Electric swing gate: the pros and cons

Swing gates are a traditional form of protection both for garages and for entry into private territory. Simple automation with the help of two electric drives makes life much easier for the driver. The features of this comfortable invention and the standard rules for installing it yourself will be considered in more detail.

Advantages and disadvantages

Swing gates themselves are familiar, and therefore differ in reliability. The main advantage of double-leaf designs with automatics is the possibility of remote opening / closing from the control panel. It is especially comfortable in winter.

The disadvantage is the difficulty of installing the engine. But if you take into account all the rules of installation, in the future with the engine problems will not arise and the gate will open properly. The system allows you to adjust the opening so that the flaps are directed inward or outward by 180 degrees.In any case, a free territory is necessary, which is not very convenient.

Of the advantages of swing gates:

- Availability. This is the cheapest and most common option of all existing designs today;

- Simplicity of installation and duration of the operational term;

- With free space good provision of travel for any transport;

- The ability to use any materials for the valves;

- Independent installation of valves (if desired).

Of the disadvantages:

- poles need to dig in and concreted;

- the design requires considerable space;

- the safety of operation in strong winds;

- Installation of electricians is not cheap, as it requires two engines.

The electric part for a swing type of gate is diverse, manufacturers offer both time-tested systems and new items that are familiar only to fans of automation.

The advantages are different drives:

Linear - an inexpensive option, but the mechanism has several disadvantages. For example, the relatively slow opening / closing of the valves. In addition, the mechanisms require some refinement, otherwise they do not provide a complete closed state of the valves.

Leverage - a little more expensive than the previous one, but does not need to be improved and is easy to install: it is sufficient to properly fix the drive onto the existing structure. The advantage of lever actuators is the ability to open sash at a greater angle than linear - 120 degrees. Lever engines are different and improved opening speed.

Underground drive - has an aesthetic advantage over the first two brothers. He completely hides the fact of the presence of automation. The design is quite expensive, requires some skill for installation. Folds open 110 degrees.

Automated design it is distinguished by reliability, thanks to special blocks of rollers. They are located at the bottom of the profile base. The system is activated when the gate is opened.

Structurally, the gate can be:

- Garage with automatics working outside - often used in industrial buildings;

- entrance - are mounted at the entrance to a private territory. Such automatic gates are divided into several types according to their purpose. For example, a garden entrance gate is also a swing option. Automation for entrance structures is mounted both outward and inward.

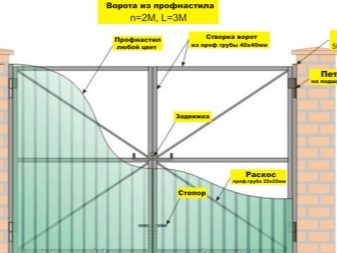

Characteristic features of any swing structures - strength, excellent functionality, convenience when moving through them. The traditional material of all types of home-made swing constructions is metal profiles or pipes, as well as iron-cladding. In the wide, wide gates, they construct a small door for the passage of people.

Features of the device

Of the features of the swing gates stand out:

- the traditional fastening of the valves has a positive effect on the durability of the structure;

- thanks to the corner connector, the possibility of profile sagging is eliminated;

- special coating profile, which is protected against rust;

- hidden fasteners, which ensures a beautiful view both outside and inside;

- extensive set of colors designs.

An important feature of automation devices is the calculation for a particular gate weight.

Before choosing a drive, consider the following factors:

Sash size

The main indicator of the electric motor - power, it is designed for the dimensions of the valves. Focus not on the average, but on the maximum possible values. In another case, the equipment without a margin of strength characteristics, will quickly fail.

The load on the electric drive will increase if the design of the gate is clogged tightly. Therefore, when choosing a device, one should take into account not only the dimensions of the valves, but also the weight.

For example, if the sash is more than 100 kg and the electric motor is selected for 200 kg, it will not last long. Particularly increase the load on the engine with the winds. The stock by weight you need to choose three or four. In the case of a 100-kg gate, this is 600-800 kg. These automatic systems are expensive, but you do not have to repair the installed device.

Opening / closing frequency

An ordinary residential building is fully secured with an intensity of 30 percent. If automation is selected for industrial areas, consider drives up to 50 percent of the intensity margin.

The cost of the engine for swing doors should correspond to the peculiarities of power, durability and reliability. If you want to save the craftsmen choose self-made manufacturing automation. For work, ready-made professional sheets and a lever drive system are used. If the swing gates and the fence in the courtyard are already installed, it is necessary that during their work was easy, without difficulties.

Independent manufacture of the drive is possible with the following components and spare parts:

- two swivel engines closers from Gazelle 3302 Katran with electric control;

- a power cable with a 2.5mm two-wire section, its length should be enough to the installation points of the power supply and Wago connectors -4 pcs;

- power supply - you can use a computer;

- radio control channel - configured using a simple relay - one or two channels;

Mechanisms of engines are mounted with a bracket from a corner of 40-20 mm. The design of the gearbox is connected to the upper part of the gate with the help of a lever, which is made of a gas support-rack.

The complexity of self-manufacturing electrics is the selection of the desired intensity of the movement of the swing doors. For better control, the power supply voltage drops or rises.

If the electromechanical drive is purchased, before installing the device is transferred to the manual control mode. To do this, use the key, which is usually attached to the device. Such an action will facilitate the change of position of the rod. After that, move the mechanism to the maximum mark and fix it on the supports of the gate leaf.

Drive the wiring and proceed to the test phase. When the mechanisms will be adjusted to the desired auto-close, equip the gate with a lock-bolt. In case of difficulty of work of the electrician, it will be possible to cope with the opening of the valves manually.

Constructions

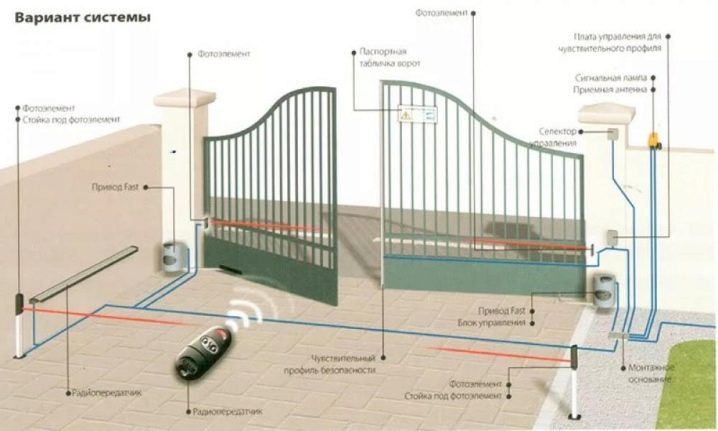

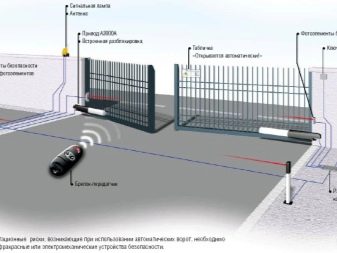

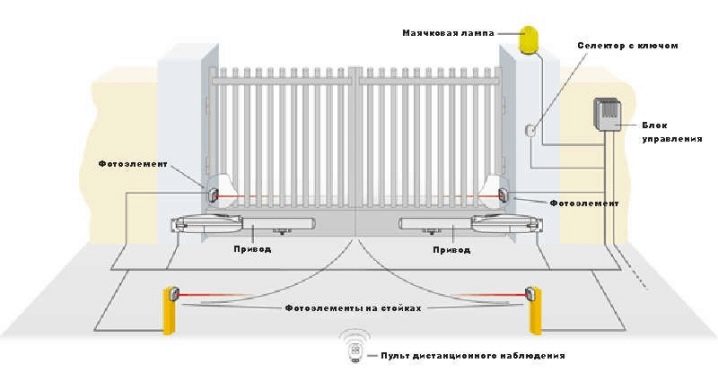

The design of automation for swing doors is quite simple. Working components are actuated from the button of the control panel or auto system. After parts of the gate reach the predetermined degree of opening, the supply of current to the engine is turned off. The gate closes on the same principle. There are more complex designs that are complemented by motion sensors, protection, identification devices.

Automation kit for swing mechanization usually includes several parts:

- control panel;

- -2 engines;

- beacon;

- photo cells;

- control unit.

The electric structures of the gate include the following components:

- rigid frame;

- support legs;

- metal valve;

- trim;

- gate loops;

- automatic system.

In the frame of swinging shutters, it is important to provide stiffeners that are installed inside.Without them, the canvas will be unstable, which will affect the integrity of the structure and appearance.

Manufacturers and reviews

Common positive feedback linear systems are products. Italian company Nice, sets Wingo, Moby, Toona. The cost of production of listed companies is democratic - 200-1300 euros. The difference in price is related to the volume of configuration - minimum, maximum. Still more important are the technical characteristics of the drives.

The same Italian manufacturer Nice offers lever engines for Walky, Pop, Hopp, Hykke, Hyppo kits at prices ranging from 350 to 1,200 euros. According to the owners, the Italian automatics has some temperature limitations.

No problem at subzero temperatures doorhan automatics. In this case, the engine with the unit has protection against overheating.

Automation of all kinds is at Fadini. This is also an Italian manufacturer. User feedback on the company's devices in most cases positive. The company is distinguished by its versatility, as it develops products that are available for different segments of the population.

An-Motors - Chinese manufacturerhaving many positive characteristics.For example, the company's products cope with frost at minus 30 degrees, as well as the unlocking system in manual mode. Drives are sold at consistently low prices - from 120 euros.

Came is another popular Italian manufacturer. Users believe these drives are reliable with good specifications. The range sells engines of several types: lever, linear kits with various characteristic features.

Known for the positive reviews component companies Roltec. Different price ranges are also presented here: Light, Eco, Euro. This is the only domestic manufacturer with a full production cycle within the country. In the market there for about 20 years. During the period of its activity, the company significantly expanded its production and acquired branches throughout Russia.

Operation Tips

After installing the automation on the swing gates, all the relevant conditions of the automatic systems can be found in the manufacturer’s assembly drawing.

For long-term operation of the automation, carefully review the characteristics and select a set that exactly matches the purpose of the gate.

An important condition for long-term service is the absence of obstacles and interference in the space in front of the gate.

Suitable automation is selected based on the width of the opening of one leaf. For example, a linear actuator is suitable for a value of 1.5 m; a similar set is purchased for the second sash.

The best way to protect the gate from damage - lubrication and preventive inspection of the system. It is not recommended to make efforts if the mechanisms for some reason stuck.

You can repair the automation yourself if you installed it yourself. Otherwise, it is better to contact the specialists.

To increase the service life of garage automatic doors, it is customary to cover the surface with a sufficiently large layer of zinc or silver paint.

About installation of automatic equipment for oar gate you can look in this video.