Bulk floor Ceresit: application tips

Bulk floors now become very popular due to the simplicity of the device, neat appearance, long service life and excellent strength. Special materials provide an attractive and reliable coverage in a short time without the expense of enormous effort. Especially popular products that allow you to get a self-leveling floor. For example, good reviews are Ceresit products.

Materials

Smoothing agents of the Ceresit trademark are the mixtures from which the self-leveling self-leveling floor is made. The task of the levelers is to level the floor before laying the covering or with a screed, as well as to fix floor defects. Names of universal equalizers (from 3 to 60 mm):

- CN 173;

- CN 175;

- CN 175 Super;

- CN 178.

In addition to universal, in the line are self-leveling thin-layer mixtures (from 0.5 to 15 mm):

- CN 68;

- CN 76;

- DD;

The most popular product in the line of the Ceresit brand with excellent reviews is a mixture for the manufacture of self-leveling floors with a thickness of 6-60 mm Ceresit CN 173.This material performs the function of smoothing the base and preparing the floor under the floor covering. It can also be used as a base, as well as for installation of screeds in rooms. CN 173 has a consumption of about 1.6 kg per 1 m2, it dries quickly and, with certain skills, it allows you to get a finish result without cracks.

Application tips

The first step in applying a self-leveling floor is to evaluate and prepare the foundation before work. We can distinguish absorbent and non-absorbent base types. The first includes concrete and cement screeds, the second - ceramic tiles, stone or wood floors, and asphalt screed. Depending on this type of mixture is selected. The preparatory work includes cleaning, grinding cracks, dedusting, getting rid of excessive moisture and maintaining the required temperature in the room.

Such preparation will facilitate the subsequent application of a primer, and this is the next mandatory step for obtaining a result without cracks. Properly selected, depending on the type of base, the primer will strengthen the top layer, protect it from moisture and dust, and improve the quality of further work.Applying a layer with a brush or roller will provide a uniform coating, and further drying will provide the best effect.

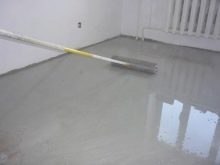

The next stage is a basic alignment using a tie-laying method. It is needed if the base has significant irregularities. For this purpose, a special mixture is harvested, beacons are mounted, the solution is laid on the base and the seams are sealed. If this is not required, then you can proceed to the finish alignment. The next step is one of the main stages of the whole work. It begins with the preparation of the mixture according to the instructions indicated on the package. Then it is quickly distributed with a special tool - doctor blade over the entire surface, following from the far corners towards the exit.

To remove the bubbles from the finishing layer after laying, they pass through it with a special needle roller. Following the drying process, the chosen flooring is laid.

Preparation of the solution

This step is one of the main steps to obtain an even and reliable coverage after all the work is completed. To begin with, they prepare a construction mixer or a drill with a nozzle, one large or several containers of 10 liters in volume, in which water and dry mix will be mixed.As an example, we use the quick-hardening self-leveling flooring CN 173.

To create a solution, the required amount of pure water is measured, in our case - 5-5.5 liters per 20 kg of dry mix. Experts do not recommend using cold water: its optimum temperature ranges from +15 to +20 degrees. Dry mixture of CN 173 is gradually added to the container with water, while constantly stirring the solution. Stirring is necessary to obtain a homogeneous consistency of the working mass.

Another important nuance in the preparation of self-leveling floor "Ceresite" is the speed of mixing the solution. Mixing components using a mixer or a drill with a special nozzle should be carried out with a rotational speed of 400-800 revolutions per minute.

Ceresit CN 173 belongs to the quick-hardening mixture, therefore, all ready-made mortar must be distributed over the base of the floor within half an hour from the moment of preparation.

Advantages and disadvantages of the self-leveling floor Ceresit

The undoubted advantages of the Ceresit self-leveling floors are, as mentioned earlier, a small material consumption per 1 m2, a small layer thickness, which, on the one hand, does not affect the height of the ceilings, and on the other, it allows you to get the finished result rather quickly.The innovative patented composition of self-leveling floors of this brand provides a quick hardening of the mixture and complete filling of all kinds of grooves and cracks, which as a result guarantees a flat floor covering.

Buyers will also appreciate the advantages of a self-leveling mixture, such as ease of application (both manual and mechanized), high wear resistance and the absence of cracks over many years of use. Reviews of experts, moreover, show that These floors can be combined with various “warm floor” systems.

Disadvantages of self-leveling floor "Ceresite", in fact, does not exist. It all depends on the professionalism of the workers laying the mixture, the implementation of instructions and special instructions. For example, the product CN 175 is not intended for outdoor installation because it requires dry conditions without drafts. In case of violation of this requirement, the finishing layer is covered with cracks. In addition, the rapid hardening of the mixture, of course, is a plus only if the installation work is carried out quickly. This master is able to distribute the composition on the surface in less than 30 minutes, while not forgetting about leveling.

But not only specialists can achieve an excellent result: subject to all the conditions mentioned above and carefully conducted training, even newcomers will be able to get even coverage.

Review of the flooring Ceresit CN 175, see the following video.