Knauf coupler: advantages and disadvantages

Products of the international innovative company Knauf are distinguished by reliability, economy, quality. Thanks to modern technology, it allows you to translate into reality any ideas, creating beauty and comfort in the room.

Characteristics and features

One of the most modern technologies, which is increasingly preferred when leveling floors, is the Knauf dry screed. After applying this method, you can immediately lay tile, linoleum, parquet, laminate or carpet on the floor.

Knauf dry screed can be used when carrying out repair work both in new apartments and in residential areas:

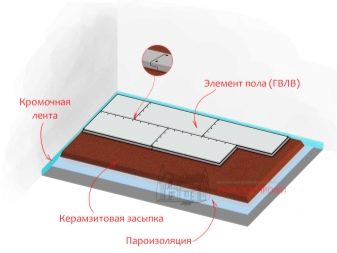

- The mixture usually consists of a loose fine-grained substance, most often expanded clay. It is thanks to this component that the best insulating properties are achieved.

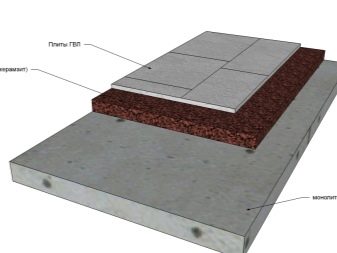

- The second main constituent element of the screed is a solid two-layer coating of gypsum fiber or plasterboard.Inside the layers there is a layer with waterproofing material.

Drywall is a sheet with a lining in the form of cardboard. The coating has sufficient flexibility, it is easy to cut. However, gypsum fiber is often used in prefabricated structures. This is due to the high strength properties, fire resistance, as well as cost. The uniform surface is a mixture of cellulose and gypsum.

Knauf screeds typically use 2 types of sheets:

- Elements of the floor. The design consists of two layers of gypsum fiber, which are water resistant.

- Low-format sheets of gypsum fiber. The design is made of moisture-proof, as well as environmentally friendly materials.

The two-layer sheet design has a slight displacement to form folds over the entire area of the material. Thanks to this feature, sheets can be easily joined with screws and mastic.

The basic principle of laying a dry-combined team is to lay a loose mixture on a substrate of insulating material, which is then compacted under the weight of tightly interconnected panels.

The use of this technology has a number of features that must be considered to obtain the best quality and the desired result:

- The presence of protection of electrical wiring and heating communications using corrugations.

- Wooden or concrete base.

- Normal mode of humidity in the room.

- Exposure to aggressive chemicals is excluded.

- All work is trying to carry out at the optimum temperature of +5 degrees. Very undesirable decrease to minus 10 degrees.

Knowledge of the main characteristics and features of the modern method allows you to decide on the choice of material and properly perform all work on laying screed. Properly selected parameters are the key to quality and durability.

Advantages and disadvantages

Any method has its advantages and disadvantages, knowing that you can avoid many troubles.

The indisputable advantages of dry screed include:

- Lack of long freezing time. The floor can be immediately covered with finishing materials.

- Getting a high-quality surface in a short period of time, which significantly saves time on repairs.

- Lack of dampness eliminates the risk of moisture entering neighboring rooms.

- The method allows to provide high thermal insulation, which excludes the use of additional heat insulating materials.

- Good sound insulation will be appreciated by neighbors.

- The technology provides work without dirt.

- Environmental friendliness.

- Fireproof.

- It is possible to perform work in stages, adjusting the alignment process.

- Durability allows the coating to withstand heavy loads, up to about 350 kg.

- Ease of dismantling the screed.

- The method does not require high qualifications or special skills, which makes it possible to do everything with their own hands.

- The ease of materials and simplicity of technology does not require the use of special heavy machinery.

- The advantage is the lack of strong pressure on the bearing surfaces of the room.

The disadvantages include:

- Cost

- The technology is not suitable for use in damp areas without heating. Any moisture is excluded.

- The alignment layer is large, more than 4 cm, which limits the application of the method in small rooms with low ceilings.

- Severe dustiness during laying.All work is recommended in the respirator and glasses.

- In case of unfavorable microclimate the formation of mold is possible.

Species

There are several types of dry screed, which are slightly different in composition as well as in laying technology.

These include:

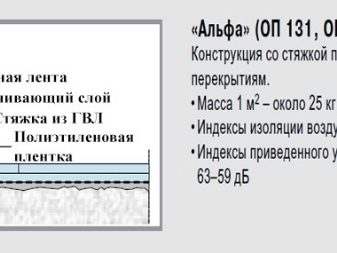

- Alpha screed. Fits on a flat surface. Ground drops up to 30 mm are allowed. It consists of a damper tape, polyethylene, sheets of gypsum fiber. It has a light weight of about 25 kg.

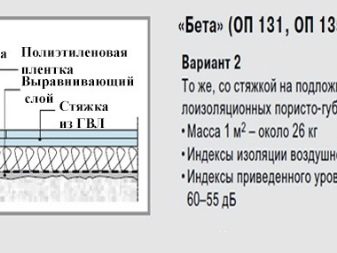

- Betta screed. Also fits on a flat surface. It consists of polystyrene or stone wool, which is a substitute for expanded clay, as well as sheets of gypsum fiber. This type of coating has good soundproofing, as well as high thermal insulation. Its mass is about 30 kg.

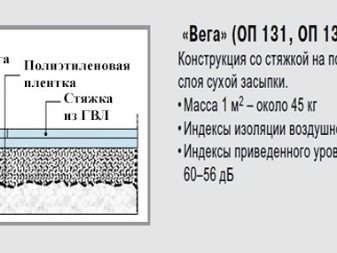

- Vega screed. This type of screed incorporates expanded clay, gypsum fiber sheets, and a damping tape. This coating has excellent thermal insulation, soundproofing, durability. Its mass is about 45 kg.

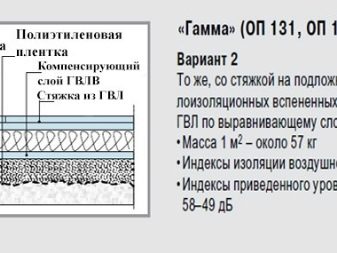

- Gamma screed. Contains clay, durable sheets of gypsum fiber, fibrous insulation. This type of screed has the highest insulation characteristics, strength, surface quality. Its mass is about 60 kg.

Each of the types of screed is carried out in several stages. It should be noted that the greater the weight of the screed, the more stages of its laying, and the more reliable characteristics it has. The lightweight form of the screed is used when the base already has a fairly even and relatively high-quality surface.

How to choose?

The choice of one or another type of dry floor screed should be based on several factors. To begin with, it is necessary to clearly present the final desired result, assess the parameters of the room, its operational properties, microclimate, the presence and condition of adjacent rooms.

It is important to correctly diagnose the baseline, the possible risks.

Next, you should proceed from the timing of repairs, how quickly you need to get the finished surface. Important is the budget that is supposed to spend on laying floors. Quality, reliability, durability depends on it.

In each case, a set of characteristics should be taken into account, and only then be determined with the type of material, additional components.Before applying a method, it is recommended to consult with professionals.

Piling

Before you start work, you must carefully prepare for the repair of floors. So, besides the main components of the screed - bulk filler and gypsum fiber sheets, you will need a polyethylene film in the case of concrete or bituminized paper in the case of wood, as well as a damper tape, edge banding, jigsaw, glue, screws, drill, tape measure, ruler, Screws, putty, knife. Depending on what properties the surface should possess, additional components and fillers can be used.

In addition to the materials and devices with which the work will be carried out, it is important to prepare the foundation.

It should be clean, without protruding metal objects, fittings. If possible, it is better to level the surface with the help of the available devices. If there are gaps, then they will have to close with a putty compound. A primer can also be applied to the surface.

After the thickness of the screed and the amount of unevenness of the floor will be determined, you can proceed to repair work.

The basic rules for laying dry screed include the following steps:

- Polyethylene film flooring is produced with an allowance for walls of about 100-130 mm. This allows to increase the vapor barrier. Instead of polyethylene can be used corrugated paper.

- To preserve the high quality of the appearance of the coating, as well as to compensate for the deformed expansion, an edge band is put along the edges of the walls of the room. In height, it must be equal to or exceed the layer of expanded clay sand.

- In order for the screed to be flat, lighthouses are installed. To do this, apply the rule of tightening the loose mixture in the direction towards itself. In this case, the ends of the device rest against the neighboring lighthouses. Between the lighthouses fall asleep crumb. The minimum coating layer must be at least 30 mm. It is not recommended to fill the base with large portions. This can create inconvenience during the work, which as a result will affect the quality of the final result.

- Then make the alignment of the surface using a slat and remove beacons.

- Further work is carried out on the laying of gypsum fiber material. Sheets are placed in rows, gluing the folds with a special adhesive.Flooring produced with offset. Works begin to lead from the most distant to the entrance door of the wall.

- All glued surfaces fasten with screws. To increase the strength of the joints are treated with PVA glue or connect with screws.

- After completion of the work, you can immediately proceed to the final stage of coating the base with putty and subsequent imposition of finishing floors. (Fig. 1, 2)

Despite the simplicity of the dry screed technology, it is important to adhere to a clear sequence of actions.

Can I lay tiles?

In order to use ceramic tile as a topcoat after laying Knauf screed, you should make sure that the gypsum-fiber construction has sufficient moisture resistance. Therefore, it is recommended to choose only high-quality materials with enhanced protection from moisture. It is also recommended to use additional components that prevent the formation of moisture. In addition, it makes sense to think about waterproofing materials and sound insulation.

Sometimes it is recommended to prime the surface of gypsum sheets before laying the tile.This provides more reliable contact between surfaces, which can significantly reduce the risk of dust, moisture or fungus.

In any case, the use of certain components is solved in each case on the spot. Much depends on the type of room, its location, purpose, operating conditions, temperature. Therefore, in order to obtain the desired result with the lowest cost, it is recommended to consult with experienced specialists. (Fig. 3)

Reviews

Often you can find reviews of those who have already used Knauf screed technology. Users of the dry method share their positive and negative experiences.

So, many say good soundproofing of floors, surface quality, long service life. It should be noted that those who used only high-quality materials and conducted work in compliance with all the rules are quite satisfied with the final result. In the future, they also plan to use only this method for repairing floors.

There are also those who do not like the appearance of such floors, their simplicity, too high a height, as well as restrictions on the use in wet areas. Many are discouraged by the high cost of the method.Often negative experience is associated with the consequences of the use of poor-quality material, which contains third-party impurities. When operating such surfaces, there may be creaking, the appearance of irregularities.

Of course, this technology has its supporters and opponents. This is due to different reasons and preferences. In any case, every experience is useful. It allows you to learn new things, learn the subtleties of the method, possible undesirable consequences, as well as determine the final choice.

Successful examples and options

In the examples you can see what the floor looks like after laying a dry screed.

- In this case, gypsum-fiber sheets are tightly joined with screws. (Fig. 4, 5)

- In these examples, it is clear that gypsum fiber sheets are bonded with glue. (Fig. 6, 7)

- This example shows the result of applying a light dry screed. (Fig. 8)

From the video below you can learn in detail about the Knauf screed and its durability.