How to make a ceiling of drywall with your own hands?

The choice of ceiling design is one of the most difficult, yet entertaining puzzles when repairing an apartment.

This article will help you not to get lost in the variety of variations on the theme of style, proper lighting and design design, so that upon completion of the repair work, the ceiling becomes the final eloquent chord in your new interior.

The building materials market is a gigantic variety of means to decorate floors, walls and ceilings. Much of the presented is suitable only for office space, while the other is advisable to use only in residential premises.

But there is a third option, universal - drywall, which is suitable for any type of premises.The ceiling seems to be the main visual element of any room, because when we find ourselves in a new place, the ceiling is the first thing we pay attention to.

Special features

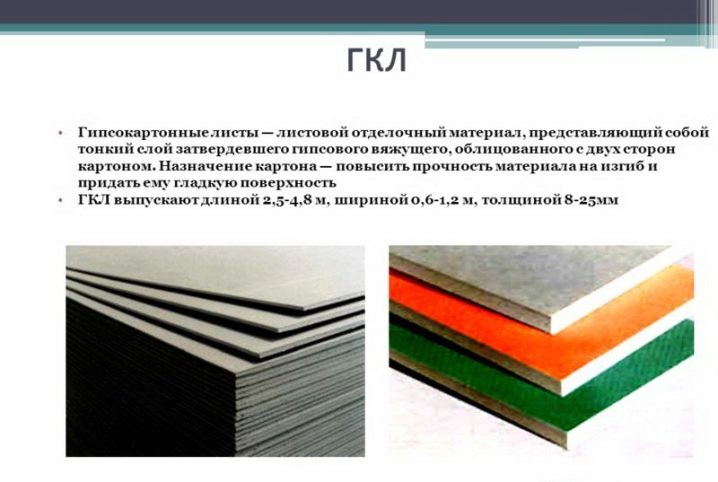

Gypsum board is a material used in construction for covering, installing partitions, and facing the ceiling, mainly in rooms with a dry and unsaturated environment. It is a sheet of two dense layers of construction paper and filler of thickened plaster with various additional fillers.

Drywall is a unique eco-friendly and clean finishing material.

This material is not amenable to burning and does not emit toxins, it maintains a favorable atmosphere in the room. The standard size of any drywall is 120 centimeters wide..

The gypsum plasterboard is fixed to the facing surface with the help of plaster mastic or on the batten using metal screws. Being an inexpensive, convenient and practical material, drywall for several years is one of the main elements in the construction work, which was preferred by many builders.

Formerly, the gypsum plasterboard was used exclusively for leveling the surface, but after some modifications and the emergence of a wide range of plasterboard sheets began to be used as structural elements. In particular, the material came to taste the designers for the creative possibilities that he gave them.

Drywall is not only able to level your ceiling, but also drastically change your interior.. The ceiling has an unusual shape with lighting, wall panels, a fireplace, an arch, a shelf, a partition, and much more - these are excellent solutions for identifying living areas that will make it more functional.

Advantages and disadvantages

Before you decide on a finishing material for a dwelling, it is necessary to find out all the advantages and disadvantages of drywall sheets. Possessing the knowledge and subtleties of this material, you can insure yourself in the future against frustration and all sorts of unpleasant situations in the process of repair. The use of drywall in the design of the ceiling has both positive and negative qualities. Let's analyze each of them.

Benefits:

- Easy installation. When installing a suspended plasterboard ceiling, there is no need to wait for the mortar to dry, given the dimensions of the living space and even the meager repair skills — no more than three days of finishing is done.

- Low weight material.

- Wide variety of shapes - With the help of drywall, you have the opportunity to embody multi-level designs of various shapes with unusual bends.

- High ductility - using water, drywall takes the shape you need.

- It has a high level of noise and heat insulation. Using this material, you will increase the insulation characteristics of the room.

- Camouflage communications. Easy and fast production of various designs in which you can hide wire, cable, pipe, duct and various types of communications.

- The surfaces of drywall constructions can be used for further painting., pasting any kind of wallpaper, revealing ceramics and tiles.

- Rich selection of material. The market makes it possible to choose the necessary drywall drywall of the required thickness with different operating properties.For example, moisture resistant material is used for cladding in a room with high humidity (kitchen, bathroom).

- Lighting system. Gypsum ceiling often used as a frame for any type of lighting.

With all the advantages of this material, it is worth being prepared for certain disadvantages:

- Reducing the height of the room. Suspended ceiling structures are taken away by the order of five centimeters in height due to the use of additional embossed profiles, respectively, are contraindicated in low rooms.

- The occurrence of cracks. If the drywall is installed incorrectly, cracks may appear at the joint in the future.

- To preserve the material in its original form, certain conditions are necessary, namely, it is prohibited to store drywall in rooms with high humidity and lack of heating.

- It is not advisable to use drywall for ceiling cladding in a room where there is a high probability of being flooded from above, as the gypsum board sheet swells under the influence of water, the mass becomes larger and the structures may collapse.

- When installing drywall shelves, it is not recommended to fix massive elements on them, since it is easy to damage the plaster "stuffing".

- At the end of the installation, it is extremely difficult to make extraordinary finishing works, to disguise the joints of gypsum sheets and the cracks that have arisen.

- Fragility. Gypsum plasterboard sheets may break during careless transportation, installation and operation, so you must be extremely careful and careful when repairing or building ceiling partitions. It is also recommended to refrain from using drywall where it is planned to install a heavy structure, for example, a massive chandelier. In this case, use for finishing a double layer of drywall. This will ensure a secure fit.

Kinds

After evaluating all the possible advantages and minor, but important to note the drawbacks, you must decide on a specific type of drywall that will meet your exact needs.

So, in the repair of residential premises there are several types of drywall. They have different properties. That they should focus.

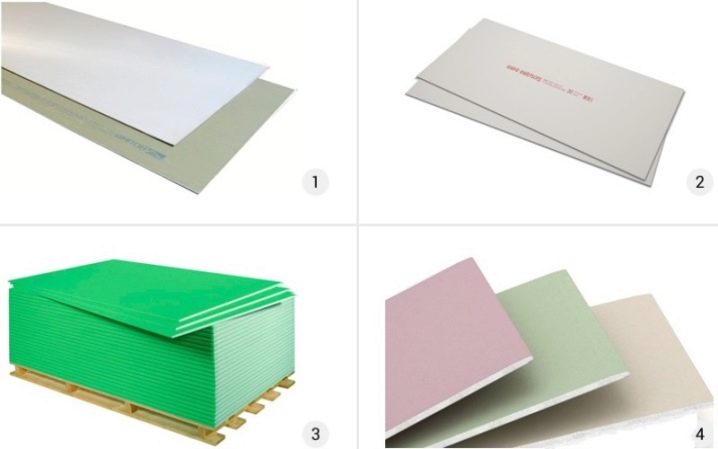

GCR - gypsum sheets, which are lined on both sides with a light and soft cardboard, fixed on the surface of the gypsum. The standard size of this sheet varies and ranges in length from 2,000 to 3,000 millimeters. The width usually remains the same - 1200 millimeters. Thickness - 12 or 9 millimeters. For residential premises it is recommended to resort to sheets with a thickness of not more than 9 millimetersto loosen the mass of ceiling structures.

It is widely used in the implementation of design and construction plans for the repair and installation of walls and partitions. At production the cardboard of gray shades is used.

GKLO - fireproof plasterboard sheets. This type of material, surprisingly, is not used in residential premises, but is widely distributed in industrial buildings, for finishing the duct and communication shaft.

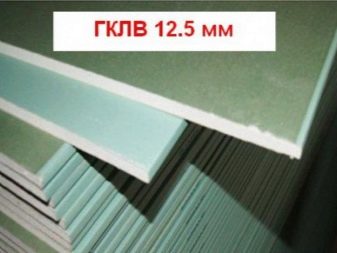

GKLV - moisture resistant plasterboard sheets. Used in rooms with high humidity, namely in the bathroom, kitchen, bathroom in the presence of exhaust ventilation and protection of the front surface of the waterproofing composition, waterproof paint, primer or finishing of ceramic tiles.At production the cardboard of green tones is used.

GKLVO - gypsum plasterboard sheets of a mixed look, possessing high resistance to fire and humidity, combine all the characteristics of the previously mentioned species.

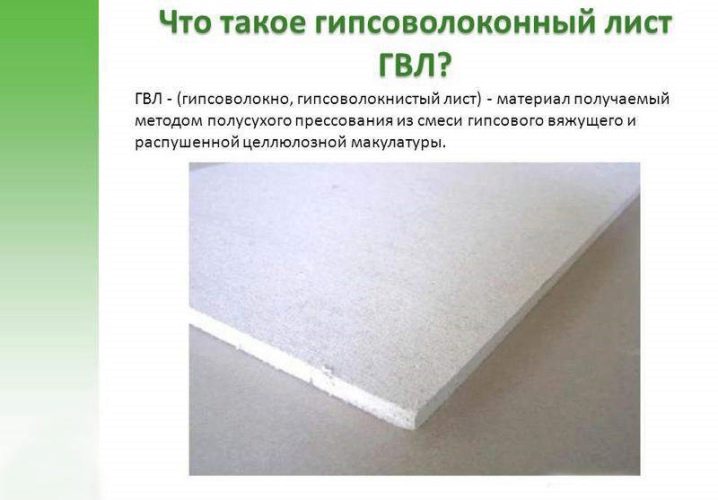

GVL - gypsum fiber sheets. At production are not fixed by a cardboard, as previous. Gypsum is strengthened with the help of special high-quality cellulose waste paper. This type of sheet has high strength and heat resistance to fire and flame. It corresponds to the standard size of an ordinary sheet with a thickness of more than 6 or 10 millimeters. GVLV - gypsum-fiber moisture-resistant sheets.

Arched drywall sheets have the smallest thickness of the previously presented species - less than six millimeters. Used to reproduce various kinds of designs of different radii of curves and curved lines.

Facade drywall sheets covered with a layer of fiberglass, have a standard thickness of 12 millimeters. At production the cardboard of yellow shades is used.

Plasterboard sheets with insulation - modification material, in which polystyrene foam blocks are fixed to standard sheets with adhesive base.Insulated layers reach 60 millimeters, which makes it possible to significantly increase the insulation parameter of the wall.

Vinyl Coated Plaster Sheets - Another modification of our time, which increases its versatility. The GKL package has been expanded and today you can purchase a profile with decorated vinyl coating, which will allow you to assemble walls with a ready-made color solution.

With the help of such GKL it is possible to make both single-level and multi-level ceilings.

Forms

The use of plasterboard to give a smooth surface to the walls and ceiling during the repair has long become widespread. Making complicated designs and decorating the ceiling has become available with standard gypsum board. Such ceilings create interesting lighting solutions and become real works of art.

There are many variants of the use of drywall forms, and for this it is not at all necessary to use the services of a builder or decorator. However, there are some conditions for the application of decorative forms on the ceiling cladding, which must be reviewed.

Rectangular ceiling plasterboard - This is a universal option, as it is suitable for all types of premises. He does an excellent job with his function - the correction of the shape of the room. For example, a rectangular ceiling is designed for narrow spaces, it will visually expand the walls.

Figured square ceiling made of plasterboard - This is a kind of rectangle, but it is found mainly in residential premises with relevant characteristics. With this type of room, a multi-level ceiling with a circle in the center of the structure is recommended.

Round shaped ceiling - the best option to highlight the center of the dwelling, for example, where it is supposed to be a table, sofa or a place with the largest crowd of people.

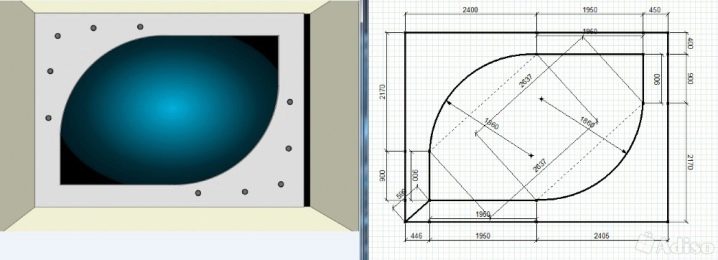

Oval and curved ceiling from drywall visually increases the room, this type of ceiling is used for unobtrusive zoning of space, regardless of its size and shape.

Ceiling abstract or geometric volumetric shape from drywall - it can be the shape of a flower or a geometric figure, it serves solely to give a decorative and extraordinary living space.

Project

To construct a complex multi-level gypsum ceiling it is necessary to resort to a specialized computer program, it will calculate the recommended amount of material.

In this article, we consider a single-level, without a complex decor ceiling structure. Creating single-level ceilings does not involve the development of a complex project.

It will not be difficult to calculate it at home, the only nuance in this project that cannot be ignored is how the lighting devices will be positioned so that during installation the lamps do not coincide with the location of the supporting metal profiles.

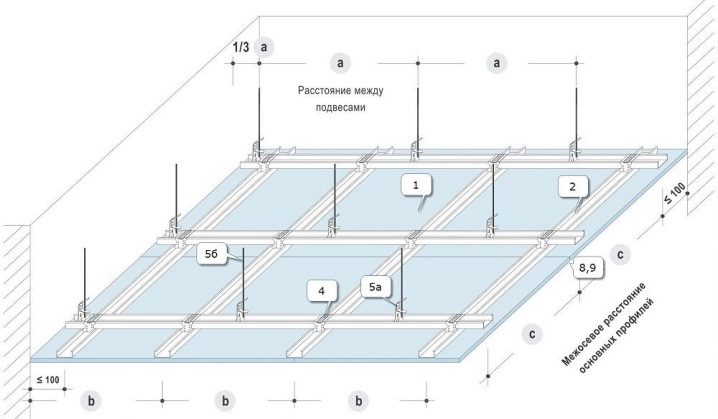

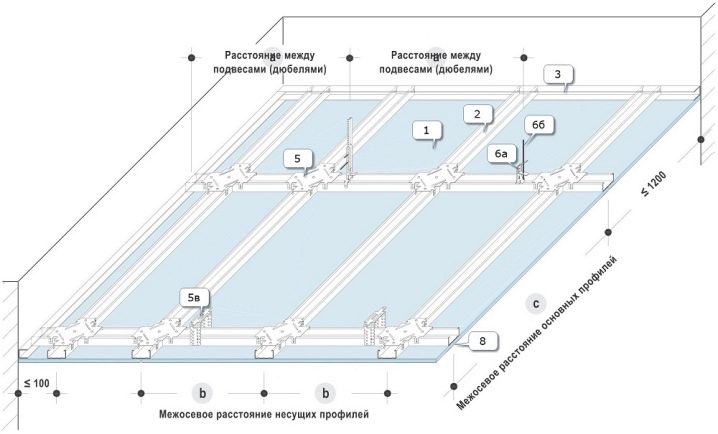

For clarity and approximate calculation schemes let us take as an example a room measuring 3 by 6 meters:

- The first one in the priority list is to calculate the perimeter of the necessary room, in this case P = 6 + 6 + 3 + 3 = 18 meters. This is the required number of guides of the ceiling profile. Be prudent and purchase a small supply in advance in case any difficulties arise during installation. Do not forget that often the walls in residential premises are not equal to each other, in this case, focus on the value that is greater.

- Then it is necessary to calculate the required volume for the supporting ceiling profiles. This device is very important. For example, take a gap of 50 centimeters in length - the distance over which the profiles will be fixed one after another. When a plasterboard sheet is fixed along the length of the room, the size of a standard sheet is 2500 mm, therefore, the borders fall on the supporting profile elements.

So, we substitute our parameters and do not forget that 6 m = 600 cm, therefore, 600: 50 = 12. Twelve pieces are the necessary amount of profile.

The second option is to place drywall sheets across the width of the room. In this case, the gap should be sixty centimeters long: 600: 60 = 10. Ten pieces is the recommended amount of profile.

- The next stage involves the calculation of the number of suspensions. The suspensions are fixed to the bearing profiles for a period of sixty centimeters long. For example, take a profile with a length of three meters. Accordingly, 300: 60 = 5. Five pieces - the required number of suspensions. We have twelve bearing ceiling profiles, therefore 12 * 5 = 60.

To the note: it is recommended to fix the first and last suspensions from the walls in the interval of 30 centimeters, and the remaining 60 centimeters from the adjacent ones.

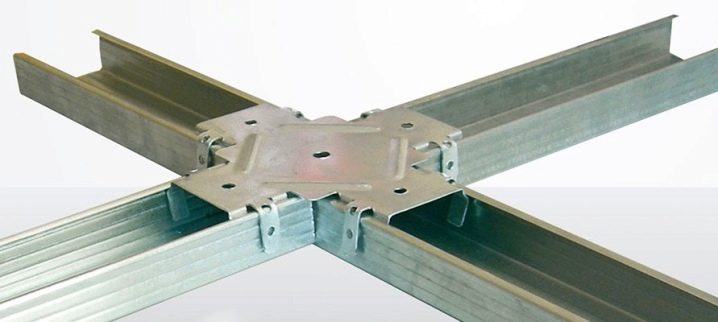

- At the last stage, the required volume of crabs is calculated - the cruciform elements for fixing the frame structure. In our case, the crabs are recommended to get 24 pieces, in other words, two times more than the profiles for the ceiling, calculated in the second stage.

Carefully write the drawings to make your work easier in the future.

Equipment and materials

An extremely important stage in the installation of the gypsum ceiling is, of course, the preparation of all the necessary materials and tools.

So, to work with drywall sheets are needed:

- guide profiles;

- ceiling profiles - do not give preference to cheaper material, since the manufacture uses a thinner material, which can lead to sagging;

- quite important device - U-shaped suspension;

- profile connectors;

- fasteners - dowels, anchors;

- sheets of plasterboard - the ceiling is usually installed from sheets whose thickness reaches 9 millimeters, with a larger size there is a risk of some difficulties (a stronger frame construction or alternative installation technology is required);

- metal and plasterboard screws;

- sealing tapes;

- materials for thermal and waterproofing;

- Decoration Materials;

- metal jigsaw and scissors, hammer;

- roulette, level - it is recommended to use two different levels (the first is up to a meter, the second is from two to 3 meters);

- construction knife;

- perforator, screwdriver;

- consumables.

Installation

Upon completion of the preparation of all the necessary tools and materials, after the development of the project, you can proceed to the most entertaining stage of all the work - the installation of drywall, as well as the finishing that follows.

You can hem the GKL yourself without resorting to the services of professionals, but it would be useful to ask someone to help you. The filing of this material should occur in several stages.

Frame and heat insulation

For a start, it is required to measure all the corners of a dwelling using a tape measure or level. The height is determined from all the shortest angle. We mark it 5 centimeters from the ceiling, provided that the installation of lighting fixtures is not planned in the future, 9 centimeters - with the planned installation.

Using a level similar marks are indicated in other corners.Then along the walls are indicated marks at the same level as the first mark. It is necessary to collect all the marks in one line when using a long ruler or a stretched lace - this is quite simple to do. Further on the walls are fixed guide profiles.

In a large room, it is advisable to pre-engage in strengthening the structure in the jointsto avoid the displacement of materials under their mass. Sheathe ceiling can be anything. For strengthening any dense materials will fit - plastic, plywood, which must be fixed on top of each joint and attached to the wall with dowels. After produce fixing the corner joints of the profiles.

Standard sheet of drywall - 120 to 250 centimeters, and therefore it is recommended to fasten the ceiling profile 40 centimeters apart, as the sheets will be fixed at the borders and in the middle. Next, the ceiling is marked by lines parallel to each other at a distance of 40 centimeters.

In places of transverse joint, you need to fasten a jumper of the same material as the profile. Then set the crab - a cruciform element for hardening the frame structure. Next, determine the location of the suspension. The main suspension is set at 20 - 25 from the wall, the following - at a distance of 50 centimeters.

Anchor is used to fix the suspension, the usual dowel in this case is not suitable, as there is no thread and there is a possibility that the structure may not withstand. Ceiling profiles must be attached strictly to the suspensions.. Start work from the corner of the room. And on this frame construction for the plasterboard ceiling is ready.

Special attention should be paid to the installation of thermal insulation. This is a simple and straightforward process that will require a little patience. The ceiling is insulated in the same way as the walls. After installing the frame structure empty areas that were formed in the middle of the frame and the existing floor slab are filled with mineral insulants, the base of which is fiberglass. Then you can do the laying of electrical communication.

There is one important nuance - Built-in lighting can cause overheating, and it does not matter what kind of lamps you have given your preference - energy-saving, diode or incandescent lamps. Powerful overheating provokes a number of unpleasant consequences.Wires located nearby may melt, after which at best there will be a short circuit, at worst a fire will occur.

If you remove a certain amount of insulation, it will solve the problem of overheating, but at the same time the thermal insulation function will be greatly reduced. In this case, it is recommended to abandon the installation of the built-in lighting system and opt for a chandelier or wall lamp.

The initial preparation of drywall pay special attention. He needs to rest for some time at room temperature.. Storage of drywall should occur exclusively in a horizontal position. At the initial stage, the chamfer is removed from the drywall. In other words, parts of the edges are cut at a 45 degree angle. This procedure is necessary to ensure the reliability of further finishing works. Today, many manufacturers produce sheets with finished edges.

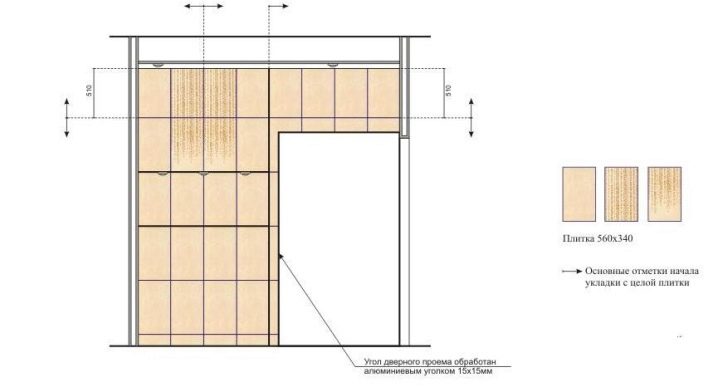

Installation of plasterboard sheets start from the corners.. They are fixed with screws at a distance of 15 centimeters. It is customary to place the screws on adjacent sheets in a checkerboard pattern. Sheets are attached slightly apart.. This means that the sheets do not fit on one line - this will allow drywall to gain a foothold more reliably. Installation of drywall finished, the final stage - finishing.

Finishing work

After the end of the main work on the installation of drywall construction, many are wondering what kind of finishing work will follow. There are a lot of variations on this topic - go painting, pokleit wallpaper, use decorative plaster or elements of polyurethane for decoration. The question is really difficult.

To begin with, the resulting plane must be made uniform - this will help to hide all sorts of seams, seams and joints of sheets. In addition, if there is a question about painting or finishing with thin decorative plaster, you need to level the ceiling in any case.

Water-based and water-dispersion paints are the most popular materials for ceiling finishing works.

Water emulsion is a paint consisting of small drops of oil, which are dissolved in water. Water dispersion paint is a combination of small particles of different polymers, it is resistant to washing and does not have a strong odor. Both are well suited for painting plasterboard surfaces., besides, they have one feature - it is possible to choose a matte base. This is true for the case when there are small errors on the ceiling that remain after the putty. It will perfectly mask them.

Paint on the basis of gloss, on the contrary, expose all the roughness and imperfections parade. Its use is appropriate only when the quality of the coating is ideal, for example, it is pre-pasted with wallpaper. On ceilings, the use of oil-based paint is not recommended.

Wallpapering suggests two options for subsequent events - with or without painting. The choice of shade and color is what you need to be careful and attentive with. An overly dark shade creates an atmosphere of a low ceiling pressing on you, and a light shade visually increases the height of the living room. Both options require you to take into account the existing relief pattern on the wallpaper. It makes no sense to glue embossed wallpaper, so that they are lost under the impressive layers of paint.

It is worth mentioning this type of finishes, like liquid wallpaper. This is quite often used material for finishing work,which fits nicely on drywall. They are similar in composition to thick paint, to which decorative filler has been added.

The choice of plaster for the ceiling is yours, the only thing that is not recommended to use decorative plaster on a watery basis. Gypsum sheet does not tolerate moisture, from which it begins to swell, loses its shape and the whole structure is deformed. In rooms with high humidity, decorative acrylic-based plaster is used. It perfectly copes with the effects of moisture and at the same time retains its properties.

The size of the filler plaster is divided into several types:

- low-impact - a filler up to 1 millimeter;

- srednefurnaturnaya - a filler up to 1.5 millimeters;

- large - a filler from 3 to 5 millimeters;

- fine-textured - filler is less than 1 millimeter.

When choosing a plaster, keep in mind that thin fillers do not mask the uneven surface. Prefer more dense fillers.

Tile - another attractive option for finishing plasterboard ceiling. But here there is one condition - it is necessary to pre-treat the entire surface of the gypsum ceiling with a primer. Ignoring this stage, the tile will not last long and will fall off at any moment.

Ceiling products are rarely trimmed with ceramic tiles, In this case, a material such as polyurethane or polystyrene is used.. Such materials stick easier and faster.

There are a lot of options on the topic of decorating the surface of drywall with your own hands, the choice depends on the characteristics of the living space and plans for the design of the entire room. Our step-by-step instruction will certainly help you to mount the drywall and trim the ceiling.

Do not neglect the steps and materials for preparing the surface for future finishing, for example, leveling the surface with putty.

Tips and tricks

Sooner or later, when working with drywall sheets, you will encounter a situation where the sheet will need to be cut to size. To do this, use a tape measure, ruler and a sharp construction knife, clerical is also suitable. Having made the markup, with the help of a knife, slowly cut the cardboard layer, trying to hook the plaster filler.Then put the sheet on the table border and with a sharp movement break the plaster filler to the bottom cardboard layer.

Preparatory work with plasterboard is not limited only to cutting it to the required size. If you want to get a flat surface, the joints and seams need to be masked after installation on a metal frame structure. The technology of chamfering at the edges of the gypsum board is used for this. The dimensions of the chamfers are directly dependent on the chosen method, which will be putty plasterboard sheets.

If you choose a method using reinforcing tape, then the chamfers are removed at a 45-degree angle. When using a putty with a self-adhesive serpianka, it is necessary to chamfer at a 25-degree angle, which is already two-thirds of the density of the sheet. For the production of this process you need to purchase a specialized planer on the edge.

Putty plasterboard sheets and sealing joints is inevitable if you need a flat surface without seams.

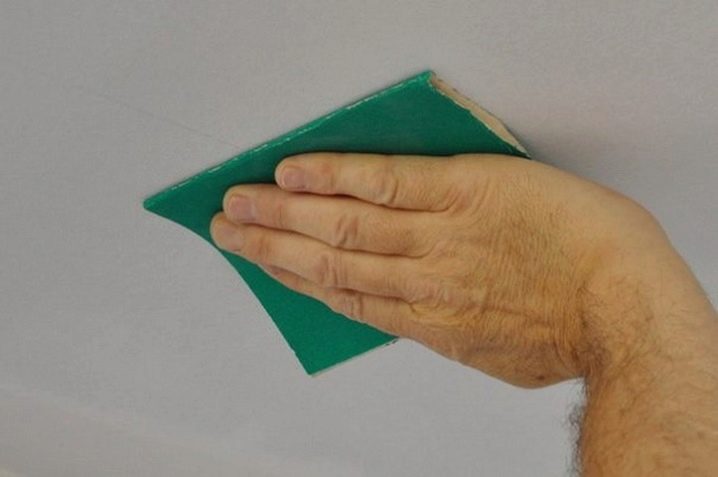

Grouting the joint and seam is done strictly after dust, chips, and other tiny particles left after installation are removed.. Then drywall is treated with a primer, which increases the adhesion of the sheets with putty. After the first layer, you must wait until it is completely dry, then a second layer is applied, and the surplus is removed with a spatula. After drying of the putty joint, it is actively polished using emery paper.. The same procedure is applied to places that are fixed with screws, as well as all corners.

As mentioned earlier, drywall sheets can take any sophisticated curvilinear shapes. Before you begin to give shape to drywall, you need to remember that dry sheets can be bent, provided that the radius does not exceed the established standards:

- sheet thickness 6 millimeters - radius not less than 1000 millimeters;

- sheet thickness 9 millimeters - The radius of 2000 millimeters;

- 12 millimeters thick - The radius of 2700 millimeters.

In the desire to save, many prefer the wooden frame created from the slats and beams. The function of fixing the gypsum plasterboard will be performed by such a framework, but how durable this construction is is another question.

It is no secret that wood has a low resistance to moisture and is even more susceptible to it than a gypsum plasterboard.As a result, you are waiting for the constant deformation of the frame made of wood, which leads to the emergence of new chips, cracks and uneven joints. In addition, wood is a natural material that many insects prefer. When working with drywall, the metal frame can give you a guarantee for a long and durable fixing of sheets and will relieve you of many difficulties in the future.

Beautiful examples in the interior

Gypsum ceiling is a good opportunity not only to give the ceiling a more elegant look, but also to play a significant role in the interior of the room, for example, to emphasize any object of the interior. In this case, the columns.

The sharp bends of the ceiling emphasize their massiveness and elegance. And the diagonal built-in light gives the space symmetry and harmony.

Complex constructions of drywall constructions immediately attract attention, give a new form to living space, changing it beyond recognition. The interior looks richer and more refined. Smooth flexible line, built-in lighting give an atmosphere of warmth and comfort.

The ceiling is recommended to make an exceptionally bright shade, this will further increase the space.

Properly chosen design of the gypsum ceiling radically changes the atmosphere of the whole dwelling: it will add height, volume, luxury and increase the space. The so-called soaring gypsum ceiling with lighting fixtures is one of the most popular options, suitable for both private houses and apartments.

The lighting installed along the border of the plasterboard construction gives the impression of a light and soft glow.. It is made not only for an esthetic look, but also for masking fastenings.

To learn how to make a plasterboard ceiling with your own hands, see the following video.