What should be the minimum floor screed thickness?

In the process of building a house, repairing a new building or finishing in a secondary housing, the question of a floor tie device is necessarily raised. What are its features, what types of floor it is used for, what is the minimum thickness of the layer, will be discussed in this article.

Functional purpose

Screed - this is the first stage, which draw attention to the repair. The quality of its device often depends on the entire appearance and reliability of the room. It is impossible to lay a flat floor and safely place the furniture without having a solid, solid and durable base.

The main functions of the screed:

- It is a draft layer for the finishing coating of various types: laminate, linoleum, boards, tiles.

- Levels the basic basis (concrete, wooden and another).It can reach significant irregularities, differences and have various defects. The screed allows you to smooth them all and guarantee a long life of the floor.

- Provides uniform dynamic and static loads on the floor, increasing their service life.

- If there are technological slopes in the room (for example, in the bathroom to facilitate the discharge of water and not falling into other parts of the house), then using a screed is the easiest way to ensure them.

- Certain types of screeds are stacked to provide enhanced sound insulation and heat preservation.

- A warm floor is installed in the screed, various communications are hidden if necessary.

Device

Which screed you choose, what other layers will be present in the flooring depends on the purpose of the room and the type of house (private, apartment, technical room, brick, wood).

Not so long ago were popular screeds, consisting of a layer of homemade cement mixture. People mixed cement with water and sand, the resulting solution was poured into bases in apartments and houses. There are a lot of disadvantages in this method. The tie is heavy, it may have too strong roughness. Drying time is long, in violation of the proportions of the mixture, poor-quality cement, temperature and humidity changes in the process of drying the cracks are guaranteed.

Currently, cement mixtures are also used, but mainly in the process of manufacturing multi-level screeds. But there are many modern materials for flooring.

In stores, screeds are sold in the form of bags of powder. There are both rough and fair coatings. First, it is diluted with water according to the instructions of the draft layer, poured and dried. It is already imposed thin finishing. Special plasticizers and additives are added to the mixture in order to increase their strength and reduce drying time.

If in the case of a conventional thick cement mixture, the coating can dry for more than a month, then modern powder screeds will dry for several days.

Another advantage of some commercially available powder blends is that they do not need to be leveled. You pour the solution onto the floor, and it itself forms a flat surface.

Shop screeds are made on the basis of cement and gypsum. In the first case, the coating can be laid in dry and wet rooms.Gypsum mixtures are more environmentally friendly, they let in air, but they can only be used for dry rooms.

Both single-layer and multi-layer screeds are preferably applied to the waterproofing layer. It is made by coating with bitumen mastic, special formulations or roofing felt.

If the screed is laid directly on the base without any gaskets, then it is considered bound. The advantage of this draft layer is its ability to withstand the load. But in the process of solidification, the layer can shrink in places. And if your apartment is located on the ground floor, or repairs are made in a private house with a wet basement, then moisture vapor can influence the strength of the screed through the bases.

If between the slabs and the layer of the subfloor there is still another layer, it is usually laid with plastic wrap or bitumen paper.

It is very convenient to assemble a coupler due to the fact that no wet jobs. Separate parts with a dry backfill are connected in a special way. The layer is often quite impressive, and a good sound and heat insulation is achieved. Overlap sheets GVL.You can install the topcoat immediately after the installation of the screed.

If you need to warm the room and protect it from moisture, you can lay a floating screed. Its meaning is that it is independent and does not come into contact with the surfaces of the base and walls.

The substrate is usually a waterproofing layer, for example, polyethylene film, as well as sheets of fiberboard, mineral wool or polystyrene. They isolate moisture, retain heat and perform the function of sound insulation. On each side the coupler is separated by a damper tape. The main layer consists of a conventional cement mixture, reinforced for greater compressive strength.

According to the physical state, you can distinguish different types of rough coatings:

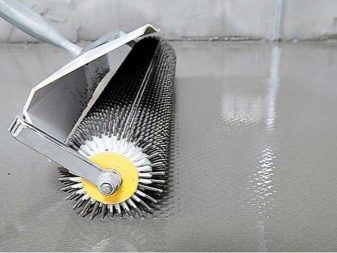

- Liquid. A water solution of cement-sand or concrete mix is diluted. This method is resorted to, if there are significant drops at the base, and they need to be leveled. In the mixture can add expanded clay of different fractions. The layer is filled and aligned with the rule. After drying, it is best to place a self-leveling floor on it for greater smoothness.

- Semi-dry. The solution is kneaded, as in the previous case, with water. But use it to a minimum.And the mixture is very thick. Her spread and leveled. Physically, it is quite difficult to do, but if you do not want to waterproof the floor, then this is the best mix to protect your neighbors from leaking.

- Dry Now this method is very popular. As filling use expanded clay or vermiculite. Cover it with sheets GVL, connecting them together and sizing seams. The floor gets warm and carries heavy loads. Plus fractional materials are quite budget and do not transfer a significant load to floor slabs, although they have a thick layer.

Primary requirements

When installing the screed must meet certain requirements:

- First of all, you should thoroughly clean the base, examine it and assess the condition. It should not be chipped and cracked. If they are present, seal them. Smear the defects with a primer, and then fill it with a regular cement mixture or special repair compound. This will save you not only from flooding your neighbors, but also guarantees the strength and durability of your floor.

- If you pour a screed on a waterproofing layer, then the walls should be covered with this layer by 10-15 cm in height.

In case of using continuous liquid or semi-dry screeds, it is necessary to lay a damping tape on the wall. She will act as a compensator for deformation due to expansion.

- All work related to dilution with water must be performed at positive temperatures. Preferably above 3-5? C. At lower temperatures, the reliability of your design will be a big question.

- The tie must always be complete and uniform. Defects and different thicknesses will lead to an uneven distribution of the load and the destruction of both the finishing and the roughing layer.

- If you work with a wet screed, be sure to withstand the recommended drying time for each type. After that you can start finishing work. Pay attention to the height of the cast layer. The larger it is, the longer the screed will dry. You can check it by putting polyethylene on the floor and crushing it with something. If after a day it forms condensate, then your layer is not yet dry.

- If your room (for example, in the bathroom) does not have a special slope, then there are recommendations for deviations of the curvature of the floor. The SNiP allows the draft floor used for laminate, linoleum and parquet to deviate by 2 mm for every 2 m. If you are laying carpeting or something else, then 4 mm for every 2 m.

- When installing underfloor heating, remember to put a layer of polystyrene under the screed. It is better to give preference to penoplex. It is stronger, and heat insulation performance is higher.

Minimum height

There is no single recommended layer height for the screed. From the correctly selected thickness depends on the service life of the flooring and the reliability of the whole structure.

In general, choose the height of the layer depending on:

- type of room;

- ground;

- maximum loads.

The minimum height for the screed is 2 cm for self-leveling compounds. Starting from 4 cm you need to reinforce the layer under high loads. If they are not provided, the monolithic tie can be laid up to 70 mm.

If you make a coupler less than these values, then the meaning in it just disappears. Sex will be fragile and short-lived. Minimum values should be used in rooms with a small load. The apartment has living rooms. Bathroom, hallway and kitchen require a more impressive fill.

The maximum height, as practice shows, can reach 15-17 cm. Large values are no longer feasible and will be a waste of material.

The screed layer also depends on its method of manufacture.Cement-sand mixture should be covered at least 40 mm high. In the case when you equip a water-heated floor, you need to layer above the construction of pipes. It is recommended to pour a layer of sand concrete 8 cm. In case of adding plasticizers, the mixture consumption can be reduced, as well as the layer thickness.

If you plan to lay tiles on the warm floor of the pipes, then the level of the screed can reach 1-1.5 cm above the structure. Because the top will still be quite a thick layer of tile glue. If you are staying on a wooden floor or laminate, you can use the same rule.

Electric underfloor heating is covered with a concrete mixture of not more than 5 cm. In cases with apartments on the first floor or private houses, the layer can exceed 10 cm. But too thick screed can also become a minus - heat losses will be high, and the floor will lose its heating function.

Floating screed is usually at least 5 cm thick. Using a semi-dry screed on an insulating layer of film allows a thickness of 2 cm. If the substrate is made of expanded clay or expanded polystyrene, then it is worth laying the mixture at 4 cm minimum.

In the case of dry expanded clay ties, a layer height of less than 10 cm is impractical because it will not perform the function of thermal insulation. The thickest layers of the cement mixture are poured when the roughing screed is combined with the foundation, say, in a private house.

But it is better to always use reinforcement for structural strength.

Coupler for different types of floor

When you are thinking about choosing a screed, you need to consider what type of floor will be laid layer.

In apartments, the most common types of flooring are laminate, parquet, linoleum, flooring. Such floors require minimal curvature deviations. Accordingly, the concrete screed, and even more so the coating with granulated particles, will not be able to give the necessary smoothness and evenness.

In this case, you should put a layer of leveling mixture on the rough base of cement concrete.

It is necessary to give preference to self-leveling powder products, widely represented on the market because of the convenience of its use.

In the bathroom and in the kitchen, the actual coverage is tile or granite. In this case, a perfectly flat screed is not required. Enough coarse draft layer.Minimum deviations can be achieved with the help of tile glue.

Under the heat-insulated floors, an insulating layer (film) is laid first, then it is necessary to avoid heat loss — for this purpose a layer of expanded polystyrene is placed. And then they lay out the heating elements, then pour them with a coupler.

In a private house it is necessary to avoid the penetration of moisture from the soil. To do this, usually arrange a sand or expanded clay pillow in the basement, then it is poured with concrete, pre-waterproofing. Industrial premises, warehouses, garages, workshops can exist only with a draft layer of concrete, since the decorative component is not important here, and only reliability and the ability to withstand heavy loads are important.

Recommendations

At performance of a coupler use recommendations of professionals:

- Maximize all the desired parameters of your screed, depending on the humidity of the room, permissible loads, additional functions of the floor and its durability.

- For each type of material strictly follow the temperature regime and recommendations for mixing solutions.

- Modern mixtures, although more expensive, but give a great guarantee of durability and dry faster.

- If you use bonded coatings, do not forget about priming surfaces for better adhesion.

You will learn more about choosing the thickness of the screed from the following video.