How to choose a warm floor?

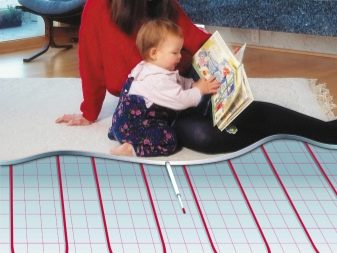

The components of comfort in the house everyone understands in his own way. But there is a basic list of conditions that make the house cozy, and the warm floor in this list is among the first. This useful device is necessary so that the flooring is pleasant for walking barefoot at any time of the year, the room temperature remains comfortable and the risks of colds are reduced. This is especially true in areas where it is impossible to lay carpets due to allergies and in homes where there are young children, because most of their games take place on the floor.

A natural question arises: how to choose a warm floor? It is easy to do this by examining all the features, advantages and disadvantages of different types of floor heating systems.

Special features

Heated floor - a relative novelty in the domestic market. Currently, this is no longer a luxury, but a means to make your home more comfortable and pleasant to live using modern technologies. But a few decades ago, due to the high cost of equipment and installation, it was considered affordable only for the elite class housing. Hence, today's consumer has so many questions about how it works, which one is better to choose a heated floor and is it safe to use.

Different types of floor heating systems have different performance characteristics. Their working principle, methods of installation, technical characteristics differ. The price range of the system and installation work is different. But it unites all types of warm floor with a number of inherent features:

- The method of heating the room. Comparing the thermal profile of centralized heating (radiators, batteries in an apartment or house) with the profile of a heat-insulated floor of any type, it is easy to notice the difference in the methods of heating air in a room. In the case of radiator heating, there is a loss of heat away from its source.The temperature difference in one room near the radiator and at the opposite end of the room can be 7-10 degrees. The farther from the radiator, the colder.

Heated floor gives off energy evenly, warming the surface of the floor covering. Thus, the warm floor provides the correct distribution of heat in an optimal way for the body: at the feet is warmer than at the level of the head.

- The ability to regulate the microclimate in room. Heating systems for the floor are equipped with control units. Thermal sensor, regulator, servo - these are useful system components that make it possible to use a heated floor at any time of the year. It is not necessary to wait for the heating season - if the weather is not in the right season, you can use the system when necessary. You can also independently set the desired temperature to which the system must warm the floor surface. Most models provide for automatic switching on and off of the system, which heats the temperature to a given parameter, then turns off when it reaches it, and the cycle repeats from the beginning.

- Right and useful investment. Few people do not try to save the family budget, and the warm floor, especially the last generation, is designed so that it ensures maximum energy efficiency of the system per 1 m2 of space. Yes, the system itself and its installation can be costly, but they pay for themselves very quickly.

- Features of the device system. If you compare the smartphones or laptops of two generations following each other, the representative of the latter will be more compact. This is the trend for all smart appliances, including floor heating systems. If ten years ago for its installation it was required to mount the structure up to 20-30 centimeters in height, then the last-generation warm floor takes no more than 5 millimeters from the room height.

This is achieved by changing the internal structure of the system: heating and conductive elements are becoming more compact, protective and reflective layers are thinner.

Advantages and disadvantages

Heated floor, especially in apartments on the first floor and private houses, is popular due to the impressive list of advantages. Each type of warm floor, they are slightly different from the others, but common The advantages of all varieties are:

- Heated floor contributes to a more uniform distribution of heat in the room without overdrying the air.

- It can replace all heaters and heat fans, which create convection of heat flows in the room, which also leads to stuffiness and uneven heating of air layers.

- Static electricity is not generated.

- Gives you the opportunity to walk barefoot. This fact is pleasant in itself, but its real the benefits are in the beneficial effects of barefoot walking on the body:

- Prevention of flat-footedness, clubfoot and foot developmental defects in children and adults. Proper formation of bones, muscles and ligaments of the feet;

- The risk of fungus, flaking, corns and corns is reduced, as the skin, relieved from sweating in slippers and socks, remains in a healthy state;

- Blood circulation is stimulated, and consequently, the body tone and emotional background increase;

- Pleasant tactile sensations help to develop the nervous system;

- The ability to control the temperature in the room to the degree.

- Simple and clear operation of automated modern systems.

- Heated floor - a convenient place for children's games, charging and exercise.

- The system is combined with different types of finishing;

- If there are allergies in the house, the heated floor will eliminate the eternal dilemma - a synthetic carpet that does not cause allergic reactions and has no other advantages, or a harmful, but natural quality.

- Heated floor can be installed in rooms of any type, from children's bedroom to the bathroom.

- Some types (for example, film infrared floor) can be mounted not only under the flooring, but also on the walls and ceiling.

- The heating system for the floor eliminates the common problem in the apartments on the first floor - the cold rising from the bottom. The floor of all the upper floors is much warmer, since this is the ceiling of the neighbor's apartment, but on the first floor it is as close as possible to the ground and the foundation and is the main source of cold in winter.

- Manufacturer's warranty on almost any system - from 10 years.

You can not ignore the disadvantages inherent in most varieties of warm floor:

- The requirements for the condition of the subfloor on which the heating will be laid are very high, as are the requirements for the quality of the material for finishing the floor.It is important to take into account its thickness, composition, and the presence of special markings, and all operational characteristics.

- Moving from the premium product category, floor heating is still a costly pleasure. There is an accompanying disadvantage - a large number of fakes and unscrupulous manufacturers.

A poor-quality system will cost much less, but the safety of its use is a big question. In addition, the service life of such a system is very limited.

- The question remains unclear whether the warm floor can replace the centralized heating or it can only work as an additional source of heat. Many manufacturers claim to be capable, although in reality this turns out to be wrong.

The exceptions are just a few options. The first is the use of warm floor as the main source of heat indoors in the warm regions of the country, where the mild climate and the “European winter” prevail. The second is to lay products under the floor that take into account the climatic features of cold regions and operate at higher power.

- Electric heating systems, even the most modern and intelligent, can not guarantee 100% protection against fire.

- Not all types of warm floor can be used in the apartment.

- Electric floor can not be restored in case of breakage.

- Dismantling a floor covering in case of malfunctioning of the system is a time consuming, dirty and financially costly process.

- Electrical networks in the houses of the old buildings can not withstand the additional load.

- Power outages affect system operation.

Species

There are about a dozen varieties of warm floor, which can be combined into two large groups: water floor and electric.

Water

It is a heating system for heating indoor air through a flooring based on a system of pipes in which hot fluid (water or ethylene glycol) circulates.

It is customary to distinguish two types of water floor: a system with a heating cable inside the pipes (electrically conductive) and a system that is operated by an electric boiler.

- First type does not require connection to the heating boilerbecause the heating element is already installed inside the pipe along the entire length.Even the liquid inside the pipes is already there when buying a ready-made kit for assembly. They are enough to connect to a source of electricity 220V using a thermostat with an automatic temperature control system in the room.

- The second type does not have a heating element inside. is he works by gas boilerheating the coolant - liquid (usually water), temperature sensor and temperature controller. The water circulates through the pipes, cools on the way and returns to the boiler already cool to re-heat to the desired temperature.

The device of the heating system itself with the help of pipes and fluids with high temperatures also has several varieties:

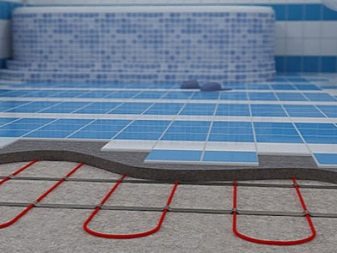

- Concrete. Heating elements are mounted inside the cement-sand monolithic screed. A reflective film is lined down, a thin sheet of fiberboard, chipboard, cork or other material that protects the floor covering from overheating is on top.

Installation of a concrete system is very time consuming, but reliable, therefore it is considered one of the most popular.

"Wet" work on laying cement-sand screed, given the time for complete drying of this screed, can take 20-30 days.

- Nastinaya.Due to the fact that all layers of the system are lined with ready-made materials, the work proceeds faster, cleaner and simpler, but such a system costs more. There are several types of flat-panel assembly technology:

- Floor polystyrene system. There is no concrete screed

- Flooring wooden system based on slats.

- Flooring wood system based on modules.

For apartment buildings, the state of which is assessed as good or excellent, you can choose any option. But for old buildings and houses with a poor operational condition, rack-mounted “designers” and embedded modular systems are more suitable.

Advantages of a water floor:

- Elements of the system can be installed under any type of flooring, whether it is tile, laminate or linoleum;

- The total cost of the whole structure is cheaper than the electrical system;

- Helps to save electricity costs up to 40%, which significantly reduces the amount in the receipt for payment for electricity;

- The autonomous control system is not affected in any way by interruptions in electricity;

- Water floor is more likely to replace centralized heating;

- Long service life.High-quality installation of the system ensures its uninterrupted operation for up to half a century, while the restriction on the electrical system is 20 years.

- Water floor successfully replaces all heaters, mobile convectors, fans and other systems of additional heating of the room in the cold season. Convectors dry the air, heat it unevenly, like centralized heating, and are not fire safe. And from an aesthetic point of view, they are not always relevant in the interior. Water floor is not visible to the eye, it does not create stuffiness and the greenhouse effect and is as safe as possible against fires in case of breakdown.

Do not rush to conclusions and mark for yourself a water-heated floor as the best option, because There are even more disadvantages to this type of heating system than advantages:

- Water floor heating is prohibited to use in an apartment building. Its installation requires expert assessment of the state of a dwelling house, compulsory coordination of the installation in all necessary instances and a separate heating circuit or boiler with a pump and a thermostat;

- Under the floor, with constant heating and lowering the temperature of the liquid in the pipes, condensation may form, and as a result, an unpleasant odor, fungus or mold;

- If the system breaks down, hot water may leak;

- The system is not recoverable;

- It is not recommended to install in rooms in which the ceiling height is below 3 meters. The pipe system occupies a fairly large space under the floor (15-20 cm) and eats the necessary extra centimeters in the room;

- Room space is desirable from 20 square meters. meters The fact is that it is very difficult to bend the pipes with a small step in order to warm up the floor as evenly as possible. This is made easier with an electric cable that is compliant for any manipulations in the floor heating system;

- Water heated floors more difficult to regulate. This is due to the fact that the water does not heat up and cool down in one second, it needs some time. Accordingly, the heating system is also not able to instantly heat cold pipes to become warm, and cool the hot liquid in them.

Electric

This is a floor heating system, which is based on the conversion of electrical energy into heat.

The electric floor appeared later than the water one, but it is developing more rapidly, and today there are three main varieties of this system: cable, heating mats, film floor.

Their advantages and disadvantages differ in some aspects. Electric floor heating system generally has the following advantages:

- Does not create convection currents, uniformly warming the air from the bottom up;

- In one room, you can install several independent systems and warm up areas as needed. The same autonomy works in different rooms, so the level of heat can be adjusted to the degree;

- A smart monitoring system allows you to set auto-start timers, prevents the system from overheating and ensures security;

- The system is under the topcoat on the floor and is not visible to the eye;

- It is combined with different types of materials for finishing;

- When the heat level is increased or decreased manually, the system quickly adjusts to the new parameters. The floor area warms up and cools very quickly.

Cons of electropole:

- Costly system and services of professionals in its installation. It is possible to do the installation yourself, but it is not recommended, since this is work with an electric current, it can be dangerous to life and health;

- The high level of electricity consumption, and as a result - the growing numbers in the payment receipt.Manufacturers are working to eliminate this drawback, but so far only the IR floor is relatively cheap to operate;

- A floor covering without special marking that allows laying on a warm floor may crack with time;

- The system is afraid of water. If it is flooded in an emergency, it will burn and will not be recoverable;

- With all precautions, electric flooring is not completely safe;

- Before installation, you must replace the old wiring.

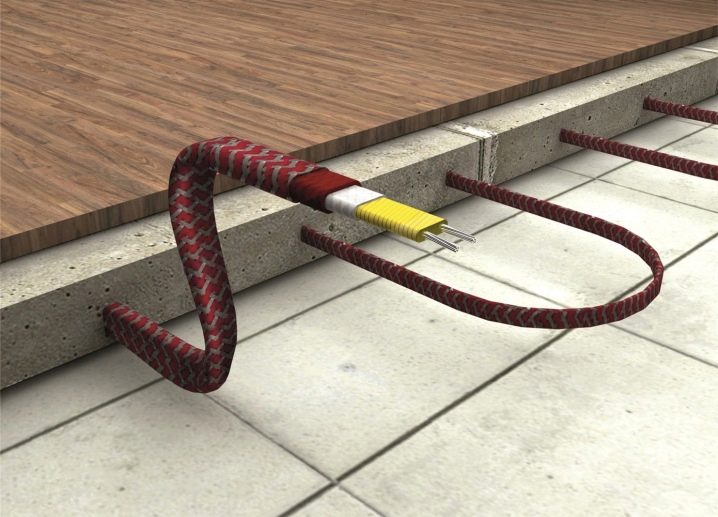

Cable

Cable electric floor is considered the most common, although not the best option. His device is very simple: a heating element (the cable itself), a thermostat, a sensor, a coupler. Separately, you must purchase a reflective film, which is placed under the system so that the heat goes up, not down, to the ceiling of the neighbors.

It is recommended to protect the system from above with a film so that during wet cleaning the water does not get into the system.

There are single-core (only heating element) and two-core (heating and heat element returning element) floor cables.The latter are more modern and practical, since their temperature varies with the ambient temperature and they do not overheat. They perform better in exploitation, but they are more expensive.

Cable thickness up to 3 mm is mounted directly into the glue, from 3 to 6 - is poured with cement (a screed is made).

The advantages of this type of warm floor:

- The cable can be laid even in those places where there is furniture. Overheating does not threaten him;

- The flexibility of the cable allows you to lay it, bending in the right direction with any step - from 1 cm to 1 m.

- Heats the room quickly, like all electrical systems;

- Suitable for combination with different types of finishing;

- Even the simplest cable system has a smart temperature control system;

- High efficiency - up to 97% of the electric current is converted into thermal energy.

Disadvantages:

- High demands on the condition and quality of the subfloor. Its surface should be dry and even with a maximum deviation of 1 mm;

- Serious energy consumption - half of it goes on a thick tie;

- Material for finishing the floor must have a thermal conductivity;

- Alignment of the subfloor, cable thickness, screed thickness (about 3 cm), all substrates and protective flooring, plus the thickness of the finish coating “eat” not less than 5 centimeters from the total height of the room;

- Cable electric floor emits electromagnetic waves. The harm of such sex on the human body is not proven, but it is difficult to call useful electromagnetic radiation;

- Cannot replace central heating.

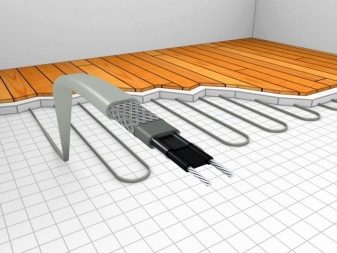

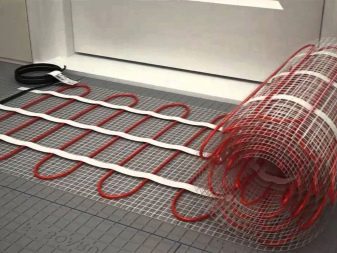

Heating mats

The basis for creating universal in the use of heating mats served as industrial heating plates to create local heating at agricultural enterprises.

Having undergone significant changes in their device, in the construction market appeared heating mats - heating mats for floor heating. They are used in the apartment, and in a country house, and on the street, because it is one of the most convenient and suitable for different atmospheric conditions, a type of heating system.

The basis of the mats is the heating cable, built into the mesh of durable fiber. Like cable floors, they are single-core (for non-residential premises, common areas, balconies, loggias and streets, for example, a porch so that there is no icing) and twin-core ones - with a low level of radiation of electromagnetic energy (for living rooms, bedrooms, for children) .

The width of the mat rarely exceeds 50-60 cm, the length can be any.The step distance at which the cable “zigzags” are formed is 5-7 cm.

It is important to take into account that single-core mats are arranged more primitively and are laid in such a way as to finish in the place from which they started, or you will have to pull an extra cold wire. With a strong one, this problem does not arise, you can finish putting it anywhere.

Two-conductor cables are able to cope with heating the entire premises without central heating, but this method will lead to significant financial costs. It is usually used as an additional source of heat.

Different rooms require different types of mats. For corridors and hallways, 120 watts per square meter is enough; bathrooms and kitchens need about 150–160 watts per square meter. m, and living rooms - in the power of 200-220 watts.

Teplomats have many advantages:

- Easy installation. They are fully prepared for laying on the subfloor, have all the necessary layers to reflect the thermal energy, protect the system and its safety;

- Easy to calculate the right amount of material;

- The absence of a thick concrete screed saves energy consumption by half;

- The low thickness of the mat does not require much raising the floor.Level changes will be minor - 1-2 centimeters;

- High speed;

- Efficiency - up to 98%;

- Intelligent control system, the presence of additional functions (heating for a certain time, maintaining the desired temperature, emergency shutdown).

Disadvantages of heating mats:

- High cost per meter of mat;

- Mats with a double core cable are more reliable, but cost more;

- If water gets on the system, it will burn out and will not be restored;

- Long time exposure before operation. After installation, it should take at least a month before the system can be started. All this time you will have to delay the finishing, as its dismantling in case of malfunctioning will be a lengthy and expensive exercise.

Film

Film, or infrared floor is the most perfect and progressive among other heating systems.

His work is based on the interaction of heating elements of organic origin (carbon, graphite) with electrical energy, which turns into heat and heats the floor directly, not the air around it.

The heating elements are reliably protected by a unique design,the total thickness of which does not exceed 5 millimeters.

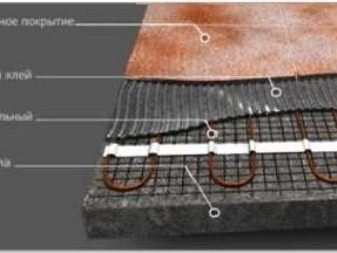

The design of the film floor includes the following elements:

- Dense polymer film, which is both a base and a stabilizing element. Over it a thin layer of reflective film of high-strength lavsan fibers is applied, so that the heat goes up to the floor. The layer is fireproof: the melting point of these materials is above 250 degrees Aim.

- Built-in heating element: carbon bands or fibers, and in the latest generation models - a solid carbon plate.

- Metal tires for the supply of current to the heating elements. The metal can be different: copper, silver, a mixture. Unlike cable, they have a flat shape, so the film floor is so thin (from 2 to 5 mm).

- Connecting element. Its role, as a rule, is performed by a special adhesive that is resistant to high temperatures and does not contain substances that produce harmful fumes when heated.

- The top layer of PVC film. It creates protection from external influences, the formation of condensate, accidental ingress of liquid to the heating system.

There are two types of infrared floors: film and rod.

The core floor is intended mainly for rooms in which the finishing is made on the basis of adhesives - tiles, tiles, and porcelain stoneware. Its thickness is more than a few millimeters; it is not covered with a film that can be eaten by construction glue.

The rod floor consists of a narrow mesh up to half a meter in length, on which are placed metal tubes with an organic heating element inside. Between themselves, they are connected by twin wires.

Tapes with tubes are placed on a heat-reflecting film on a frame base, fastened together, and covered with a protective film resistant to melting and the effects of adhesives.

Foil floor is a film of large width and small thickness - up to half a centimeter. Inside the sealed film is a heating plate and contacts for the supply of current. He in all respects wins from the rod and other types of electric floor due to its advantages:

- Mobility. The foil floor is not poured with cement and is not attached to the subfloor in any way. It can be disconnected from the power source, rolled into rolls and moved to a new place;

- The ability to change the size of the plates.The heating elements inside are divided into many small sections, and fragments of the desired size can be cut along special lines;

- The autonomy of sections from each other gives another advantage: if one section is damaged, the others continue to work, and the uniform distribution of heat remains the same;

- Efficiency - 98%. With a uniform distribution of heat, this allows you not to overlay the film in sheets entirely on the entire subfloor. Between them, you can make gaps of several tens of centimeters, which saves on material;

- It is simply mounted even without the help of professionals;

- Does not increase the height of the floor due to the lack of screeds, additional protection and its own small thickness up to 5 mm;

- The distance between the heating elements is less than 5 cm (the minimum possible cable spacing), which means that the heat is transferred to the flooring as evenly as possible;

- System power consumption is lower with greater efficiency;

- Replaces heaters and convectors;

- The maximum heating temperature that any floor covering will withstand is 33 degrees. This is enough to use an infrared film floor in some regions as the main source of heat in the room;

- Ability to mount on vertical surfaces.

We should also note the important difference between the film floor - it works on the principle of infrared radiation.

In nature, its source is the sun, so many tend to consider the infrared floor harmful to health, because when it is used, the rays directly affect the body. Indeed, in large quantities, short infrared waves lead to a painful state, but this is taken into account in the design of the film floor, so it gives radiation to the long wavelength. Remaining uniform and constant, it strengthens the immune system, triggers the mechanisms of regeneration of the body and has a positive effect on the emotional background.

But even such a system has drawbacks:

- The subfloor under the film system must be in perfect condition, flat and dry;

- The design of the film floor involves several contacts to supply electrical current. Ideally, they should work the same way, but some of them cope with the work worse or can not cope at all. If you make a wrong choice, you will have to reconnect the contacts again;

- 220 Volt - potentially dangerous voltage for the human body.It is necessary for the operation of the system, but even the presence of grounding and an automatic emergency system does not guarantee 100% safety in the event of an accident or breakdown;

- The basic package of the film floor necessarily includes thermal sensors and a mode control system, and the service life of these devices is usually less than that of the system by 10–15 years;

- For all its efficiency, the film floor is powered by electricity, respectively, its consumption increases. The more rooms are equipped with a warm floor, the more spending;

- The temperature of the floor is dependent on the interruption of electricity;

- Damaged areas cannot be repaired;

- Furniture should not be placed on the floor with film heating - it will burn out. Only models with legs that rise 5 or more centimeters above the floor are suitable;

- Soft flooring types of carpet and linoleum must be further isolated from the heating system with a protective substrate;

- If the flooring is too thick, the system will not warm up the floor surface.

Installation

The process of installing a heated floor depends on its type. The most time consuming process is the installation of a water or hydraulic floor. It is carried out in stages:

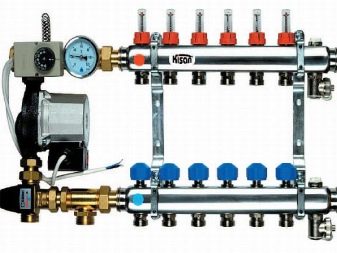

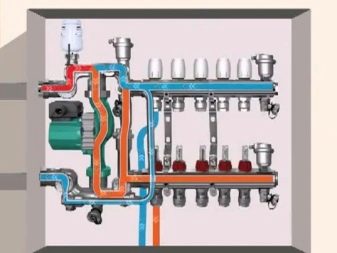

- The choice of materials and tools.The design of the system itself includes a boiler, a tank, hot and cold water outlets, an electric pump, a pressure gauge and manifold, and pipes under the floor. Accordingly, for the assembly, including the preparation of the subfloor, you will need a reinforcement system, a thermal insulation substrate, a boiler for heating water with a pump (not always included in one set, but both are necessary), ball valves for installation at the inlet of the boiler, adjustable pipes , collector-regulator for setting the system, pipes on the floor of polypropylene, fittings for laying the route boiler-pipe-collector, clips and fixing strips on the adhesive base.

An important part of the design is a three-way valve that regulates the temperature of the water entering the pipes. For example, if it is higher than acceptable, a valve with cold water opens in the mixing unit, liquids mix, the temperature level drops to the norm.

Pipes laid out on the floor should have a diameter from 15 millimeters to 30, heat resistance - 90-100 degrees, pressure - 9-12 Bars.

A collector is a splitter that is required to connect two or more heat loops to the boiler and to take back cooled water.It also contains all the valves, traffic controllers, air vent, emergency service systems and a controller.

Directly in work necessary tools are needed: tape measure, drawing accessories, tools for cutting plastic and metal (bolt cutters, cutter, grinder, etc.), pliers, screwdriver set, fixture, mounting tape, screwdriver, adjustable wrench and wrenches, level. For the screed, you need concrete or cement mortar (you can buy ready-made), a concrete mixer, spatulas and spatulas.

- Calculation of pipes, the creation of schemes for their distribution over the floor surface. Despite the seeming simplicity, this stage is much more difficult than the installation itself, since any errors can lead to the fact that the system will not work. For accurate calculations, it is recommended to use special computer programs, and even better - the services of professionals.

For the calculations (the required length of the pipe, the installation step, the route of laying the pipes) it is necessary to provide them with the following information:

- Space in square meters;

- The type of materials used in the construction of floors, walls and insulation;

- Type of insulation for floor heating systems;

- Planned type of finishing floor;

- The planned placement of furniture. In the places of its installation it is undesirable to lay a cable;

- Pipe diameter;

- Boiler power.

When making calculations, specialists will take into account such important points as the fact that the pipe installation step should be less (not 30, but 10-15 cm) along the outer walls of the room and windows, and the farther from the boiler, the lower the water temperature in them.

- Preparation of the subfloor. The water floor needs the most even and warmed (so as not to freeze the water in the pipes) surface of the subfloor.

To prepare it, it is necessary to dismantle the old screed and the system, if it was installed. Then level the work surface in the presence of height differences of 1 cm or more. Behind this, a layer of waterproofing material is laid out, and on top of it is a heat-reflecting substrate. It is necessary so that the heat goes to the floor, and does not go to the ground. Foil, expanded polystyrene or expanded clay plates are suitable for this purpose.

The last stage of the floor preparation - laying reinforcement screed. Without it, it will not work out a quality and even screed, and it is precisely to it that the pipe clips are attached.

- Installation of the collector box and collector.The complexity of the device depends on the requirements for the heating system. The maximum automated system with all valves and protection in emergency situations is many times higher than the cost of the simplest collector. The device is placed in the so-called collector box.

Installation begins with the installation of the box. The assembly is carried out according to standard instructions with the use of tools and does not cause difficulties even for a non-professional master.

- Installation of the boiler. The main requirement for the boiler is the compliance of the system capacity and a margin of 15-20%. The boiler is also mounted according to the standard instructions simultaneously with the pump, the capacity of which corresponds to the load on the pipes.

- Pipe installation. To maintain the uniformity of the step, use plastic dowels. They are attached to the floor, and then the pipes themselves are inserted into the nests in them and are attached to the reinforcing mesh with clips. Do not overtighten the pipe too much, the loop should remain a little loose. At the ends of the pipes is installed insulation from polyethylene foam, then they are fed to the collector. In the joints, a fitting or euroconus system is used.

- System checkIt is held for 24 hours in the presence of water in the pipes and a pressure of 6-7 bar. In the absence of leaks, defects and expansions in the pipes, you can proceed to the last stage - pouring the screed.

- Fill screed. This is a separate complex process consisting of several stages and requiring the participation of professionals. It is important to consider that the tile under the tile must be at least 30 mm and not more than 50, and for other materials for finishing (laminate, linoleum) - up to 30 mm.

Installation of an electrical floor is easier and takes less time, but it carries a health risk if the work is not performed by a professional.

Not all types of electric floor heating can be mounted independently. Cable flooring is a system that only a professional should install. But during installation work, the presence of the customer is important to ensure compliance with all rules and regulations. It is important to pay attention to the following points:

- You can purchase a cable only after careful calculations. You cannot trim it, so two problems may arise: it will not be enough and one of the sections will remain unheated, or it will be too much, then you will have to dismantle the installation and start over;

- The recommended laying step per square meter is specified in the cable passport.With the increase may appear the effect of "thermal zebra", and with a decrease there is a risk that the system will burn from overheating;

- Do not lay the cable closer than 50 mm to the wall;

- Laying is not made under massive furniture that does not stand on high legs and has no space for ventilation: headsets, walls, wardrobes, sofas.

- Installation workers must be familiarized with official documents indicating the location of communications (centralized heating). Next to him, too, do not lay the cable;

- The draft surface of the floor must be dry and even and laid with a heat-reflecting layer;

- It is important to secure the cable to the reinforcing mesh. A screed prior to solidification is a liquid solution in which a loose cable can “float”;

- The cable does not bend at a right angle;

- Impose it in several layers is prohibited;

- If indoors the finishing covering is planned to be combined from different materials (for example, tile and laminate), it is required to lay two different heating systems under them;

- Lighthouses for screed filling should be installed as accurately as possible, without plaster on the cable (it has poor heat conductivity);

- A thermal sensor is a component of a thermostat, not a cable, so it should in no way touch the cable. It measures the temperature in the air, not in the system;

- Prior to the connection of the screed, you need to check the performance of the system and the resistance between the cable cores. It should coincide with the figures in the passport system;

- It is necessary to transfer the laid floor scheme to the passport, marking on it all couplings, couplers, location of the tube and sensor;

- In rooms with high humidity, an RCD is required;

- Ideal screed - 30-50 mm without cavities inside. In places where there are wooden floors, and this thickness of the screed will not work, use foam or expanded polystyrene;

- Complete drying of the screed - 4 weeks or a month. It is forbidden to turn on the system before the expiration of this period.

Teplomatov

The modification of the cable floor to the finished mats has greatly simplified the installation process. Such a system can be mounted by hand, without having much experience in installation work.

Installation is carried out step by step:

- Calculation of the required length of the mats and their number taking into account the furniture in the room. It is also important to take into account the location of other sources of heat in the room and keep the distance between them and the mat at least 50 mm.At the same stage a drawing of the scheme is drawn up, according to which the mats will be laid. The drawing should reflect the location of the radiators, sensor, couplings and mats connecting sockets to the power grid.

- The choice of location for the installation of the thermostat and the system control panel. They are mounted in the wall to a depth of several centimeters. When the optimal location is chosen, a wall shall be cut in the wall and floor to connect the connecting wire with a thermostat.

- Preparation of the subfloor. Like any system, it is laid on a dry, maximally smooth and prostrate surface of heat-reflecting material.

- Thermomats are laid. They can be cut along special lines to go around the places where furniture will be installed that does not rise above the floor.

- A thermostat and a corrugated tube with a thermal sensor are placed inside the gate. The end of the tube is closed with a cap that will prevent cement mortar from entering the sensor.

- After the system is connected, a check is performed for the operability and compliance of the data with the data in the system passport.

- The last layer before finishing is a layer of tile adhesive (up to 5 mm) or leveling primer (10-15 mm).

- The system can be turned on again after the upper layer is completely dry in 7-8 days.

Film

Of all existing to date systems, warm floor, this is the most simple to install. To do it yourself, you must follow the sequence of steps:

- Selection of a suitable for the technical characteristics of a set of film (infrared) floor.

- Determination of the area on which the film floor will be laid and the layout of the sheets. It is desirable to put it on the circuit in the passport of the heating system, reflecting the junction of the film with the cold wire, the placement of the couplings and sensors.

There are two types of use of the film floor - comfortable and basic. In the first case, from 40 to 60% of the useful area of the room is closed, and in the second - from 70 to 90%. The same rule holds true when mounted on a wall.

- Worktop preparation. Foil floor does not tolerate flaws and dampness. If we are talking about installing in a room with high humidity, it is necessary to give preference to an infrared rod floor. Its installation hardly differs from film installation.

The subfloor must be leveled with a cement or primer compound if there are differences more than 5-10 mm in height.Then, after complete drying of the solution (about a week), heat-reflecting material is laid. As a rule, it is rolled and has a width of up to 1 meter, so the sheets are interconnected with tape (construction or painting).

It is important to take into account that for a uniform distribution of heat the reflecting film is laid over the entire surface of the floor, even if in some areas there will not be a heating element.

- Laying film. Between the fragments are connected by clips. The places for cutting and fixing the clamps are marked on the film and in the passport.

- Installation of thermostat. By analogy with the device for thermal mats, next to the sockets.

- Installation of wires for connecting the floor to the mains. It is important to correctly identify the place for stripping and work in rubber gloves. Electricity must be turned off.

Wires are located down along the wall or baseboard. For closed mounting, you need to pierce the strobe, and then seal it; for open, a special decorative box is used.

- The connection of the film with the wire. To do this, carefully remove the insulation from the end of the wire and pliers press it to the contact.

- Connection of wires with thermostat.

- Connecting the sensor to the controller.

- Connect the regulator to the network. This is a responsible and dangerous moment, which is recommended to be carried out either by a professional installer or after careful study of safety precautions in strict compliance with it.

- Test the performance of the system. If it works properly, you can mount the flooring.

Principle of operation

Warm floors are different, but all its varieties are one thing in common - they emit heat and transfer it directly to the floor covering, and not to the air around it, due to which there is a uniform heating of the room without dry air. However, each species has its own characteristics. Conventionally, they can be divided into three groups: water, electromagnetic and infrared floor.

The water floor system is powered by electrical energy, but it does not directly affect the floor surface. Electricity is necessary for the operation of the heating boiler and all systems that regulate the temperature of the water and supply it to the pipes, be it a mixing tank or a controller. Hot water passes through pipes located in the screed, heats the screed, and that, in turn, transfers thermal energy to the flooring.The higher the heat conductivity of the finishing material, the warmer the floor surface.

The temperature is regulated by adding and decreasing the degree of heating of water in the boiler. The recommended temperature is 28-30 ° C. It is important to note that passing all the way through the pipes, the water gradually cools.

Electromagnetic radiation systems include an electric cable floor. The principle of its work is based on the transformation of electrical energy into heat. This occurs inside the cable, which, with a small thickness, has a very complex structure: several types of wires for different purposes (conductive, drainage, heating), identification colored fibers, aluminum foil shielding and a fluoropolymer body.

Together, they transfer floor surfaces to a heat of 30 degrees Celsius.

Infrared heaters are arranged differently, and electrical energy is converted into infrared radiation, which tends to heat nearby surfaces.

The essence of the process of converting one type of energy into another is as follows: a current passes through metal tires (plates made of copper, silver, aluminum or an alloy of these metals) inside a fire-resistant and moisture-resistant polymer film.Passing through heating elements made of organic materials, it is converted into infrared radiation and heats the floor surface as the sun's rays heat the surface of the Earth - with the help of wave radiation. This ensures quick and harmless floor heating. Also, infrared rays have disinfectant properties and destroy odors and bacteria.

Thermoregulation

Any floor heating system has its maximum thermal threshold. Usually it is in the range of 30-35 degrees. But the maximum temperature is required extremely rarely, only in very cold weather, when the flooring works as an additional radiator in the house. Often it takes 24-25 degrees or less.

The method of controlling heat transfer depends on the type of floor and the complexity of the equipment. Based on the design features of the system There are several ways to change the temperature regimes:

- The use of low-temperature sources of thermal energy;

- Installation of various units and mixers;

- Support for a given mode;

- Sensors and additional equipment.

In practice, these are four simple and understandable ways. heat control:

- Manual. It uses a thermal head, which is installed on the collector. It works as a toggle switch that switches the temperature in increments from lower to higher, and vice versa. To change the level of heat, simply move the pointer to the division forward or back in a circle.

- Automatic. This is a more complex control panel that controls the system using buttons. On the panel there is a display where the designation of heat in degrees is indicated. It is not as accurate as possible, but it is not difficult to set a comfortable temperature.

- Individual. This is a system for setting a comfortable microclimate in a single room.

- Group. This is a single system that combines all the rooms equipped with a warm floor. Its main disadvantage is the inability to regulate the level of heat in a separate zone. And plus - you can adjust the desired level and the system itself will choose the working rhythm to keep it stable.

Sometimes they distinguish the fifth method - the combined one. But in its essence it is only a competent combination of individual and group control.

Systems managementoperating from electric current is also variable, but the power or temperature control of the floor is always used. They are of three types:

- Mechanical or electromechanical. The easiest way to explain the principle of its work is to draw an analogy with the regime regulator on the iron. To change the temperature of the floor, you just need to turn the dial with divisions. Its main advantages are simplicity, reliability and low cost. The main disadvantage is the inability to adjust the temperature of the floor surface to the nearest degree.

- Electronic or digital. It can be compared to setting the time on an electronic clock by simply pressing buttons. And the result will be visible on the display. This method gives visibility and the ability to set the desired temperature in degrees without error.

- Programmable. This is the most complex and perfect system. It is easy to operate (buttons or remote control), has a display on which all functions and readings are displayed, and allows you to adjust a constant temperature level or start the system and turn it off at certain hours. For example, the floor remains cool at night, and by the time the owners wake up, the system turns on and warms it up. The disadvantage of such a system is the high cost.

Which is better?

When buying a warm floor, one of the most important questions is which floor is better to choose? There is no definite answer. It is necessary to take into account many aspects at once:

- Technical characteristics of the system (energy consumption, speed and maximum heating temperature, manufacturer, floor surface temperature, service life, what type of control is used, which thermostat is equipped with the system, can it withstand damp and cold);

- Type of room (private house, apartment, non-residential, rooms of various functional inside the dwelling)

- Dimensions of the room;

- Operational condition of the premises;

- Installation technology and timing;

- Type of finishing floor.

Together, these factors affect the cost of the system and its installation, safety of use, quality and service life.

Universal and suitable for all types of premises is an infrared floor. For laying under tile, under tile adhesive, for rooms with high humidity it is recommended to use a rod infrared floor, and for other types of finishing in dry rooms - film.

This type of floor is as safe as possible for health and is equipped with automatic emergency systems, it is simply mounted and serves for a long time.It can be laid both indoors and outdoors or in farm buildings. Installation is simple and straightforward.

The price per meter of such a floor can hardly be called cheap, and the energy consumption for equipping the whole house and large premises is quite high.

Which heating is more reliable?

The best and reliable are not identical concepts when it comes to choosing a heating system for the floor, which will serve for a long time and without interruptions in work.

The best option is a water floor, if the house has gas. There are several reasons for this:

- The service life of a water floor and related systems is longer than that of an electric one - up to 50 years.

- There are systems that run on electricity, but the water is not in contact with it directly under the floor covering, so only an leakage is possible in the event of an accident.

- Water floor can not be installed in a multi-storey building above the ground floor - this is both a plus and a minus, since neighbors will not be affected during a leak. You do not have to pay damages on top of the financial costs of dismantling the system.

- The risk of breakage is minimal.

- Gas, as the basis for the operation of the heating boiler, is much cheaper than electricity.

- The gas system is independent of power outages.

- It is more profitable to install in large areas.

The disadvantage of this system is that it is not universal. It can not be used in apartment buildings, it is impossible to install in rooms with an area of less than 20 square meters and it is difficult to regulate with an accuracy of a degree. In addition, such a system warms up more slowly due to the fact that the thickness of the screed is not less than 30 mm.

For different rooms

From an attempt to identify the best and most reliable system, it is clear that this status is largely determined by the type of room.

For country houses and private cottages, water heated floor is more suitable. In apartment buildings, heating makers and infrared floors are more relevant. Inside the dwelling there are also different zones, the microclimate of which is more or less suitable for different systems.

Experts recommend using different systems for different types of premises, and sometimes combine two in one as follows:

- Bathroom, toilet, toilet, sauna. To maintain cleanliness and long service life of the coating in rooms with high humidity and low temperature (without add.heating) wear-resistant materials are used that are not afraid of contact with water and household chemicals. These are various types of ceramic tiles and artificial stone. Such a coating rests on glue or cement formulations, so a warm floor must be well protected and resistant to alkaline components. The best option is a rod floor.

- Kitchen and dining area. Resistant to mechanical damage and frequent wet cleaning are also popular here. The finishing covering which does not absorb smells is welcomed. Often, the cooking zone is finished with tiles, while in the dining area laminate is used. This room requires an infrared floor that destroys bacteria and odors. Under the tile - rod, under the laminate - film.

If this is a kitchen in a country house, then water floor will do.

Sometimes linoleum is used in the kitchen. In this case, you can give preference to a rod heat-insulated floor with the obligatory use of a solid separating layer up to 15 mm in thickness between it and linoleum.

You can use cable and water system with a coupler, but at the same time heat losses will be more.

- Living spaces. This category includes bedrooms, children's rooms, offices, living rooms. Often in residential areas give preference to a pleasant to the touch and beautiful-looking finish. It can be a laminate, parquet, board or soft covering - carpet (a substrate is necessary for it).

Rooms that are visited infrequently, it is enough to equip with a cable or rod floor in 150-180 watts. And for example, children’s, where the child spends all the time, and part of it is on the floor, it’s better to provide with a 200-220 W film IR floor.

Rarely, but still found in living rooms bulk floor. This is an expensive pleasure, and the thicker the layer is, the higher the cost, so a 4-mm-thick rod floor is best in this case.

- Cold rooms. If we are talking about balconies and loggias, the best choice - cable or infrared floor. For a private house where you need to warm the veranda or the passage through the room - water.

Manufacturers and reviews

Equally important to the quality and service life has a warm floor belonging to a particular manufacturer. Based on the reviews of the owners, taking into account the advantages and disadvantages, the top ten includes:

- Caleo. This Korean brand is a kind of flagship in the production of warm floor and tops every second rating in the Russian market. The secret of success is that Korea is the birthplace of the best floor heating for apartments - infrared. Numerous reviews confirm the excellent quality of the goods.

Among the positive moments, it is noted that it is possible to place a film infrared floor under soft coverings (carpet, linoleum) without an intermediate substrate.

- Rehau. This brand has earned recognition for its consistently high German quality, simple and clear control of the system and the most even distribution of heat over the floor surface.

- Energy. English supplier products are often mentioned in positive reviews as a system of excellent quality at an affordable price. The production uses safe materials, advanced technologies and components from proven suppliers.

- Spyheat. The domestic manufacturer is also in the list of suppliers who have received positive reviews. Spyheat systems are electric underfloor heating, fully completed and ready for assembly immediately after being released from the factory.

This fact is very important for those who want to reduce costs, time and effort for the purchase and installation.

- Ensto. The country of origin of this product is Finland. Severe frosts, as is known, a characteristic feature of the northern climate, therefore, all types of warm floor produced by this brand, 100% meet the expectations of consumers. Particularly loved in Russia is the line called “FinMat”, which was developed taking into account the specific features of the climate in our country.

- Electrolux. Unanimously named a quality and acceptable product.

- Warmstad. According to the owners - a synonym for "cheap and practical." Consumes less energy than others.

- Aura. Another sample of the German favorite of the German product, quality and reliable. A distinctive feature of the company is that when purchasing warm floors, you can not worry about the safety of the flooring, since for each type of cladding material the company has its own version of a warm floor.

- Heat plus. Safe heating based on organic materials is the specialty of this Korean brand. And in Russia it was highly appreciated.

- "National comfort", "Snail". Domestic manufacturers producing goods of European quality with a focus on the climatic conditions of our country.

Successful examples and options

Heated floor - a useful device for the home. It is convenient to use it for heating the living room, bedroom, kitchen, cold bathroom. But in addition to the standard application, it also allows to improve the climatic conditions in places such as a balcony and a veranda. In this case, in very cold rooms, some types of underfloor heating can be turned into heated walls. This system is very relevant for warming a balcony and creating a recreation area, a botanical garden or a dressing room there.

Recommendations for choosing a warm floor, you can learn from the video below.