Knauf dry screed: the pros and cons

To make the floor even, without a single flaw and defect, professional builders use various methods and techniques to work. However, in the construction market, every day there are more and more new products, with the help of which almost every person can cope with the task of imperfect floors.

The method of dry floor offered by Knauf allows you to create high-quality flooring in the shortest possible time, without unnecessary material and physical costs.

Knauf dry screed is the right solution for creating the perfect flooring.

Special features

Knauf-superpol is German quality, reliability and durability. The technology is a multi-layer construction of gypsum-fiber panels (GVP). The leveling layer is a dry, moisture-resistant backfill in the form of expanded clay sand, the dimensions of which are carefully selected and controlled. Expanded clay backfill allows you to remove almost all the shortcomings of floor slabs (skews, slopes, etc.) and create a perfectly flat base surface for future flooring. Gypsum panels are quickly and easily mounted, and in the process of work there is a minimum of waste.

The popularity of dry flooring from Knauf explains them high quality technical specifications. The floors created with the help of this technology give the owners a feeling of coolness in the summer period, and on the contrary, they warm them in the winter. They do not make extraneous sounds, do not creak, do not crackle, guarantee perfect sound insulation.

Flooring made with Knauf dry screed has an excellent smooth surface, they are aesthetically attractive and durable.

Knauf rough floors are laid during:

- laying of various kinds of floor coverings in multi-storey high-rise buildings, office and commercial premises, in cottages, country houses, hotels;

- restoration of buildings built in the 50-60s of the last century or buildings with wooden partitions;

- if the room is always cold and it is not possible to perform a concrete tie;

- laying of a heat-insulated floor in buildings with overlappings from a tree;

- with minimal timing to create a subfloor.

The dry floor of the Knauf trademark can eliminate various defects and base distortions. The unique “dry screed” technology can be applied to such types of coatings as parquet, tile, laminate, linoleum, however, the folds of linoleum and parquet must be glued with a solution of PVA or something similar.

The advantages of the floor Knauf include:

- the formation of a perfectly flat base of the floor, which can withstand a load of 500 kg / m2, in the point version - 200 kg / m2;

- high refractoriness;

- hypoallergenic (dry fill does not cause allergy attacks in asthmatics and people prone to allergic reactions);

- excellent sound insulation; squeaks and crackles do not occur when walking; no fractures appear during the whole service life;

- optimal thermal properties;

- the possibility of mounting plasterboard;

- operational capabilities (on the backfill you can move immediately after its installation);

- quick installation;

- the ability to create a floor in turn in different rooms without losing a single level of height;

- lack of "wet" processes of construction work;

- the possibility of laying on the top layer of the dry floor of any coating: porcelain stoneware, tile, laminate, wood flooring, linoleum.

But, despite the obvious advantages, the dry backfill of Knauf has its drawbacks:

- low moisture resistance. If moisture for any reason gets on the floor, you have to open the entire structure to dry, and in some cases there is a complete replacement of the coating. Therefore, a dry screed should not be used in the bathroom and in the kitchen, where there are temperature fluctuations and quite often increased levels of humidity if warm water floors are created, in unheated or poorly heated and basements;

- high degree of dustiness when filling the expanded clay crumbs. A respirator must be worn during construction;

- higher cost compared to other types of flooring;

- high height subfloor. It is not always appropriate to use the dry screed method, especially when the ceiling height in the room is not sufficient to perform such work.

Composition

Knauf floors are called differently: dry screed, dry fill, superfloors. However, all this is a combination of different materials that are used in the installation of a rough tie.

Dry screed is a composite composition of the following elements:

- Vapor barrier. A thick PVC construction film that is laid on the floor slab to prevent unwanted moisture penetration. If you use it on hardwood floors, you can avoid accidental spilling of expanded clay granules into the gaps between the boards.

- Edging tape. It is used for additional sound insulation. Absorbs the sounds of human footsteps and other possible noises. Lay it over the entire area of the room between the screed and all the walls.

- Dry fill. The most commonly used claydite sand with a fraction size of not more than 5 mm. For backfilling, materials such as perlite, quartz sand, fine-grained slag, etc. are also used. The dry mix evens out the base of the floor, smoothing out all irregularities, pits and slopes. The minimum thickness of the dry-fill layer should be at least two centimeters.

- Interconnected moisture resistant gypsum fiber sheets Size 120x60x2 cm. Produced at Knauf factories and used in draft floor systems. When creating a dry screed, they are lined up on filling, they are coated with PVA construction glue and fixed with self-tapping screws.

- PVA glue. A white solution with a specific odor is used for bonding Knauf floor elements (GVL). Glue is applied to the seams of neighboring elements, after which the sheets are additionally secured with screws. Elements of the floor are transformed into a solid and solid foundation.

- Self tapping screws. Special fasteners for gypsum fiber with a head and an external thread. Used when laying dry backfill to bond additional floor elements to each other. In combination with glue, PVA provides high-quality and reliable fixation of floor elements to create a solid base, ready for laying the final layer of the floor covering.

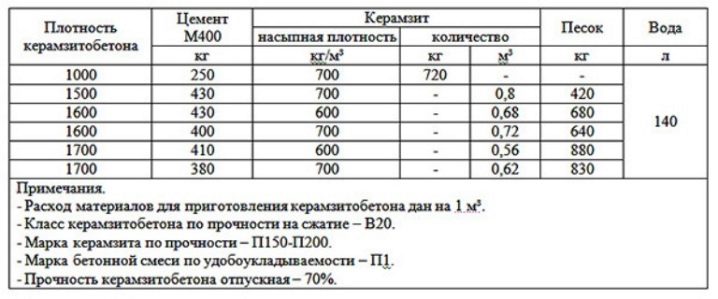

Consumption

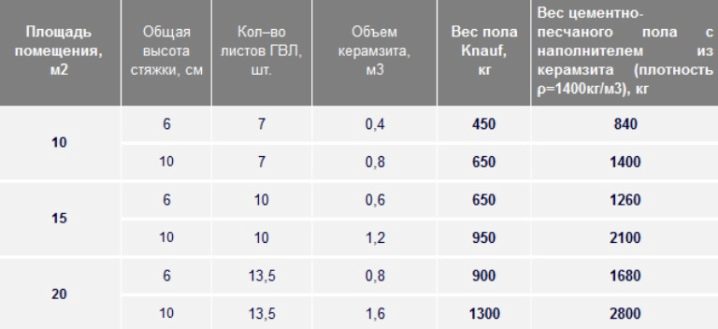

To understand how much dry screed will be needed per 1 m2, it is necessary to consider the following parameters:

- the square of the room;

- selected height of the filling mixture;

- size and placement options for building materials.

For the implementation of installation work will also have to perform the calculation:

- the volume of expanded clay (sand);

- the number of GVL plates;

- the length of the damper tape;

- linear meter PVC film;

- the number of profile rails;

- the number of screws;

- Liter of glue PVA.

First of all, you need to find out what the footage of PVC film needed for waterproofing will be needed.We must not forget that according to the rules, it should overlap by about 20-30 cm and also “fit” on each wall (the length depends on the height of the bulk floor. The film is most often sold in rolls 1.5 m wide. Usually it is double and to expand it, then the entire width will be 3 m.

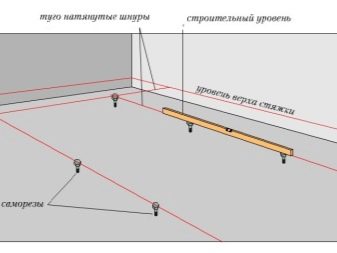

Not every screed is stacked using beacons. If the room is small, you can do without additional markers. But thanks to these elements, leveling the backfill layer is much easier.

Profile bars are available in 3 m length, because in the room of a typical multi-storey building they are placed across the room, one meter from each other. With this placement, the number of profiles is determined based on the length of the room with an additional one rail.

To find out how many GVL will be needed, you need to calculate the floor area and, focusing on the dimensions of the plates, determine their desired number.

To calculate the consumption of expanded clay crumb, you need to decide in advance what backfill thickness will be used, taking the average figure as a basis, which is especially important when there are drops in the base of the floor. The average thickness is determined by the maximum and minimum point of its height.The volume of expanded clay is then set by multiplying the quadrature of the room where the work is carried out and the thickness of the backfill layer. Perfectly accurate calculation is not always possible; therefore experts advise to buy expanded clay with a small margin.

The size of the damper strip should coincide with the perimeter of the room, while it is not necessary to skip the width of the doorways.

It is better to buy a tape of a little more length in case it accidentally breaks or other unforeseen situations happen.

The calculation of the amount of PVA glue is quite simple. The manufacturer indicates that 50 grams of glue is needed per square meter of space, therefore, this number should be multiplied by the area of the room and the resulting amount of the desired product.

According to building codes, up to 10 pieces of self-tapping screws, but not less than 6, should be built into each sheet of gypsum fiber. Thus, it is very easy to calculate the total number of fasteners.

Minimum thickness

The thickness of the backfill of the dry mix for the floor depends on the quality of the surface of the floor itself (the number of irregularities and other defects, the size of the slope),as well as on the presence and features of engineering communications.

As a rule, the thickness of the layer ranges from 30-50 mm.

Laying technology

Knauf dry screed is carried out in several stages:

- Preparatory work. Completely removed all the old finish, after which the surface is examined for the presence of flaws. If defects are found, they need to be filled with cement-sand mortar in a ratio of 1 to 3.

- Waterproofing. It is necessary to estimate the amount of work to be done, depending on the installed humidity in the room. The minimum that you have to do is to cover the entire floor with a film, fix the seams with adhesive tape, and then put a damper tape around the perimeter of the room (if it does not have a glued side, you can grab it with a special building tape).

- Installation of beacons and profiles. Without these elements, it is difficult to fill in the backfill, especially in a large quad room. The slats are laid on the floor (no matter where the work is performed: in the kitchen, in the living room, in the bedroom, in the office or in the factory room), they are leveled by the building level and the rule.

- Backfilling of voids with expanded clay. In order to reduce the number of movements along the surface of the new screed, the expanded clay fraction is started from the side opposite to the door.Such work needs to be carried out both with a wooden floor, and with other types of a floor covering.

- Alignment screed. This process is done by the rule. If beacons are pre-installed, alignment takes place very quickly.

- Laying the floor. By the principle of backfilling, it is made from the far corner of the room to the front door. Knauf sheets are fixed with self-tapping screws.

The main difference between the dry backfill and the wet backfill is the time it takes to complete the installation.

If in the “wet” version, all stages of work need to be done in one day, then with the “dry” version, the work can be divided into several days, a break or even completely suspended for an indefinite amount of time. The exception is the finishing part of the installation, the manufacturer advises to do it. in one day. This will save dry backfill from moisture.

Reviews

Mostly Knauf products, and in this case dry screed, have positive reviews. The advantages of consumers include: the rapid execution of works, the lack of dirt during installation, good noise insulation and the relative warmth of the coating. I also like the fact that you can walk on the floor immediately after its installation and it looks monolithic compared to a concrete screed.

However, there are negative remarks. Buyers note that if the floor was accidentally damaged (a small amount of water got into the structure), a mold could form under the floor system. This means that you have to dismantle the entire coverage or install a new floor, and this is fraught with large financial costs.

They also say that if linoleum is lined on the floor, then heavy cabinet furniture with legs can push through GVL plates, and the sharp heels of women's shoes can leave visible dents on the floor, which will spoil the aesthetic appeal of the floor covering. At flood the screed dries very long, and there is no certainty that it will dry at all.

You will find out how strong the floors made by the Knauf dry screed method are in the following video.