Screed under floor heating: the choice of material and features of the fill

For many years systems of underfloor heating have become in great demand, which have become a substitute for conventional equipment for space heating. Specialists can talk about the various options of the system, each of them has its own characteristics and advantages. Before laying a warm floor it is necessary to examine each of them, but the main task is to choose a screed, as it is the main part during the arrangement of the heating system.

Special features

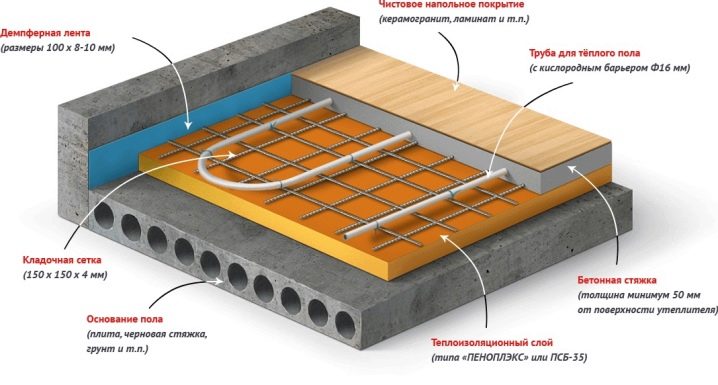

The design includes four layers. Any of them must be made with high quality, so that as a result the warm floor is functional. The basis is the roughing screed, because it serves to even out any defects and repair cracks.This is hard work that requires special professionalism and experience.

But if you follow the main recommendations, you can do it yourself.

If the house was built with slabs, do not have a rough screed, as the coating is almost perfect. Otherwise, you will need a heat insulator - cork substrate. The next step is to lay a water pipe, cable or mats. It all depends on which one of the options you choose. After that, work is carried out with a concrete screed.

What requirements must meet the floor?

The coupler, as is known, is not only a thermal element. It must have other properties. It has a large load, so its endurance and strength matter. In this way, care must be taken to ensure the sustainability of the flooring.

Before laying, qualified specialists always inspect the floor for defects that must be repaired. Any cracks, cracks and irregularities must be corrected, otherwise it will adversely affect the operation of the entire system in the future. Unfair testing leads to breakage of the heating equipment and all elements.

Proper implementation of the screed, the choice of the appropriate design will make everything durable and reliable, and the heating system itself will delight you with a comfortable climate inside the room.

DIY assembly

You can do the laying of the floor heating by yourself. You only need to take the time to study important information, follow step-by-step instructions clearly, and use high-quality materials with tools to facilitate the task. There are many varieties of intermediate coating. Some of them are suitable exclusively for commercial buildings, while others can heat residential buildings.

Wet roughing can be called one of the leading. Regarding the thickness of the coating, it is important to know in advance the volume of the room that affects the cost of the material used. A wet solution dries out for a long time, but this option is more economical than the others.

A semi-dry screed is preferred among professional builders. This coating is intermediate. It consists of sand, water and concrete. On such a screed is perfectly laid laminate flooring, as well as flooring and ceramic tiles.

As for the dry material, it uses a composition of different mixtures, which must be evenly distributed throughout the area. Then dense plywood sheets are used, sometimes concrete blocks. We must not forget about the use of insulating materials on which the coating is installed.

If you decide to engage in laying yourself, but do not have enough experience, it is recommended to use a ready-made self-leveling roughing mixture, as the bulk is bulk. She lies down without additional help. This method is suitable for filling the floor in apartments.

The height of the coating is determined independently. It all depends on individual requests. It is better to consult with professional builders.who can recommend options as well as direct you back on track. To keep the floor level low, take a bit of the mix.

Features semi-dry screed

To install a heated floor, it is important to choose the type of installation. Semi-dry is in demand among specialists, because with it you can choose any thickness of coating, although it is important to carefully examine the other indicators:

- If the installation is thin, defects may appear over time, and this will adversely affect the operation of the heating components.

- The thick construction is great for a system that functions on water or electricity.

Wherein focus on buying quality materialsso that in the end everything worked out in the best possible way, and the heating pleased you for many years, and you also did not have to do repairs, since these are additional costs and efforts.

To make a semi-dry screed, you need to choose a special series of concrete and sand. Check if the manufacturer intends them for drafting procedures. And here it does not matter if you want to make a warm water or electric floor. This mixture copes with temperature changes, is stable, and these are the main advantages.

It is important to ensure that the material is not plastic. The solution should look like wet sand. To evenly distribute the mixture over the surface, prepare a trowel or spade in advance.

It will take a day for the screed to dry completely, so leave a covering for this time, and do not enter the room. Only two days later you can do laying tile or laminate.

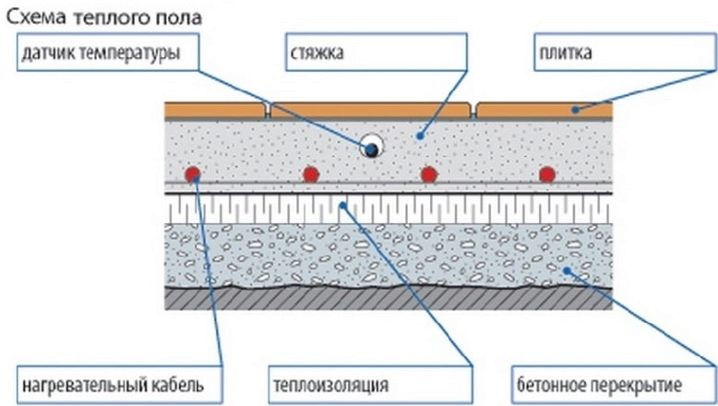

Installation for electric heating

Take into account the minimum thickness of the screed, which is located above the heating cable (and under it). There are several ways of installation. It is necessary to prepare a solution, and after that engage in pouring the surface.

Careful implementation of all the rules will help avoid cracking the coating, and the heating will be the same throughout the room, and the system will last for a long time.

How to choose a screed layer?

The surface must be perfectly flat before laying the cable, so it is necessary to fill the screed with a thickness of at least 3 cm. If you decide to use an investment mixture, you can make it a little thinner. Such indicators depend on a number of factors.

Pay attention to the dimensions of the foundation for pouring, and it is equal to 10 cm, so follow this indicator to the surface was perfect.

The coupler for the electrical system is selected individually. This is indicated by many experts. Everyone has their own opinion on this matter, so it is better to refer to the recommendations of the manufacturer of mixtures, to study the features of the products in order to find a suitable option.Before using any materials that are part of the screed, you need to know about the main indicators and operating rules.

Reinforcement

Each stage of laying a warm floor requires a responsible approach and a serious attitude. To avoid the occurrence of cold zones on the coating, it is necessary to make sure that no cracks or other defects appear in the future. In such cases, the reinforcement is made, which can be done in different ways.

Fiber fiber will be needed for the solution, since it performs the task of adding and polypropylene plays the main role. As a result, the amount of soil will be increased a couple of times, and the strength characteristics will improve. Thus, the result will be positive, and you protect the coupler from sedimentation and other damage.

In the course of work, it is necessary to use a special grid, which is also selected according to the corresponding parameters.

Fill rules

Since everyone wants to achieve the desired result, it is important to follow a special technology so that everything is done with high quality. An important part of the work is preparation, during which the cable unfolds when it comes to an electric field.Qualified professionals use beacons to achieve the smoothest possible surface. They need to place on the perimeter, stretch the line, and then use the elements. If done correctly, you will see a great result.

The initial layer is placed in 3 cm. After a day, the mixture is poured again to pull off along the beacons. Observe the boundaries, and do not go beyond the edgesotherwise, pits will soon appear on the surface. The screed dries a few days, it must be protected from direct sunlight.

This technique is relevant among professional builders. During dry screed, they use certain elements, including a film to protect against moisture. This solution is great for wooden floors. To provide sound insulation, the edge band is required, and for leveling the layer there is a dry backfill.

Now you have learned about the basic rules for the choice of screed, and the principles of installation. You can do the installation of a heated floor on your own, or you can entrust the work to the hands of craftsmen who will do everything quickly and efficiently. Choose the best mix option (for example, firms Knauf), paying attention to the recommendations of the manufacturer, and let your repair will end with success, and you will be satisfied.

You can learn more about how to make a screed floor.