Drywall Fasteners: Selection Criteria

Drywall - a common material used in construction. It is used to align walls, ceilings, to create additional partitions, niches and arches. Depending on the method of application of the material, it is common to choose different fasteners.

Let us consider the criteria for the selection of fasteners for drywall.

Features GCR

GKL for alignment of walls, floors and ceilings on the market in abundance. If you do not have skills in construction work, it is better to understand the features before going to the store.

GKL are sheets of a rectangular shape with a plaster filling and facing from a cardboard. Sheets have a smooth surface, durable. Features GKL allow the use of sheets in both residential and non-residential premises. Sheets are soundproof. In addition to wall cladding, gypsum plasterboard is used for cladding sewer systems, ensuring complete isolation of the last. Sheets are easy to bend, and you can cut them with a regular hacksaw.

The smooth surface of the plasterboard lends itself to any additional processing. Sheets fixed to the wall are whitened, painted, plastered, covered with wallpaper.

Standard HL have the following dimensions: 1200 to 2500 mm. The area of the working surface of one sheet is quite large, so the work associated with lining can be done very quickly. For example, to level the walls with the help of gypsum plasterboard, you need 2-3 times less time than you would have to spend on plastering and puttying.

In addition, gypsum has a lower thermal conductivity than plaster. As a result of the use of sheets, not only sound insulation is obtained, but also insulation.. The thermal conductivity of the gypsum board is such that in the winter they are better able to retain heat and in the summer they do not allow the room to overheat. Therefore, the use of sheets is justified both in the harsh Siberian conditions and in the hot southern regions.

Of the drawbacks of GKL, it is worth noting the impossibility of using ordinary material in rooms with high humidity. Due to the constant dampness, the cardboard lining will swell and the plaster will begin to crumble. This disadvantage is relative, as manufacturers offer customers several types of GCR with different characteristic features.For example, wall material is a standard GCR type. It does not contain any special additives, and therefore the most inexpensive of all the materials presented.

Another inexpensive option GKL - ceiling. Differs from the previous version in a smaller thickness.. This is more convenient to use for arches, other curved structures.

Moisture-resistant characteristics are different sheets labeled GKLV. Sheet dimensions are standard, but the colors are usually greenish. Still on sale you can see sheets of pinkish hue. labeled GKLO. These sheets are fire resistant.. Such sheets sheathe chimneys and even fireplaces.

Recently, the sale can be seen sheets with marking of GKLVO. These samples combine the improved characteristics of moisture-proof and fire-resistant sheets.

GCRs are also distinguished by the types of edges, which are:

- straight (pc) - do not need additional processing and sealing during installation;

- with refinement (CC) - these need sealing by the reinforcing tape and putty;

- with rounding (PLC) - only putty is possible;

- semicircular with thinning (PLUK) - it is possible to work with putty, reinforcing tape, without tape;

- rounded off - Plastering is possible.

Types and characteristics of fasteners

All fasteners suitable for working with plasterboard are divided into several groups, the main of which are:

- for a framework from a tree or from a metal profile;

- for fastening the frame itself;

- in order to screw in the sheets of drywall.

- The first group of products includes elements used in the installation of frames and intended for a plasterboard profile. These special elements simplify the work, allow to achieve high-quality results even for those who have no experience in installation.

- The second group of products includes hardware, which also allows to perform work more efficiently. Screws on the market are presented in a large number of options. For certain works, you need to choose certain types, otherwise the quality of attachment will not work.

- Dowels get to the third group of products. Without them, it is impossible to carry out installation work with various structural elements. The configuration of products differs greatly depending on their purpose.

Features of future elements are taken into account depending on the method of finishing, as well as other factors. Common features of fasteners are that they are screwed into the sheets with a slight drowning, so that there are no caps protruding above the surface. The standard indent from the edge of the sheet is about one centimeter.. The types of fasteners must be determined in advance. The choice of type of fasteners is associated with the features of the frame, more precisely, with its foundation.

For the frame of the metal screws are chosen with frequent pitch threading. The thickness of the metal, which can exceed 0.7 mm, matters. Screws for this profile are selected with a drill at the end, and not with the usual point. Screws with a sharpening are used for profile, more than 2.2 mm thick.

Wood screws have a rarer threading step. This is the main difference that you should pay attention to when buying.

However, specialists distinguish more detailed types and characteristics of fasteners by special marking, which usually includes two numbers. The first value is usually attributed to the diameter of the screw, and the second value to its length. For example, if single-layer gypsum board, 3.5x25 mm self-tapping screws are used, if two-layer gypsum board is 3.5x35 mm. Hats fasteners are hidden, spherical or hemispheric. The main fasteners are with countersunk head and cross end.

More fasteners are distinguished by the composition of the material. They are made of steel, brass, there are still elements with a protective coating of zinc or phosphates. Steel - inexpensive, durable, but can rust from time. Brass corrosion resistant, but they are weak in terms of strength characteristics. Sliding fasteners of steel with a protective coating have high strength and durability.

The material from which the screw is made is easily identified by color:

- if the hardware is white, it is brass or galvanized steel;

- if the hardware is yellow - oxidized (stainless);

- if the hardware is black - it means that it is steel, hardened.

For each variant of the work should select the most suitable components.

For mounting to the frame

For this work, screws TN and TB are used - 3,5x25 mm.

Experts advise to work with a tool with a special limiting nozzle.

Screwdriver with this nozzle will ensure the accuracy of screwing in the screw, which will not spoil the cardboard layer.

Dowel "butterfly" It is installed in the hole drilled in the sheet, and when screwing in the screw it expands in space after sheet. The action of the dowel "molly" is similar to the "butterfly."

However, unlike this option Molly - metal dowel, and therefore can withstand a large load force. The "molly" dowel is also inserted into the hole in the sheet, then screwed in until it stops, which leads to the opening of the element, and then the gypsum board is attached.

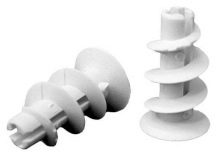

Driva - a simple and convenient dowel that does not need to be pre-drilled. The fastener "driva" is screwed in with a screwdriver or even an ordinary screwdriver. Usually it is needed in places where there will be baguettes, cornices, baseboards, other details.

Screwdriver - fastener element, which is needed to attach various items to the installed sheets. Screws allow you to tighten the screws for shelves, mirrors, paintings or lamps.

Experts advise to mount any items, even a small mass, with the help of screws. Their peculiarity is that when they fall into a void, they twist into a knot.Therefore, this element, which looks like a nail, is usually made of polypropylene, that is, it has elasticity.

For wall mounting

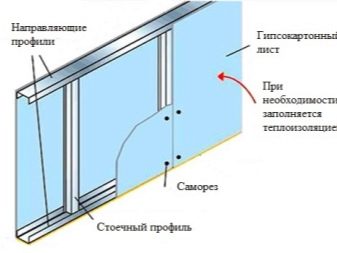

The frame is assembled first and then attached to the wall. For the implementation of the assembly will need several items.

Dowels with plastic or metal sleeve. These elements are needed for mounting brackets and profiles to the carrier vertical.

Experts advise to distinguish plastic and metal sleeves, as the first can be used for aerated concrete and hollow bricks, and the second - for solid brick or concrete.

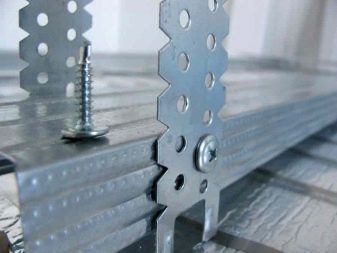

The frame is assembled when using screws for metal.

Experts advise to take a piercing self-tapping screw LN and drilling LB hardware (from 6 to 16 mm).

Another selection of fasteners associated with the weight of the frame. For example, if it is heavy, then experts advise using anchor bolts. They are screwed into the metal base of the dowel, bursting it and ensuring a secure fit.

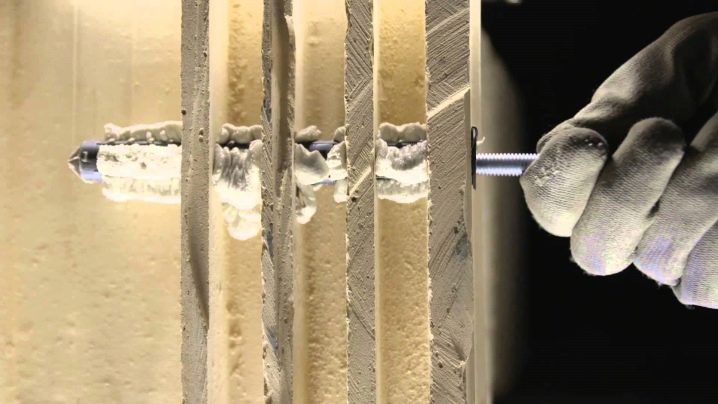

The simplest mount is a dowel-nail, which fixes the frame to a concrete or brick base. For secure fixing, a hole of the required diameter is drilled in the wall, after which a plastic dowel is inserted into it, and a screw is driven into it with a hammer.If necessary, the screw is screwed deeper or completely unscrewed. Removing the dowel is almost impossible.

Additional elements

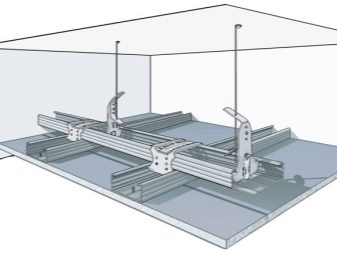

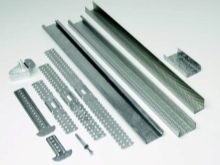

Additional elements are also used to assemble the frame:

Suspension direct configuration

Without these elements, an even and firmly fixed profile construction will not work. The suspension provides greater rigidity. The length of the products varies from 30 cm, and the width from 3 cm. The product is provided with holes that are needed for fastening.

On the market there are many variations of products, for example, there are suspensions with a soundproofing insert. Parts with a rubber element effectively prevent vibrations.

Anchors

These parts are mainly needed in the arrangement of the ceiling structure. One part of the part is a retainer, and the other looks like a spring. Despite the simple design, the detail is convenient and reliable.

Combined suspensions

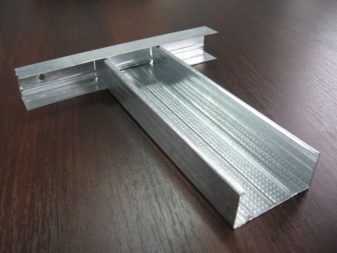

- Straight configuration connectors. This part is needed to connect the T-shaped parts of the frame. The element provides the maximum speed of work, as well as reliability.

- Swivel Type Connectors. These elements are needed when there is a need to fix the frame in a straight and inclined plane at the same time. These parts connect parts of the profile at an angle, but in the same plane. Fastener adds strength to the structure.

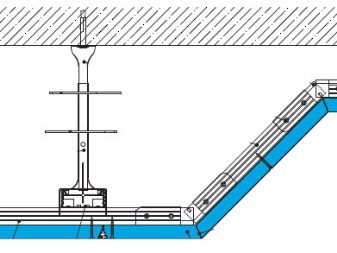

Separately worth mentioning nonius suspensionwhich is unknown to a wide circle of lovers. Not all plasterboard installers know how to use a nonius suspension. Meanwhile This element allows you to more accurately set the level of the ceiling and hang it very reliably.. The use of a suspension requires an accurate and correct understanding of the system device. The element includes several parts that differ in their features.

The bottom part is a fastener. With this node, the element is fixed to the profile and the plate with holes. The bar allows you to accurately set the frame element and securely fix it. Mount to the suspension has the form of a clamp - the solution is durable and easy to use.

The upper part of the system is a strip with holes in the sides. Through the bar with holes, the thrust is strengthened on the ceiling with screws or dowels. Products can have a length of 10 to 20 cm. This allows you to mount sheets at the right level.

The required position of the entire structure is provided by a so-called pin.. The element is a classic bracket that is inserted into the holes. Experts advise the end of the pin to bend. This will ensure better reliability of fixation.

The element is indispensable in places where you need to significantly lower the level of the ceiling and ensure reliable fixation. One detail can withstand up to 40 kg, while it is easy to install.

The cost of this product includes the price of all three components. For example, the lower part is sold for 30-35 rubles, the upper part is sold at a price of 20 to 50 rubles, and the cotter pin will cost about 10 rubles.

Another detail that is always used by experts, but rarely by amateurs - profile extension. The connector is rarely used, as many in the work with elements simply slaughter or twist them. However, if you need to do everything according to the rules, it is better to use a special connector.

The element has the following dimensions:

- height - 3 cm;

- width - 5-6 cm;

- length -10-11 cm

Material production element - metal thickness of about 1 mm. The special form of the element provides high rigidity of the connection.The process of connecting the profile with an extension is simple. The cost of products - up to 10 rubles, usually they need a little.

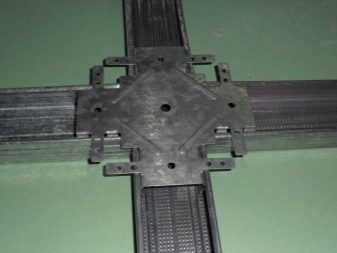

Crab Connectors

Additional details will help you quickly and reliably connect profiles to each other. Usually installed inside the profile on the carrier part. Jumpers join the system later. After the parts are mounted, the special antennae of the element are folded, and the fasteners are screwed into them. Difficult knots of a framework gather quickly and reliably thanks to "crabs".

"Crabs" allow you to connect the lintel frame from both one and two sides.

If the connection is one-sided, then the extra jumpers are simply removed. Such intervention will not affect the strength and rigidity of the system.

The main thing is to choose metal elements from one millimeter thick. It is better to refuse to purchase these products from thinner metal, since in this case the rigidity of the metal matters. The cost varies from 10 to 15 rubles.

Anchor

Another category of additional elements is special fasteners to attach any objects to the gypsum board. Do not hang a mirror, a shelf or a TV on a plasterboard wall on an ordinary screw.It will not provide a secure fit. For this task, you need a special element called "Chemical anchor".

These peculiar anchors contain an adhesive mixture inside. It creates a strong and reliable mount that even a non-professional can do.

Installation of a "chemical anchor" is simple. In the course of the work, the capsule selects the contents, the reaction begins, and as a result, the mount is very reliable.

Professionals advise you to consider the following rules when working with these dowels:

- Drill a precise hole, paying special attention if a screwdriver is used;

- fasteners should not turn at the point of occurrence;

- do not twist the part to the stop;

- For accuracy, the final screwing is best done with a conventional screwdriver.

As can be seen from the samples, the fastener options have different functions, they also differ in price.

Elements must be selected depending on the complexity of the design and method of installation. Without certain skills, this is difficult to do, so let's look in more detail.

How to choose?

On sale you can find self-tapping screws with different threads. Items are still being sold with and without the auger.Elements with the drill are intended for fixture of GKL to metal which thickness is from 3 to 10 mm.

When installing ceilings and partitions made of gypsum plasterboard, it is best to couple the 9.5 mm self-tapping screws to the drill. Professionals call these fasteners "seeds." In general, the sizes of fasteners for sale vary: 9.5 mm, 11 mm, 15 mm, 25 mm, 35 mm, 45 mm, 50 mm, 75 mm, 95 mm, 120 mm.

In the log frame, which is used for heavy structures, it is better to use self-tapping screws with small threads. In a wooden house, but on a metal frame, use self-tapping screws with fine threads.

For work with GKL in the kitchen mainly choose 2.5 cm self-tapping screws without a drill, and also "sunflower seeds" with the drill. They are inserted into suitable dowels. Self-tapping screws with a size of 3.5 cm, 4.5 cm are also used without a drill with corresponding dowels.

- If you have to work with a metal frame with a thickness of 1 mm, an ordinary screw with a drill can drill through the part. Experts recommend using “seeds” with classic dowels.

- If the profile is metal, then dowels 6 to 40 mm are the most suitable option for a plastered wall. There is not much difference between the dowels with a hat and without it, but if there is a need to hide the fastening element, it is better to choose a secret option.

- If between the drywall and the wall, in addition to the frame, there are insulation materials, the fasteners should be longer, up to 8 cm. Standard dowels 4 cm are not suitable for such work.

Armstrong ceiling hangers are usually mounted on metal dowels. For all other cases it is better to choose percussion options.

Impact Dowel - Dowel-Nail, which includes an expansion plug and a screw-type nail.

If the drywall construction is mounted on the ceiling, it is better to choose a dowel of metal "molly". It is also suitable for work with hollow structures.

To speed up the installation work associated with the installation of gypsum board, you can use a plastic dowel Driva. Installation of the element is allowed without drilland the maximum weight load can be up to 25 kg.

For the baguette, chandelier, plinth, other items, a special butterfly plug can be used. About the principles of this plug is described above.

It is also possible to choose fasteners, focusing on the price. Usually fasteners are sold in packages containing from 100 items.

The cost per package varies and is associated with many factors.For example, plastic items are cheap - up to 100 rubles per pack. Metal options are much more expensive - up to 600 rubles for packing fasteners. You can save money not only by choosing a cheaper mounting option, but also by correctly calculating the number of fasteners.

Recommendations

Consumption of the number of selectable screws for gypsum is associated with a variant of the installed frame. For example, for a wooden base the standard construction step is 35 cm, and for a metal base 30-60 cm. For multilayer structures, not only longer self-tapping screws are chosen, but they are also more often installed..

To ensure acceptable stiffness, it is customary to fasten the sheets to the multilayer frame in increments from 20 to 40 cm. Considering the dimensions of the standard GKL - 1.2 x 2.5 m, approximately 120 fasteners will be needed for one sheet. When buying fasteners, it is important to ensure the integrity of the package, inspect the screws for damage to the thread or caps.

Rejected packaging should not be taken, otherwise self-tapping screws may not be enough.

GCR is rarely attached directly to a wall, usually to a metal or wood frame.

To fix the brackets and profiles to the carrier vertical, experts recommend choosing dowels with a sleeve.which is made of metal or plastic.If the vertical is of solid brick or concrete, then you should use a metal dowel. If the wall is made of aerated concrete or hollow brick, you can do with a mount made of soft plastic. Then the profile is fixed in the dowel with a locking screw.

Screws for metal are selected from the metal profile to assemble the frame. Frequently used options:

- self-tapping screw LN;

- Drilling screw LB with dimensions of 6-16 mm.

For sheathing of the frame sheets TN TB self-tapping screws with dimensions of 3.5x25 mm are used. To fix the plates was better, you need a screwdriver with a special limiter. The nozzle allows you to tighten the screw exactly to the desired depth without breaking through the cardboard layer.

The purpose and type of dowels is determined by their marking:

- HD-S 4 | 14 MHD-S 4 | 20 - dowel for hollow structures, mounting the PN, PP profile and attachments to sheet structures;

- MN6 | 30 MN 8 | 40 MN 10 | 50 MN 12 | 60 MN 14 | 70 - nylon dowel for PN, PP, UE profiles of attachments and walls of a continuous version;

- MU 6 | 35 MU 6 | 45 MU 8 | 50 MU 10 | 60 MU 12 | 70 MU 14 | 75 - dowel multifunctional for PN PP UF profiles, attachments to hollow wall variants;

- MNA-Z 6 | 35 MNA-Z 6 | 50 - plastic anchor dowel for attaching the Mon profiles and hangers to the bearing walls and floors;

- MAN 6 | 60 - anchor wedge for fastening the frame to the bearing walls;

- TDN 6 | 40 - anchor dowel for fastening the frame to the bearing walls;

- MJP 12 | 39 - dowel for mounting attachments on plasterboard sheets.

General recommendations on the choice of fasteners from professionals:

- all types of self-tapping screws differ not only in the principle of action, but also in technical and operational qualities;

- Despite the emergence of convenient and reliable technologies and methods - the fixing of gypsum screws with self-tapping screws and dowels is most often used by both professionals and amateurs.

In the video below you will see a comparative overview of drywall anchors.