Thickness of a bulk floor: subtleties of filling

To date, self-leveling floors are gaining more popularity. On the construction market of such coatings represented a huge variety. That's just which one to choose, which mixture consumption will be required, which floor thickness is needed, and not everyone knows how to save money in this matter. Having learned about the right technologies and the intricacies of its fill, you can make a high-quality coverage without spending all your budget.

Kinds

In order to choose the right coverage, it is important to know about what they are and for what room they are intended. The sales assistant can not always help you make the right decision, so let's look at what types of self-leveling floor are and what they are for:

- Polymer There are epoxy, methyl methacrylate, polyurethane. Polymeric floors are a universal covering which possesses excellent mechanical and decorative properties.That is why the range of their application is very large. They have excellent self-leveling floor characteristics. They can be used in residential, industrial and civil construction: in garages, warehouses, parking lots, trade pavilions, at the enterprises of the medical and food industry, in homes and apartments, sports facilities. The thickness of such a floor can be from 2 to 40 mm.

Methylmethacrylic floors are also called industrial floors. This coating is suitable for areas with high mechanical loads. Most often, this mixture is used for the floor in industrial shops, parking lots, garages, warehouses, as it is resistant to temperature extremes, vibrations, mechanical loads, water and aggressive influences. Coating thickness is usually 4-6 mm.

The scope of polyurethane floors is wide enough - food industry (dairy plants, bakeries, meat processing plants, breweries, warehouses), chemical industry, public places, parking lots. Fill this floor with a thickness of 5 mm.

Epoxy floors are classified as polymeric compounds,but they do not differ from them in their versatility and breadth of use. They are also used in industrial and residential construction. The optimum layer of this coating is 2.5 mm.

- Mineral. Mineral floors are used in rooms with moderate humidity, used for finishing alignment of a very curved surface, for arranging heated floors. Accordingly, this type is better to use in housing construction. Basically, mineral compounds are used as a base or middle layer due to low cost materials, for example, under tiles and a floating floor. Mineral floors can be of different thickness.

- Acrylic-cement. Acrylic-cement coating is an industrial classic mixture, which is poured in areas where the load on abrasion is increased. Such premises include warehouses, “wet” production, car services, garages. The thickness of acrylic cement is from 10 to 20 mm.

- Self-leveling cement-polymer. Self-leveling cement-polymer composition is used for repair work on magnesite, ceramic and wooden surfaces. This is the most common type of coating that is used everywhere.Coating thickness can be up to 5 cm.

- Antibacterial. Antibacterial coatings are relevant for food production, restaurants, kindergartens and other public facilities. They are also used in rooms with high humidity.

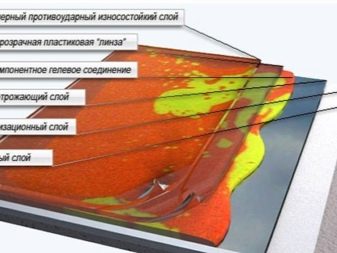

The thickness of the coating, they are divided into:

- Thin layers - thickness is less than 1 mm;

- Solutions with an average layer - up to 5 mm thick;

- Highly filled coatings - thickness up to 8 mm.

Installation

Each coating has its own unique composition, thanks to which the characteristics of the mixture are formed. The composition of the epoxy mixture includes resin, which is characterized by strength and durability. This coating is of several types:

- thin layer - the thickness of the casting is up to 1 mm;

- bulk - more than 1 mm thick;

- quartz-filled - thickness greater than 1 mm, but its main difference is a layer of quartz sand.

Methyl methacrylate floors are made from flexible methyl methacrylate polymers and copolymers with the addition of quartz sand and a filler. Such a composition dries within 15 minutes, it is easily repaired without breaking the tightness. This is a thin-layer composition with a thickness of 2.5 mm to 4 cm.

The polyurethane mixture consists of urethane, which is formed by the reaction between the polyol and the isocyanate. Due to this reaction, it has high chemical and thermal resistance. There are:

- polyurethane floors;

- polyurethane cement floor.

The technology of filling the floor with a polymer mixture requires compliance with the following steps:

- Worktop preparation. This stage implies a cleaning of debris, grease, dirt. And also it is necessary to level a floor from roughnesses.

- Padding. An important stage, which improves the adhesion of the layers.

- The application of the base layer and decoration. The polymer composition is applied on a flat surface with the necessary layer. To make the surface even, wait about 10 minutes. The drying process lasts about 5-8 hours. The last decorative layer is applied only 5 days after complete drying.

The thickness of the polymer-based coating should be from 2.5 to 5 mm.

Acrylic-cement coating contains high-quality cement, polyacrylic copolymers and special filler. This mixture of substances ensures durability and resistance to moisture. The minimum thickness is 10 mm, and the maximum is 20 mm.When casting such a composition, you can forget about waterproofing.

The technology of mounting such a floor is as follows:

- Preparation of the subfloor. It is important to remove the protrusions and cover the gaps. Remove all small debris with a vacuum cleaner.

- Primer surface for increased adhesion.

- Application and leveling of the solution with a spatula. It is important to work quickly, as the mixture will polymerize for 20 minutes.

- To get out the excess air, the mixture is rolled with a needle roller.

- After a couple of hours, the surface is covered with a finishing layer (varnish, resin).

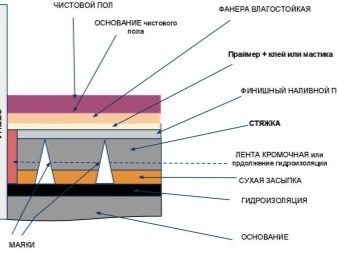

Mineral coating consists of sand, cement, claydite-concrete. It can also be used for insulation under the mineral composition of polystyrene foam. Subsequently, such a floor will require a finishing coating. Allocate:

- The base layer is from 10 to 80 mm thick, dries for about 12 hours;

- The middle layer is from 7 to 30 mm thick, the drying period is about 4 hours;

- Finishing layer - 3-10 mm, dries in 4 hours.

Self-leveling cement-polymer composition has good adhesion to the base layer. This is one of the types of concrete pavement, which consists of cement mixtures, quartz sand, pigment and polymer additives.The optimum thickness can be up to 5 cm. May have a matte and glossy surface.

Antibacterial floors are a resistant coating system that removes mold, mildew, and pathogens.

The thickness of the self-leveling floor depends on the load that the floor will sustain. In residential areas, it will be 1.5 mm. This will be enough to not remember the repair for many years. But it is important to consider the purpose for which this or that room will be operated. The choice of material and layer thickness also depend on this.

On average, for standard living quarters the thickness can be from 2.5 to 5 mm.

Polyurethane material with a thickness of 5 mm may be suitable for the kitchen, since it is there that heavy objects often fall onto the floor, and this coating has elastic properties.

For the bathroom are perfect epoxy compositions. This is due to high resistance to moisture. The thickness of the layer will be about 1.5-2.5 mm.

Methyl methacrylate compositions are suitable for the hallway and living room. The material layer is 3-4 mm.

But on industrial facilities a layer of self-leveling floor can vary within 10-15 cm, since the load on it in such rooms is much greater.Therefore, saving on the material, the coating quickly leaves the layer.

To determine how much you need a mixture, you need to take into account the thickness of the coating. For example, if the total area of the premises will be 50 square meters. meters, and the thickness of the self-leveling surface - 2 mm, then you need to purchase about 100 liters of material. If the mixture is more dense, then 150 liters. If you want to reduce consumption, use additives that increase the volume of the material.

If the thickness of the self-leveling floor is less or more than the allowable value, then its service life will be significantly reduced.

Professional Construction Tips

To get high-quality flooring at a low price, you can use the following techniques:

- If the base is slightly curved, a sander can be used to smooth out roughness and unevenness. This technique will allow you to save on the purchase of building material.

- In order not to buy a primer, you can do it yourself. This will require a small amount of the mixture for self-leveling floor and water.

- For large drops, it is better to use concrete solutions for leveling instead of a bulk composition.

For detailed instructions on how to lay the self-leveling floor, see the following video.