Wooden gates: advantages and manufacturing technology

Gates made of wood can be quite attractive, but only if you take into account all the necessary nuances when installing them. Knowledge of the technology of their creation helps a lot to save money and get the result that is needed.

There will be no need to explain to designers and developers what exactly is required from them, to carefully select the delivery package and so on.

Special features

To make the gate of wood, you can either retractable or swing; nobody makes them lifting and turning them, because this excessive complexity of the structure is not always realizable.

The type of wood laying makes it possible to make the fence either solid or intermittent, divided into blocks.

Advantages and disadvantages

The obvious advantages of wood are:

- Availability. Finding the right material in any quantity is easy;

- Relatively affordable prices. Much less than the fee for the metal on a similar design;

- Easy handling and installation. Any practically any person can make wooden gates, and installing them is much easier than installing steel;

- No need for welding equipment;

- Long enough service life and the reliability of the design being created (if everything is done correctly and the maintenance is in accordance with the norm);

- Easy to repair. Replacing the board is much easier than fixing defects in a metal web or profile.

The drawbacks of wood are also quite obvious: this is a relatively lower strength, and susceptibility to fire (special treatment only lowers it, in addition, increases the cost of the entire structure). It will be necessary to treat wood products with means that stop the process of decay.

Kinds

It is not necessary to create simple wooden structures, the use of beautiful wickets is a very smart step. The main difference is always how exactly the parts are interconnected. The traditional solution is a swinging product that is made simpler than other types and serves as a trouble-free long time.

It is possible to distinguish such groups of wooden doors as:

- "Chess";

- Made of picket fence;

- Deaf closed fences.

The trim is made both on a metal frame and on a wooden one. In urban conditions and with an acute shortage of space, retractable structures are in demand much more than classical swing systems. The only problem is that they are created much harder and require the mandatory involvement of professionals.

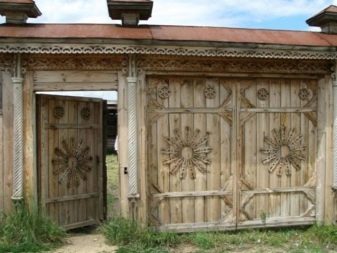

Note also that the bearing mechanism with automatic road rollers and capricious, with careless handling easily fails. It is possible to mount carved elements on any type of wooden gate both from above, and from below, and on the frontal plane.

Materials

Wooden gates will show all their advantages only with careful selection of a suitable material. In many cases, simply steel-sheathed steel frames are used - this is a relatively heavy option, but it is stronger and safer than a solid wood structure.

Expensive valuable woods are used only occasionally. in most cases limited to simple pine details.. After all, they are quite beautiful, allow you to create a pleasant appearance and at the same time are very resistant to destructive influences.Budget projects include the creation of the gate mainly from the picket.

Dimensions

Standard door dimensions are 300-400 cm wide. It should be noted that your needs may be much more important than this generally accepted standard.

When the site will be built up, it is advisable to make a wider passage so that trucks and special equipment can easily pass inside and get back. Be sure to leave the gap from the bottom edge to the ground.otherwise, it will be inconvenient to use the gate when melting snow, icing or after a heavy rain.

Style and design

Elegantly and romantically, the gates look like “antiquity”, and this is exactly the case when pine details are unsuitable. The use of larch is a relatively economical solution to the problem, and the density makes it possible to prevent the effect of many negative factors.

In the presence of sufficient funds, it is recommended to use oak and ash dark tones., with the help of these rocks to embody ancient motifs much easier. Moreover, the barrier function of such gates is at a fairly high level.

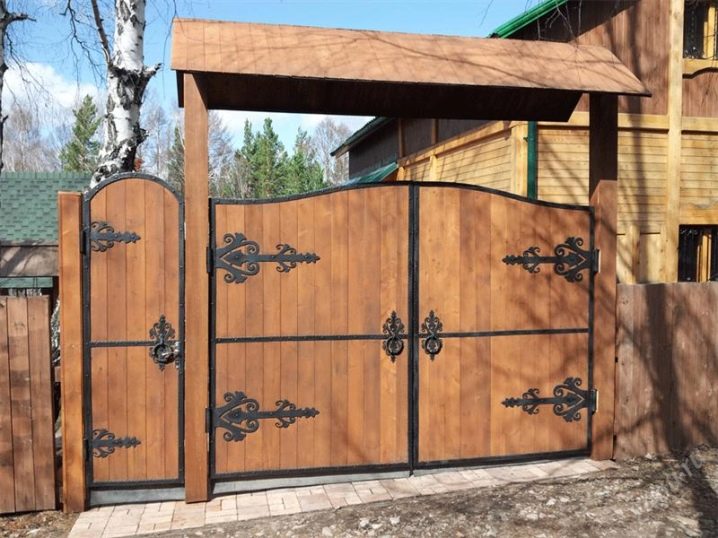

As an option, you can use iron gates with forging elements that mimic the look of natural wood. It would be even better to fill the sash with wooden details. To connect such dissimilar materials will help bolts, equipped with a semi-hollow head without edges. The frame needs to be drilled, then the boards are pulled to it by 2 or 4 fasteners. The nut is always left on the inside of the structure.

How to do it yourself?

The manufacture of wooden gates and gates is possible for anyone, even people who do not have much experience in such matters. But success cannot be achieved if you do not prepare a good set of tools and materials. It always includes:

- Pencils, rasps;

- Squares, screwdrivers, levels, screws;

- Planes, plumb lines, crowbars;

- Tanks for the preparation of concrete solution;

- Bars of wood;

- Metal constipation;

- Canopy;

- Hinges;

- A set of slats or fence for cladding frames.

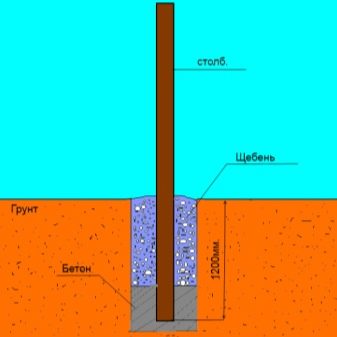

Before buying lumber, you should find out the required size (height) of the structure, the size of the gate. We must not forget that you will need to bury the support pillars of 1 m in the groundotherwise, sustainability will fail.

Before installation, each wooden pole is impregnated with fully antiseptic agents, and the underground parts are additionally treated with resins or bitumen mastics.

The territory must be prepared: they remove stones, break up lumps of earth and level it. It is desirable to mark the points of support and directions of installation with stakes, cords. It is almost impossible to do all the work alone, therefore assistants are always invited. It is possible to hang the sash only after the concrete is completely dry.

Installation of the pillars goes like this:

- Borer make a pit depth of 100 cm;

- See that the planes of the columns turned towards each other are slightly farther apart than the width of the standard gate;

- At the same time the distance should not exceed 1.2 m;

- Pit wake sand 0.05 m and thoroughly shed water to shrink it ended as soon as possible;

- Add 50 mm of rubble;

- Underground shares of the pillars are burned with gas burners or blowtorches;

- Guided by measurements, with the help of a plumb line they set up the pillar itself, fill it with rubble and tamp down;

- Top overlap stone cushion cement mortar.

The frame for the valves is formed with the help of a jigsaw, which can easily cut pieces of timber of the desired length. The ends of these pieces are drilled and driven into the holes of wooden nails.

For fastening jumpers take galvanized screws, put them horizontally or diagonally. Be sure to sheathe frame with slatsotherwise the gate will easily sag and quickly deform. Burrs and other imperfections of wood are easily removed when using planers with a well-sharpened working part.

Solid gates are formed by laying boards with nailed rails on the frame and drawing cutting lines. If the top is rounded, it is best to mark it with a compass. Lattice structures more difficult, then each rail will have to mark and cut separately. The connection of parts of the structure is simplified if you use screws on the tree.

Tips and tricks

When setting the gate, always check that it is securely locked and does not swing open by itself. Only by eliminating a similar problem, you can put the gate valve and lock.

The best option of the accessories are stainless steel constructions of factory production., a little worse is the anodized metal. Attaching gates to brick pillars is possible if at the time of their construction to leave a pair of hinges outside. It is desirable to make the connection of the overhead parts of the loops with horizontal crossbars of gates or gates by bolts.

Wooden gates or gates can be hung even on metal or concrete poles. This is done with the help of suspension assemblies, which includes a hook, nuts and clamp (a couple of knots is enough). To be able to put the lock, around the gate do a loop in such a way that the handle will also go on the handle. For painting wooden gates it is recommended to use polyurethane-based yacht varnish as the most durable and reliable. But it should be applied not less than two layers.

Successful examples and options

Even if your gate does not have wickets inside, the use of forged elements will help to make them more attractive. Against the background of dark brown wood, the use of horizontal "peak" superimposed on the base material looks very good. To get rid of excessive rigidity, such constructions are supplemented with twisted parts at the ends.But the main attention in this design project is attracted not by “peaks”, but by a stylized image of the sun in the middle of the upper part of the gate.

At the cottage, you can also use a less energetic decor of the entrance structure, which will look no less impressive. The curls and the double-headed eagle in the very center of the gate, which depart from the steel support parts, create a positive impression. The key design element are large twisted blocks and forged peaks above the canvas..

But one of the oldest, relatively simple and very elegant solutions is two homogeneous strips of twisted forging, bounded by steel lines, above and below the gate. The advantages are obvious: the minimum complexity of installation and the ability to use in almost any design site. The choice of arched gates, which are more elegant than ordinary rectangular barriers, helps to make this decision more diverse.

Here you can see that the gate with a wicket, made in style identical to the rest of the canvas, looks very attractive. Separate figured elements (rings and curls) are arranged correctly and with taste.

For information on how to make a wooden gate with your own hands, see the following video.