Bulk floor Knauf: pros and cons

Thanks to the ease of installation and operation, self-leveling self-leveling floors are becoming increasingly popular. The quality of products of famous brands is not satisfactory. It fully justifies the relatively high cost of production. Knauf is considered one of the most famous manufacturers of building mixtures.

Range

Knauf products include cement and gypsum-cement floors.

Cement lightweight screed "Knauf-Ubo" consists of cement and expanded polystyrene granules. The cost of this product is relatively low.

Bulk floor "Knauf Boden" is available in 3 versions:

- "Knauf Boden-15" (production of screed from 2 mm to 15 mm);

- "Knauf Boden-25" (production of screed from 10 mm to 25 mm);

- "Knauf Boden-30" (production of screed from 25 to 80 mm).

The type of mixture is chosen depending on the thickness of the cast layer. It is based on plaster, which allows the floor to dry quickly and gives it flexibility. This building material is used for insulation and sound insulation.

Part "Knauf Boden" Extra strong plaster and quartz sand is included.To prepare the solution, 6.5 liters of water are added per 25 kg of dry matter. The mixture should be gradually poured into the water, continuously mixing the solution with a mixer so that there are no dry lumps left. A needle roller will help with air bubbles.

It should be used within half an hour.

The finished liquid mixture is applied mechanically or manually. On average, it takes 3 hours to freeze the floor. For complete curing of the material will take from 2 to 8 days. In each case, this indicator depends on the temperature in the room and the thickness of the poured layer.

Universal self-leveling waterproof floor "Knauf Tribon" It is used to create a particularly strong screed, the thickness of which varies from 1 cm to 6 cm. Any decorative materials can be laid on it without additional surface preparation. In addition to building plaster, Portland cement, quartz sand and special modifying additives are included.

Specifications

The technical characteristics of Knauf dry mixes provide simplicity and speed of installation and excellent operational properties of the coating. They are also distinguished by the following parameters:

- Plasticity of the solution saves the time of installation of the floor.

- The composition of the mixture provides good sound and heat insulation.

- The multicomponent composition is simple in preparation for work: you just need to dilute the mixture with water according to the package instructions.

Advantages and disadvantages

Product Strengths:

- Self-leveling saves time and effort. The spilled mixture is self-leveled on the base due to the presence of polymer additives.

- Layer thickness varies at the request of the owner of the room. In some cases, a few millimeters are enough, for example, when pouring the final layer. For other options, you need a few centimeters, for example, if you decide to use Knauf products also for screed. The thickness of the layer may depend on the need for additional sound and heat insulation.

- The speed of installation. The solution can be applied within an hour.

- Rate of hardening. Walk on the floor and continue to repair after 6 hours. Base strength is achieved in two days.

- Paul Knauf does not shrink, does not crack when cured.

- Durability of a plaster bulk floor. This characteristic is provided by special modifiers.

- Universality of mixes.They are suitable for creating heated floors, absolutely any finishing materials (parquet, laminate, tile, carpeting) can be laid on the self-leveling layer.

- The composition of the mixture includes environmentally friendly components that do not harm human health.

The disadvantages include:

- Enough high price. For example, the cost of one package of the mixture “Knauf Boden” is in the range of 450-550 rubles.

- A huge number of fakes due to the high demand for the products of this company. When purchasing such a product, we no longer have to talk about the quality of the self-leveling floor.

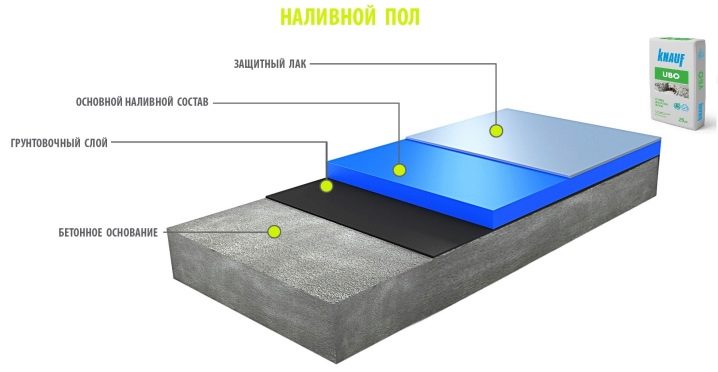

Pouring process

In order to fill the floor is not peeled off, you must use a quality primer. If you save on this material, the floor can be completely ruined.

Before pouring, you must install the beacons, which control the thickness of the coating. In the corners of the room, at the junction of the slabs with the walls, you need to lay insulating edge tape to prevent leakage.

The surface covered with a primer should be thoroughly cleaned from dust.

In accordance with the proportions of water and the mixture indicated on the package, a solution is kneaded, which is then poured onto the floor, achieving the desired layer thickness.Bulk mixes are plastic, spread easily, resemble thick kissel in consistency.

If you prepare a self-leveling solution in large portions, you can not have time to fill it. When the mixture prepares the assistant, the pouring speed and the quality of the coating increase significantly.

The solution is poured at one point, slightly leveled with a squeegee and rolled with a needle roller. Immediately after pouring the floor, it should not be exposed to direct sunlight.

Do not use fans or heaters to speed up the freeze.

Reviews

In their reviews, consumers note fast drying, strength of the liquid layer, ease of operation, frost resistance, excellent thermal insulation properties of the material. They urge not to save on the primer, because the quality of the floor also depends on it.

All buyers unanimously acknowledge that If technology is followed, Knauf blends allow you to create a flat and durable floor.

See the Knauf for the installation instructions for the self-leveling floor, see below.