Ways to install beacons for floor screed

The installation of beacons is necessary for almost all methods of floor screeding. This is done to ensure that the finished surface turned out perfectly flat and strong. There are several types of lighthouses that can be both special reusable and disposable from scrap materials. Installation methods are several and suitable is selected, depending on the composition of the solution to be poured and the characteristics of the room.

In order to correctly select and install beacons, we will consider in detail their features and installation technology.

Design features

For self-leveling floors, lighthouses may not be necessary, but only on condition that the leveling layer is no more than 3 mm thick.A thin layer of such a mixture independently spreads over the entire surface into an ideally horizontal plane.

Screed of concrete and cement-sand mortar does not spread independently and must be leveled. In this case, lighthouses act as original guides along which the leveling process takes place.

Beacons are divided into two main types of installation method:

Spot setting

Designs for alignment are set at an equal distance from each other, usually without interconnecting. It is quite difficult to work on such beacons without proper practice, therefore, as a rule, they are used among experienced specialists.

- Reper Beacons. This is a kind of tripod, in the center of which there is an adjustable screw-in rod. The races are leveled among themselves on a flat top platform with the help of a building level. The bottom of the rod thus indicates the maximum height of the poured layer. Frame beacons are most often used by professional builders for building self-leveling self-leveling floors with a layer thickness of 3 mm. It is also possible to use them to perform screed based on dry mixes.For all other types of solutions, tripods are not suitable.

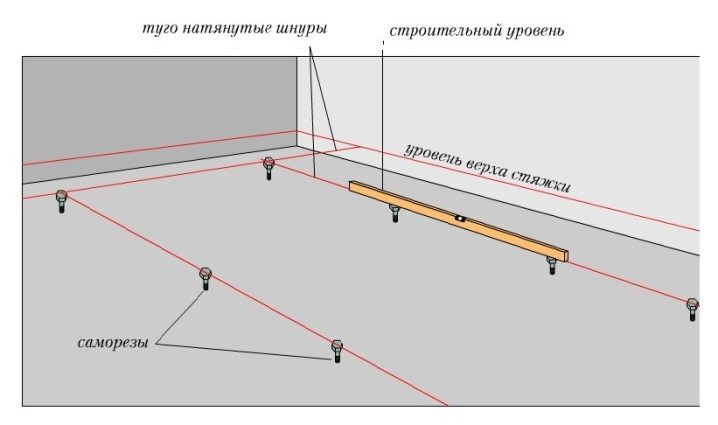

- Screws and dowel-nails. As beacons, they are twisted into a concrete base; if necessary, a thick fishing line or wire is stretched between them. Height adjustment is performed using the building level. Used for leveling self-leveling floors. After completion of work, it is recommended to remove them from the dried layer.

- Mortar cones. From the composition, which will be used for flooring, small slides are made at equal distance from each other. The upper part of the slides is cut by the rule for the level of the future screed. The solution will set and become durable in 2-3 days, then you can start laying the base layer.

Instead of a concrete solution, quick-hardening putty mixtures can be used. They dry faster, and the work can be started the next day. Gypsum-based blends are not recommended, as they are often incompatible with screed solutions.

Linear installation

Linear beacons are placed along the length of the room from one wall to another. The width of the space between the beacons should be ¼ shorter than the rule by which alignment will be performed. Compared with the point, this method is more simple and convenient.Even a novice can cope with a screed device according to such beacons.

- Aluminum T-shaped or U-shaped profile. Plasterboard kits are used with a screed thickness of 3-5 cm. Plaster kits are softer, so they are only suitable for mortar with a layer up to 1 cm. It is necessary to work with such guides very carefully, aluminum does not have strength characteristics and can bend during leveling. U-shaped profile is convenient to use for dry screed. Such beacons are usually not removed from the solution after laying. In general, this does not affect the strength of the finished surface. But if the protective layer of the profile is damaged, over time it may rust and cause deformation of the screed.

- Wooden slats. Recently, as a beacon tree is used extremely rarely. This is not the most convenient material. Its surface may not be sufficiently smooth, and the material itself must first be soaked in water so that it does not take moisture. Wooden lighthouses must be removed from the set solution.

- Steel pipes of any section with a diameter up to 7 cm. Great for leveling a large layer of concrete mortar screed. At the same time, rectangular or square pipes give a smoother result and are easier to remove.Steel pipes must be removed from the set mortar.

- Mortar beacons. Just as the slides are laid from the solution, which is used to make the floor. To do this, a dowel-nails are screwed into the concrete base, and a thick fishing line or wire is pulled over them. Alignment is done by adjusting the height of the screw using the building level. The solution is laid out on the resulting construction and carefully leveled, forming a strip with a flat upper platform.

The main work on the floor can be started in 2-3 days. Mortar beacons are more difficult to install, but it is more convenient because after the solidification of the screed they do not need to be removed.

- Dry screed slats. Such lighthouses are not attached to the floor, but are simply laid on a loose filler, which is usually used as expanded clay or polystyrene chips. After leveling, the slats are simply removed. Due to this variety of lighthouses, you can buy any material you like or use various improvised accessories. The main task in arranging the screed is to correctly set the level indicators.If you determine the flatness of laying only "by eye", the end result may not be happy.

Which is better?

The choice of beacons mainly depends on the mortar from which the floor screed is made:

- So, for self-leveling floor it is better to use beacons-rappers.

- Self-tapping screws or dowel-nails are less convenient, but they can be used in the absence of special beacons.

- Slides from the mortar solution for the floor are not suitable. They are used for screed concrete.

- Cement-sand mixture and concrete mortar spread only on the linear structures of the lighthouses.

The material for the beacon is selected, depending on the thickness of the layer of the screed. Aluminum profiles are suitable for a layer of up to 5 cm, and a layer of up to 10 cm is aligned with the beams of steel pipes.

For dry screed methods, you can use any linear beacons, but it is more convenient to use the U-shaped profile of aluminum, which is laid with sharp edges up. After leveling the dry filler beacons do not need to be removed, this will give additional rigidity to the structure.

Installation technology

To work on the equipment of the beacons will need the following tools:

- construction or laser level;

- tape measure or long ruler;

- pencil or marker with a thin rod;

- cement mortar or bolts for fixing the structure to the floor.

In order for the floors to turn out even, and the consumption of materials was within reasonable limits, the indicators should be set on the correct horizontal plane.

To do this, first find the point of the floor, which will be the highest in the room. The height of the screed in different rooms should be different, depending on the selected finishing flooring so that when moving between rooms there are no steps. The exception is the bathroom and toilet, where the floor level is required belowthat will not allow liquid to leak out when water supply and sewage pipes break through.

For work, you will need a normal construction or laser level and a tape measure.

Procedure:

- It is necessary to mark with a laser or draw a horizontal line along the perimeter of the walls along a bubble level with a pencil. The length of the segment from the floor to the markup should be about 1 meter.

- A long ruler or tape measure makes measurements of the distance from the line to the floor at several points along the wall.The smaller the step between measurements, the more accurate the obtained result will be. Instead of a ruler, you can use a profile or rail, which indicates the desired distance.

- Point, the distance to which will be the smallest and will serve as a guide when installing beacons. Usually this point is located at one of the walls or in the corner. From the obtained value you need to subtract the thickness of the tie and on this height draw a new horizontal line. Before this line, the screed will be laid and it must be oriented when installing the beacons.

According to the linear type, the beacons must be placed along one of the walls of the room so that the distance from the wall to the lighthouse is 10-30 cm. The distance between the beacons should be a quarter less than the length of the rule, usually it is 75-100 cm. If the room is too large in size and it is impossible to perform a screed in one day, it is divided into several sections with solid beacons. At the threshold of the room is also recommended to put a solid beacon or a fence made of plasterboard or wooden bar.

Aluminum profile beacons can be fixed to the floor with screws or bolts. But if the layer of roll waterproofing is arranged, the fastening is possible only on cement or gypsum mortar. There are some limitations on the use of gypsum mortar.It can not be used in rooms with high humidity, and it is often not compatible with various solutions for floor screed. therefore it is better to give preference to cement or cement-sand mortar. Pipes are mounted only on such a solution.

Along the line of placement of the lighthouse at an equal distance from each other are placed slides of the solution, they are exposed profile or pipe. With the use of a laser level or cord, stretched across the placement of beacons, alignment occurs. Pipes are pressed down to the floor or raised by placing pieces of broken bricks.

Horizontal constantly need to be checked by level. both in relation to the mark on the wall, and between the lighthouses. The solution dries for 2-3 days, then you can proceed to the device screed.

Be sure to pay attention that the cement-sand and concrete mortars are stacked with a layer of at least 3 cm. If the layer is smaller, it will quickly crack. If a thinner layer is needed, self-leveling self-leveling floors or special dry mixes are recommended.

Preparatory work

The lighthouses are installed directly in front of the device for the tie, therefore, you must first prepare the room:

- Repair walls, windows and ceiling. All repairs, except wallpapering and installation of interior doors, must be completed before screed work.

- Make a thorough cleaning of the room. Concrete base must be removed from the old flooring. During further work in the room should not be dirt, dust and debris.

- Remove the baseboards, doors and door slopes.

- The base for the screed must be fully prepared. To do this, get rid of grease stains, paint and glue on the floor. Grind the surface with a sanding machine and primer in two layers. Cracks and chips on the concrete base must first be filled.

- If a waterproofing or reinforcing layer is to be laid, the installation of a underfloor heating system is required, all these manipulations are also carried out before the installation of the beacons. But a layer of insulation is usually recommended to lay between the installed beacons.

For dry mix

For dry screed, it is better to use a U-shaped aluminum profile.Its exposure to the floor is carried out with the flat side down so that the sharp edges are directed upwards. Fastening to the floor is possible both on screws, and on a solution of plaster or cement. Height adjustment is made to the desired line using the level.

Expanded clay or other bulk material is filled up not only between the profile, but also inside it. This creates an additional effect of noise isolation. The material is leveled between the lighthouses by the rule, the surplus is removed. This method of screed is convenient because the material is laid immediately on the claydite and lighthouses and no need to wait for the solution to dry.

Instead of the U-shaped profile, you can use slats, which are simply laid out on top of expanded clay. After leveling, the slats are simply removed from the surface.. In this case, the screed sheet material lies directly on the bulk materials.

For self-leveling floors

If the self-leveling floors rise to a layer of more than 3 mm thick, then for the correct pouring it is necessary to set the beacons. Using the instruction, the beacons-rappers can be correctly installed and configured by hand. The preparation of the base and the marking of the highest point of the floor takes place according to the same principle as for a conventional screed.

Floating device is not recommended for self-leveling floors, that is, the use of roll materials for waterproofing. On them, the bulk layer will quickly crack or deform. Frame beacons are installed at a distance of about 1 meter from each other.

The setting is as follows:

- A construction level is placed on the upper platforms of two adjacent bench marks.

- With the help of a special bolt, the central rod is set along the line of the highest point of the floor.

- By the same principle, neighboring beacons are tuned.

At the threshold you need to install a limiter, so that the mixture does not flow out of the room. The solution is poured into strips and leveled with a rake or spatula on the bottom scale of the beacon. At the end of the work, the surface is rolled with a needle roller, and the benchmarks are pulled out, leaving no traces.

It is not recommended to use plastic frames, which are small rulers on the stand. They are pulled out only after solidification of the layer, and the remaining hole will need to be filled. Instead of beacons, rappers, you can use screws or dowels-nails. To do this, they are screwed around the perimeter of the floor, and in the process of pouring on them the mixture is leveled. Screws are unscrewed only after solidification..

How to install beacons for floor screed, see the following video.

Professional Tips

In order to perform all the work with high quality, it is not forbidden to use the advice of professionals:

- Beacons are recommended to be taken out from the dried-up solution. This eliminates the likelihood of rust and deformation.

- The beacon can be removed from the concrete solution only if there are no footprints on the surface.

- Frame beacons should be used only when building a self-leveling floor. In all other cases, it is better to use linear constructions.

- Wooden beacons for ease of extraction should be treated with waste oil or liquid soap.

- Concrete solution between the linear beacons need to pull not only on themselves, but also to make the rule of movement in hand.

- After building the screed at several points on the floor with a building level or rule, check that the surface is even. The dimensions of the gaps should not exceed 4 mm.

- If the concrete or cement-sand surface is not flat enough, you can pour a layer of self-leveling mixture on top.

- With a laser level, measurements will be more accurate.