Features of the device floors in a wooden house

Floors in wooden houses should be reliable, warm, durable and beautiful. You can achieve the desired result independently or with the assistance of professional builders. Information about the features of the device floors in a wooden house is important in both cases. Firstly, because it is required for independent work, secondly, to control employees.

Process features

The floors in the wooden house consist of several layers. And in order to provide comfortable living conditions, it is important to correctly identify the component parts of the outdoor “pie”.

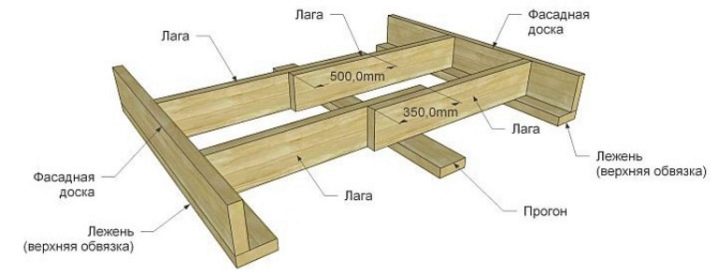

The main element of building construction for the floor is strapping. For capital buildings, it is usually performed from a powerful beam with cross-section parameters of at least 150 x 80 millimeters.

Often, the timber is replaced by several boards, securely interconnected. Trim of boards more stable.Boards are not subject to the stresses experienced by the timber.

Products used for strapping are pretreated with an antiseptic. As such, often used waste oil. Processed wooden parts do not rot and absorb moisture, and therefore serve for many years. In the absence of oil, special tools are available that are available in every hardware store.

To extend the life of the strapping on the foundation you need to lay waterproofing. Usually it is folded ruberoid in two layers.

By strapping is required to install logs. This is a wide powerful boards, which need to strengthen the edge. They, as well as strapping, need to be treated with an antiseptic. Lags must first carefully examine, repair cracks if present. Boards with major drawbacks should be replaced with better ones.

In light buildings allowed to make logs teams. For fastening components use special brackets or studs. Docking places should be backed up for greater reliability.

If the load is planned to be substantial, it is better to strengthen the structure in advance.To do this, calculate the cross section of the lag, and make their step small, from 60 centimeters.

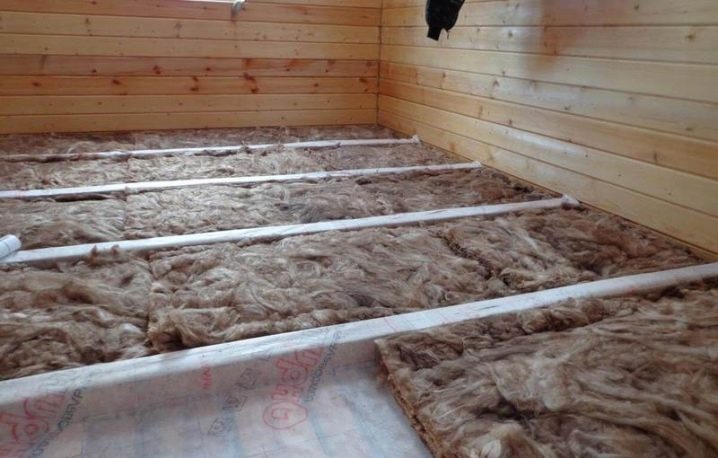

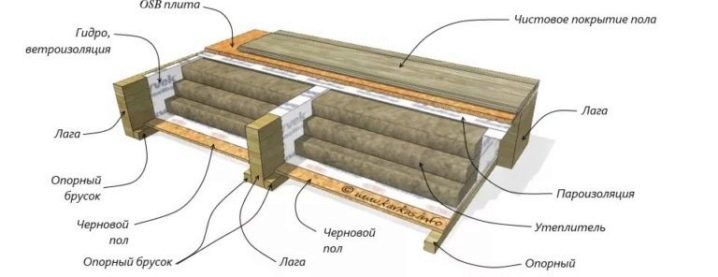

Lags are hemmed with boards, on which the membrane is laid, which prevents the penetration of wind and moisture into the room. In the formed cells fit insulation. Depending on the method chosen, this can be either expanded clay, or foam, polyethylene foam or mineral wool. Insulation covered with vapor barrier. Further actions depend on the preferences of the owners of the house. As a clean floor can be any available options, including water-heated floors.

Structure of the structure

It is not enough to build a wooden house, you need to correctly bring engineering communications, such as:

- heating;

- water supply;

- sewage;

- electrical wiring.

The abundance of engineering structures in the premises does not look aesthetically pleasing, so it is customary to hide them under the floor. The space between the lags allows you to cover most of the pipes. If there is an underground or basement under the draft floor, you can install an electric water heater, and you can equip a gas boiler room. Especially relevant location under the floor of the heater for a small shower.

When building a house is worth remembering that the wooden floor should be protected from water vapor. Modern building materials allow the structure to breathe and at the same time reliably protect against moisture damage. Excellent insulation is obtained from izospan.

Izospan is applied both at the equipment of the first floor, and the second. It is placed under the mineral insulation and above it. Non-woven material is produced in narrow rolls. When laying, separate parts should be overlapped and glued with special double-sided tape. In places of contact with lags, isospan is attached to them with a construction stapler.

The insulation layer is covered with a solid flooring. Perhaps, OSB plates are the best for this purpose.

OSB plates are widely used in residential construction. They are great for arranging floors in wooden houses. Oriented particle board floors are good for underlay boards, parquet, linoleum, carpet and laminate. But the finishing coating OSB should not be done.

For laying on logs set in increments of 50 cm, 18 mm is considered sufficient plate thickness.If the distance between adjacent lags is 10 cm longer, a large thickness of 20 mm is required. OSB plates are made by extrusion using a special adhesive. They are durable, do not rot and crack. Floors laid on sheets of OSB, do not creak when walking.

Laying is done quickly, because:

- Does not require special skills;

- the sheets have a regular geometric shape, and time for adjustment is not wasted;

- one standard plate (2500 x 1250 mm) covers an area of 3.1 m2.

Types of floors

In private wooden houses, the type of floor depends on the way of overlapping. Two options are possible: concrete (reinforced concrete slab) or wooden. On the second floor, floors are usually made of wood, since heavier reinforced concrete plates only increase the load on the foundation.

Inside the house, you can equip any of the modern flooring options: laminate, parquet, cork, tile and others.

Concrete Floors are formed by pouring screed. In some cases, this option saves construction time. The screed is fully ready for further processing after a month. Raw wood requires drying, it takes much longer.

Concrete floors in wooden houses reduce the cost of finishing the floors.A well-made screed can serve as a basis for finishing without additional interlayers and leveling the surface.

If necessary, raise the floor to a certain height under the screed sprinkle light clay. This reduces the load on the base without increasing the thickness of the screed itself.

In the new house there is a high probability of cracking the cement screed due to the shrinkage of the structure. There will be no serious damage, however, heat loss is possible. To prevent negative consequences, you can put a reliable insulation.

Concrete overlap is possible after the calculations. As a rule, such a decision is made if the capital structure has a strip foundation.

The wooden house is more suitable the same hardwood floor. The wood is environmentally friendly, does not cause allergic reactions in residents: adults and children. Natural material is increasingly used by owners of country houses, preferring it to bricks and various blocks.

Board flooring is easy to sheathe boards on both sides. Reliable fastening allows you to equip the "cake" of insulation, steam and waterproofing.The multi-layer structure can be made in the form of a floating floor. In this case, she will not have direct contact with the base and walls of the house.

Preparatory work

Regardless of whether a structure is erected on the foundation, on the ground, on screw stilts or simply on brick columns, the arrangement of the floor begins with the preparatory work.

First, prepare the walls, equipping them with ventilation holes. The lack of air access to the underground will lead to the rapid destruction of the wooden components of the structure.

Necessary for the arrangement of overlap materials need to be correctly calculated. It will not be superfluous and the stock of wood in 10-15 percent.

Installation can begin when the bars and boards are sufficiently dried. When the humidity becomes normal, the material is inspected, sorted and treated with anti-rot and fungus agents.

Rough double-layer floors are made where the foundation is laid directly on open ground.

There are several ways to lay the floor on the ground. If you lower the floor to a minimum, then you can tamp the ground, lay out a pillow of sand, gravel or expanded clay, and then pour it with concrete.True, this option is more suitable for the garage, and not for places intended for permanent residence of people.

In a light cottage house used for seasonal stay, the floor needs to be done differently. First you need to put brick columns around the perimeter. It is very important to provide the surfaces of the supports with a uniform height (to bring in one horizon). On each support you need to lay a strip of roofing material or roofing material. On the waterproofing layer, it is necessary to put a wooden lining 3 cm thick, treated with an antiseptic.

All this construction is closed by bars, along which lags are set horizontally with constant adjustment. The design is finally fixed by fasteners. On the logs is the floor, if the production is performed by single flooring.

Double floor assumes the presence of laying between the draft and finishing floor insulation, hydro- and vapor barrier, and, if necessary, other components.

Styling methods

Rooms in a wooden house will become presentable, and staying in them will become truly comfortable if the flooring is in harmony with the walls. Uniform material will make the interior of the room complete.

The choice of the type of wood for the floor depends on:

- material opportunities;

- purpose of the room;

- planned loads.

With an unlimited budget, choose the most beautiful, durable and dense materials from foreign countries. Exotic trees growing in tropical forests have unique properties. They withstand strong moisture, are easy to handle, resistant to abrasion. In addition, the boards of these trees differ in beautiful colors. For example, merbau wood may be golden-orange or red-brown. Floor purple can be done if you use rosewood. And the striped floor covering turns out when buy very expensive wood zebrano.

Softwood planks, including pines and spruces, will not be expensive. From such floors the room is filled with substances that are beneficial to humans and have a pleasant aroma. The tree always stays warm, so it's nice to walk barefoot on the floor.

Aspen and lime boards are required for showers, baths and saunas. They do not emit resin, are resistant to water and high temperature.

On the veranda, open to precipitation, the floor is best made from corrugated oak or larch boards.

The thickness of the floorboards should be chosen taking into account the distance between adjacent lags. At a distance of 600-700 mm, a thickness of 40 mm is sufficient. If the spans are larger than the specified size, you should give preference to boards with a thickness of 50 mm. As for the width, it is set by the design project or the preferences of the owners.

If you decide to hold the flooring device with your own hands, remember that it is inconvenient to lay wide boards alone. In addition, the larger the web, the greater its shrinkage. The results of this inevitable process can affect the quality of the wood flooring. For this reason, it is better to take narrow and not too long boards.

One of the ways to install the floor is to install it in a run-in manner; in this way, the joints of the ends of the boards should not coincide in adjacent rows.

If plywood is used as a base, the parquet boards are glued with mastic or glue and additionally fixed with screws, as is the case with a solid board. It is necessary to glue over the entire area, without voids.

In addition to the traditional direct form of laying, use a diagonal. Particularly elegant in a spacious room looks laying at an angle of 45 ° to the wall.

Expert advice

Arrangement of the floor requires thorough preparation, quite a lot of time and physical effort. Despite this, many believe that self-installation is possible without the involvement of specialists and additional costs. Indeed, by showing perseverance, following the step-by-step guide, you can do without outside help and significantly save money.

If it is necessary to re-floor the floor, the worn out top coat is removed, the condition of the substrate is checked and, if necessary, repaired. Lags with flaws should be replaced, as well as other components of the base affected by rot or fungus. During the overhaul of floors, they change wetted or packed insulation, as well as insulation.

If the logs are in good condition, but begin to sag, you need to put a lining under them, for example, from plywood smeared with parquet glue.

Instead of expensive membrane films, asphalt can be used as a protective agent against moisture.

When laying under the topcoat is performed with sheet building material (fiberboard, OSB, plywood), it is attached to the base with self-tapping screws. Mounts should be located at a distance of at least 20 mm from the edge of the sheet with a pitch of about 150 mm. The caps of the screws should be embedded in the body by 3 mm. The resulting grooves should be puttied. No filler finish at the attachment points will be adversely affected. And after some time, traces of poorly performed work will appear on it.

The black floor can be made from unedged board after removing the wane and thorough processing with an antifungal agent.

In living rooms, plywood will be suitable for leveling the base for final finishing. Plywood has a flat surface, does not deform over time, so the flooring remains in good condition for a long time. You can not make the flooring of plywood in the bathrooms and kitchens, as it is not suitable for rooms with high humidity.

Never allow direct contact of wood with concrete. Even with an ideal surface of a concrete (cement) screed between its surface and the boards should be a separating element.It can be very thin and consist of mastic or rolled polyethylene foam. In the latter case, the individual sheets are laid with overlap.

In order to trim the floor in a private house, making it unusual, you need imagination and appropriate materials. Everything is possible here: from unpretentious linoleum and pine boards to parquet and fashionable self-leveling floor 3D.

The only thing that is not recommended (for fire safety purposes) is to equip an electric thermal floor.

There are various options for flooring in a wooden house. There are so many that everyone will find a suitable and cost, and in appearance. Which one to choose is up to you.

To learn how to properly install the floor in a wooden house, see the following video.