Damper tape for floor screed: the purpose and types

In order for the floor to be durable and serve its owners for a long time without losing an attractive appearance, the builders think through the technology of its installation to the smallest detail. An important detail in creating a quality flooring is the damper tape.

The first danger that threatens the integrity of the screed is the extreme temperature regime of operation, therefore, the damper tape for screed floors, the purpose and types of which allow for the free expansion of the screed, and is used in interior construction work.

Special features

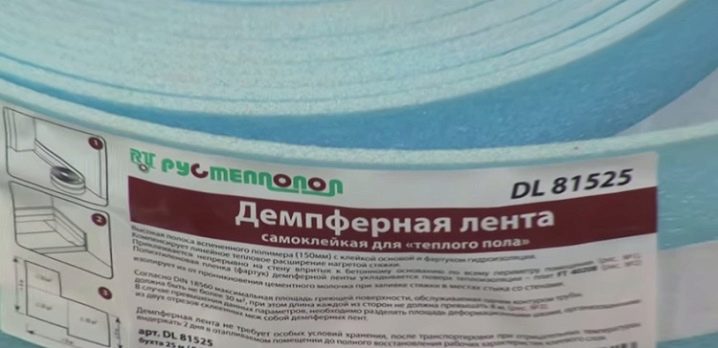

This product of construction craft is a strip of foamed polyethylene or styrene. It has certain parameters of length, width and thickness, one side of the damper tape is self-adhesive, the other has no sticky layer.

Other names of the damper tape - edge, edge. Regardless of the name, the properties of this product do not change. It is realized in the form of not too wide canvas coiled into a roll, the length of which varies from 10 to 100 m (usually 20 m) in different cases, width from 5 to 15 cm, and thickness from 3 mm to 1 cm. Throughout the entire length of the strip centimeter can be seen small incisions. Such a detail is necessary in order to make it easier for masters to tear off the extra length of the material.

Edge tape performs a number of functions. Its main purpose is:

- create additional hydro and thermal insulation;

- absorb vibrations of a different origin;

- fill the flaws on the surface;

- form compensating folds;

- to act as a barrier when pouring mortar for the screed.

The material from which the edge strip is produced has good technical properties:

- Does not interact with moisture, which eliminates the possibility of rot, mold and other troubles of biological origin.

- The laid edge tape does not change its structure even under the influence of aggressive media (ultraviolet radiation, alkaline concrete, etc.).

- It has the ability to return to its original shape after prolonged compression or stress.

- Easy and convenient to install. Does not require special skills for styling.

Edge tape is used in such cases:

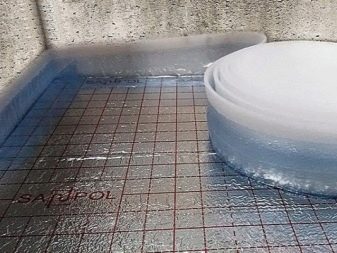

- for laying warm and bulk floors;

- to create a "rough" base needed for a floor covering of one type or another;

- for concrete pavement (waterproof coating around the structure);

- for the foundation.

The above criteria and determined the advantages of the edge tape, which include:

- excellent elasticity, which allows you to perfectly perform the main task - polyethylene easily bends and easily returns its original shape;

- optimal thermal insulation properties. This feature reduces the level of heat loss through the gaps between the walls;

- excellent sound insulation capabilities;

- Edging tape does not allow extraneous sounds and noise;

- hypoallergenic, harmless to the environment and humans;

- perfect waterproofing;

- long service life of the product;

- ease and simplicity of installation;

- excellent resilience to aggressive factors of the external environment;

- absolute resistance to biological agents (the tape does not rot, does not corrode, does not react to ultraviolet radiation).

Inherent damper tape and disadvantages, but attributed to them can only be expensive. The use of this band in the repair and construction works, especially in large quantities, can deal a significant blow to finances.

However, due to numerous advantages, this product is often used and, as practice shows, there is no negative feedback from the damper tape.

Species

Different manufacturers make different additions to the parameters of the basic material of the edge tape. However, despite this fact in the modern market of building materials there are only three types of damper tape:

- Standard self-adhesive strip. This is a long, gathered into a roll tape of styrene or polyethylene foam. Easily attached parallel to the walls of the room.

- Strip with a skirt (basky). The last in this case is a dense material that extends beyond the edges of the tape by about 30-100 mm. The skirt is durable; when the tape is fixed, it is lined on the floor along all the walls, partially covering the floor covering. The tape with a skirt happens usual and self-adhesive.

Thanks to the use of this type of material, the tightness of the angle increases significantly.

- Self-adhesive, with an adhesive strip on the back side. In the process of laying the edge strip, the protective layer in the form of a paper glossy tape is removed from it, and the tape is easily glued to the desired surface with a sticky side. Due to such a connection, the product does not slip while the field is filled with a screed solution.

How to choose?

Such material as deformation edge tape is sold on the market in large quantities and assortment. Therefore, to choose the tape of the desired size is quite simple. Packages in which it is sold are easily transported, because the product is very light due to its porosity. The average cost of it depends on the manufacturer and is about 300-400 rubles per roll.

But not always the purchase of building tape is successful, and in the process of work, significant flaws in the product become apparent. Therefore, when choosing this kind of product, you need to pay attention to such factors:

- The integrity of the product and the absence of deformation. The tape in the roll on all sides should be smooth, without obvious damage, no curves and torn edges should not be.Holes, dents and other defects indicate improper storage of the goods, therefore, such a product is not worth buying, otherwise it may adversely affect the quality of construction work.

- External parameters The canvas must be clean, with no visible defects.

- Density. If there are gaps, voids and crevices in the roll, then there is a high probability that the adhesive surface is damaged, which means that it is unsuitable and should not be fixed.

Not the best solution would be to buy too cheap tape with defects (markdown). The quality of this product may suffer the final result of work on the creation of screed.

Piling

In order to properly lay the damper tape around the perimeter of the room, it is first necessary to determine its required size. Considering the necessary multi-layer basis, and optimal band parameters are determined.

The following steps for fixing the damper tape and creating a quality tie must be performed in stages:

- Before fixing the foamed polyethylene, the surface of the walls and the floor must be cleaned from dust and debris.

- For a better hitch, the surface on which the tape is placed should preferably be treated with a degreasing mixture and dried.

- Work should be carried out at a positive temperature.

- The excess parts of the product are cut, but if later a plinth is installed on the floor, the extra parts of the edge strip can be left.

- If you are laying a ribbon with a skirt, it is important to ensure that this part is well covered with mortar.

- During the arrangement of warm floor tape is also needed. It must be placed between the heating systems and the vapor barrier or under it.

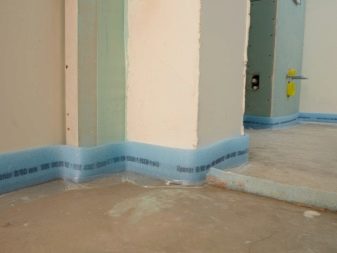

- Laying foamed polyethylene does not provide for voids. The room must be fully glued around the perimeter. It is also undesirable to make frequent joints from the segments.

- At the end of the installation, you can walk along the tape with a construction roller - it will remove minor flaws and additionally press the strip against the wall. Only after this stage, you can begin to fill the screed.

If there is an adhesive layer on the tape, it is enough just to press it with an adhesive side to the wall around the entire perimeter of the room. Option with a "skirt", bent to the floor so so that no liquid (moisture) can get under it.

There are alternative ways to mount the strips. These include:

- Furniture stapler. In the case when the walls of the building are made of foam concrete, the tape is fixed with a stapler,using metal braces.

- Screws and puncher. Ideal mounting for brick walls. Screws are screwed directly into the wall. First, holes are created with a perforator, and then dowels and screws are inserted into them.

- The masking tape can be a temporary fastener, which you need to fix with PVA glue on walls that have been thoroughly cleaned of dirt. It is removed immediately before pouring the screed.

- Liquid Nails. Put in those places of the base where irregularities exist.

How to trim after pouring?

According to the rules of interior construction, after the concrete mixture is cured, the edge tape should extend beyond the surface by 2 cm. Its remnants are cut off with a regular clerical knife.

This procedure must be performed. prior to installation of the finish coating.

Some tapes have special notches, with which you can gently remove all surplus.

What to replace?

Tape damper perfectly performs its main task, differing in its mass of merits. Due to the excellent properties of the base material, for many it is indispensable for other products that need to be used for screed.

However, in the pursuit of cost savings, some craftsmen are trying to replace the edge ribbon with other, cheaper goods. Often, wooden slats wrapped with polyethylene, foam plastic (cut to the required dimensions in the process of use), izolon (soft insulation) become an alternative to the production building (damping) tape.

But each of these budget substitutes has significant drawbacks. For example, the isolon does not differ in excellent sound and thermal insulation properties, since it is porous, and the wooden bars are difficult to fix, they are not easy to work with, and they deteriorate very quickly, because they are subject to fiber breakdown processes. Foam in case of fracture will not be able to return the original form, it crumbles and may break at the most inopportune moment.

It is worth noting that almost all the options with which builders are trying to replace the edge tape do not end in success, which ultimately affects the speed and quality of work performed.

Professional Tips

Demand creates supply, therefore, in the modern market of building materials there is a wide choice of damper tapes from foreigndomestic producers. Products differ in appearance, technical properties and, of course, in price. For this reason, it is quite difficult for many, especially inexperienced masters, to make a choice of one or another tape.

Experts advise for the installation of single- and two-layer screed to buy damper tape with a width of 100 mm. For precast systems, purchase products with a width of at least 150 mm with a separator.

In the process of buying material to pay attention to the model with a marking line, designed for more comfortable and convenient cutting off excess parts.

You can find out how to install the damper tape correctly in the following video.