How many different types of floor screed dry?

Laying the floor - one of the most important stages of repair. To make the floor quality and durable, it must be laid on a well-dried screed. Therefore, it is necessary to sort out in detail the question of how many different types of floor screed dry.

How to understand that the screed is ready?

Screed is the base for the floor. Depending on the different types, it dries for about 27-28 days. After that, proceed to laying the flooring. Since the time required for drying does not always coincide with the specified manufacturer, you need to make sure that it is ready. This question is particularly relevant if the concrete screed is done in the apartment when the heating season has not yet begun.

If you lay the floor moisture-proof coating on top of a dry base, the remaining moisture will create conditions for the occurrence of fungus and mold.Concrete under its influence will begin to collapse, the insulation is broken. In the future, the finishing flooring will also suffer.

To determine the readiness of the screed, you can use two methods:

- The answer can give a visual inspection. The screed must be uniform, differing by a uniform color and structure over the entire surface. It should not be cracked.

- You can use a large plastic film and attach it to the screed using adhesive tape. A day later, the film must be removed and inspected. If there are no signs of fogging on it, you can continue to work on laying the flooring.

Drying of different types

Walking on the floor can be a couple of days after pouring. This does not mean that the base is ready for further installation. Dries the screed for quite some time. This process may take more or less time, depending on the time of year, the humidity indicators in the room.

Important factors are the number of layers and the thickness of the fill. Each next centimeter of coverage extends the drying time by at least 3 to 4 days. What matters is the look of the finishing flooring that you will use, as well as the look of the tie itself.Its composition often determines how long the filled solution hardens.

From sand concrete

Peskobeton - a popular material used in the repair. It is a mixture containing concrete, cement and sand. From it turns out especially strong and strong basis. When laying it must be carefully sealed, to subsequently avoid the appearance of air bubbles.

The cement-sand screed is rather heavy, it is the easiest to manufacture. This mixture can be prepared with your own hands. However, in order not to be mistaken with the proportions and quality of sand, it is better to purchase ready-made mixtures that are sold in hardware stores. From a fairly wide selection, the most popular and optimal will be the sand-concrete mixture M 300. It is in demand for its strength and durability of the coating.

1 cm sand concrete screed dries for about 7 days. The recommended layer is 3-4 centimeters. It is easy to calculate that it takes 28 days to dry completely.

Such a long period of time can be considered a disadvantage, but the M 300 has indisputable advantages:

- it almost does not shrink;

- she is not afraid of a temperature drop;

- It is fire resistant and moisture resistant.

To speed up the drying time of the base, manufacturers often add fillers to the mixture, which help speed up the drying.

10 cm

In many situations, a thick coat is required. For a 10-centimeter layer, a wet screed is often used. It is universal and suitable for laying on different types of overlap (even on the ground). Any finishing materials can be laid on it. It is easy to lay, the procedure can be done by hand, which significantly saves money spent on repairs. This screed aligns the level of the floor in different rooms, it is strong and durable.

However, the thick layer of the screed has a long drying period. Usually it is more than a week by 1 cm: for each additional centimeter above the thickness of 4 cm, it will take twice as long (for a 10 cm thick screed, it is necessary to wait at least 16 weeks of drying).

If you are going to lay ceramic tiles, the remaining moisture can be disregarded. If you want to lay parquet, it may take six months. For screeds with a thickness of 10 cm, there is only one way that does not require time for drying - a dry screed.It is based on a hollow wooden frame filled with expanded clay. On top of it, make a coating of plywood sheets or use chipboard.

Under the tile

The readiness of the tile under the tile depends on its type. More often the tile is laid on a cement basis. You can walk on the cement the next day. You can start laying tiles on such a basis on the next day, as the cement quickly loses moisture. While finishing work will be carried out, the screed will dry completely. It is important to observe the condition: the installation of furniture can be carried out not earlier than 10 days after lining. However, professionals do not advise to rush, explaining that it is necessary to give the cement to dry well.

If you are going to lay tile on a sand concrete screed, use the usual method of calculating the time for drying (1 cm = 1 week).

With a standard approach, a 4 cm tie is required. Therefore, it is necessary to wait 28 days. Making such a basis, it is important to wait for complete drying, otherwise the surface under the tile will not be even. It is not necessary to speed up the drying process with drafts; it is recommended to periodically wet the surface at high ambient temperatures.Failure to comply with these conditions will result in cracks in the screed.

5 cm

The 5cm thick screed can be made of different materials, which makes the drying time varies. For example, sand-cement or concrete will take 6 weeks. Recently, gypsum foundations for laying flooring have become popular. They are durable, do not crumble and are ideal for dry environments. Their setting occurs within a few hours.

Gypsum base for the floor is ready in a week if its thickness is 4 cm. The time is calculated as follows: for 1 cm of the layer it takes 42 hours to dry. For each next layer with a thickness of 1 cm you need to add 90 hours. Consequently, the 5 cm layer will dry for 13 days.

If the coupler is made semi-dry, the drying time is significantly reduced. You can attack it after 12 hours after installation.

Three or four days of drying is enough for the subsequent laying of linoleum or tile. If you need to put the floorboard, it will take a week.

Semi-dry

To carry out repairs in a shorter time, apply a semi-dry screed. Its drying time is 4 to 7 days.This is achieved by adding to the cement mortar special substances, called fillers. Cement mortar filled with expanded clay, fiberglass, basalt, polystyrene foam granules. They remarkably absorb water from the solution, reducing its amount almost by half.

The semi-dry screed has its advantages:

- It has less free water, which should evaporate, so the structure does not form voids and pores. The coupler turns out more dense and strong.

- Since there are few pores in it that contract during cement hardening, it practically does not shrink.

- You can walk on it in 10-12 hours.

- It does not create a high level of humidity, so you can begin some finishing work in the room.

Semi-dry screed spreads worse, especially in the corners. It is necessary to add plasticizers. Due to quick drying, too thin of its layer will not have time to adhere to the base, too thick will be heavy. When using a dry screed, special technologies should be used to obtain a high-quality coating.

Under the laminate

For laying laminate you need an almost perfectly smooth surface so that the panels do not creak and do not bend.

Therefore, use the following types of screed:

- dry or plywood;

- self-leveling compound or self-leveling floor;

- cement sand.

The name “dry” speaks for itself, other species must be completely dried, otherwise unpleasant consequences cannot be avoided. The drying time of the self-leveling floor depends on its composition.

Floor mixes can:

- be based on polyurethane, epoxy;

- contain cement, resin.

Drying time varies from 6 to 21 days. The cement-sand variety will dry for at least 4 weeks.

Draft

In some cases, before finishing the tie you need to make a rough. It does not have to be flat and smooth.

Its purpose is as follows:

- align ground level drops;

- interlock the floor slabs at the base of the floor;

- hide pipelines and other engineering communications.

It is often laid on the ground during the construction of the garage, cottages, verandas. Draft floor often made of concrete. This is a heavy material, it has a low vapor conductivity. Walking on it will be possible only 7 days after the end of the work. 7 days are given for drying for each 1 cm layer. With a thickness of more than 4 cm for each cm add 14 days.If the base has large drops, to calculate the drying time, take the thickness of the deepest place (from the bottom to the surface).

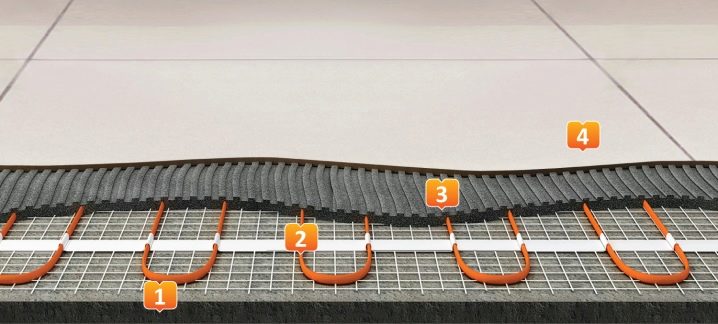

For warm floor

Screed for underfloor heating has its own characteristics:

- levels a surface for laying of a finishing covering;

- hides and fixes the heating elements;

- is a protective layer for the heating system;

- prevents mechanical damage to the heating system.

Such a screed itself plays the role of a heater, accumulating and giving off heat. Therefore, it can not be thin. Its average thickness is 6-7 cm.

For a warm floor, the coating is made of different materials. If you need to provide a quick repair of the premises, you can use a dry screed that does not require time to dry.

For a warm floor suitable wet screed on the basis of cement with sand and gravel. It takes a lot of time to dry it (up to 10 weeks). The composition of the cement mixture is recommended to add a plasticizer. It will help reduce the thickness of the layer, so the drying time will decrease.

Suitable for floor heating plaster screed. Due to its structure, it has good thermal conductivity. The thickness of its layer can be made less than wet.This screed is semi-dry, for its preparation does not need a lot of water. It will dry in 2-3 weeks.

Optimum conditions for drying

The quality and durability of the screed depends on the conditions under which the screed takes place.

It is necessary to ensure constant conditions of indoor microclimate:

- Do not make drafts and do not allow direct sunlight to fall on the drying screed.

- The best is considered the temperature of 20-25 degrees C. The temperature drop is not allowed.

- The level of humidity is desirable in the range of 60-75%.

Lower temperatures and higher levels of moisture lead to longer drying times. In winter, the installation procedure for the screed is undesirable; the minimum temperature at which work can be performed is +5 degrees. Uncured screed should not freeze. Central heating radiators must be turned off: they dry out the air.

Require special attention to the screed in the bathroom. As a rule, in these premises in modern block multi-storey buildings there is good ventilation. To prevent cracks in the freshly laid composition, you need to create a moist environment.

Sand or sawdust should be poured over the surface in an even layer, then they should be watered over the next 10 days. Moisturize the surface and in other rooms, if the weather is hot. To do this, you must regularly spray water.

Useful tips

Be sure to try to create optimal conditions for drying. Failure to do so threatens the formation of cracks and deflections. Not only the screed itself will deteriorate, but also the laid flooring. Before laying the topcoat make sure that the screed is ready. It will not be superfluous to check its quality.

Starting work is best in late spring, early summer.

If you make repairs in the fall, carefully monitor the long-term weather forecast and correctly calculate the time. The screed must have time to dry before the temperature drops below 5 degrees C. You can supplement the composition with special fillers that increase its resistance to low temperatures. The correct device of a coupler - guarantee of reliable and high-quality repair. Observe the accuracy of all technological processes.

In the next video you will find instructions for laying a semi-dry screed.