanical failure.

The limit switch and the lower catcher act together. The end mechanism reduces the load on the wheelsets.

The lower catcher should move the limit switch qualitatively.

The work scheme assumes that the plugs are installed at the very end. They play the role of a rail protector against rain and snow. To assemble mechanical sliding gates, these elements should be enough. A set of parts and components of the design is selected depending on the weight of the canvas.

The mass of the sliding gate is interconnected with the parameters of the opening for the entry of vehicles. They are calculated according to the dimensions of the entering vehicle. Between the support structure and the extreme points of the car, you must take into account the distance to 0.3 meters.

Take into account the properties of the soil and increase this figure to 0.5-0.6 meters.

Installation

If we consider the installation of the structure as a whole, then the simplest option includes a monolithic concrete platform. The frame and catchers are installed between the supports. The gate frame is assembled by welding. The professional flooring fastens on it.

The whole structure is complemented by a conventional opening handle. It turns out a mechanical option. Also, the gate can be set in motion with the help of electric drives. This is an automatic type.

At the first stage of installation it is necessary to dig a trench of sufficient width. Then you need to fix the metal supports. Depending on the type of soil, establish a foundation, the depth of which should be 15-20 percent. To do this, measure the depth of groundwater.

Create a protection for the bottom of the trench from the sand-crushed cushion. It will serve as protection for concrete, which is subject to destruction by moisture.

Assemble the reinforcement cage of the rods and knitting wire. On top of the frame lay the metal mortgages. The guide should be laid down and aligned strictly according to the level. Otherwise there will be a warp of the canvas.

Attach the roller carriage to the rail. Carefully fill the concrete solution so that it does not spoil the channel. Spike the concrete to let the air out. Leave the solution to “set” for about two weeks.

Weld the frame of the door from sheets with reinforcing parts. A variant of strengthening can serve as pipes of 30-40 mm in diameter. Lay the profile through the pipes and weld the reinforcement frame.

Weld the guide rail to the bottom of the frame. At the last stage, trim. Prime scale and rust with special compounds.

Fasten catchers and carriages with bearings on the gate support. Use anchor bolts to secure them. The cloth fastens on carriages and is scalded by the tacking method.

Attach decking to the door frame. To do this, use screws, equipped with rubber or silicone caps. The number of screws for fastening is calculated taking into account the quality characteristics of the metal.

If the sliding doors are made by hand, they can have individual dimensions and special characteristics of other supporting elements.

Useful tips

It is necessary to consider the following nuances:

- Be careful when choosing a ready-made set, as an error can lead to a quick failure of the whole structure.

- Consider the size of the technique. For example, the height of passenger cars is 1.4 m, the gazelle has a height of 2.5 m, KAMAZ - 2.9 m. Take into account the angle of arrival to 45 degrees.

- When constructing a reinforcing cage, it is strongly not recommended to use welding.

- Periodically wet the surface of the poured concrete for the first two days. So you eliminate the possibility of cracking.

- Select the reinforcement for the frame only after the type of the manufactured gate is indicated.

- Check the web for installation accuracy. Only then scald the entire structure.

- If you use self-tapping screws without rubber pads to fasten corrugated sheeting, over time, atmospheric moisture will “erase” the web.

- Clearly fix each part of the structure, avoiding backlash. In case of poor-quality work, the system will also quickly fail.

- Use reinforced bearings, they will provide a longer operating life.

- Use low-grade lubricants for bearings. If you lubricate the structure with other options, the rollers freeze in winter.

On how to make videos for sliding gates with your own hands, you can learn from the following video.