Floor screed with expanded clay: features and technologies

For a person to live comfortably in a private house or apartment, it is very important for a person to create the right microclimate. To this end, attention is paid not only to the environmental friendliness of the materials of the dwelling itself and its ventilation, but also to thermal insulation. Some people mistakenly believe that the floor will be warm without much effort, especially if it is made of wood. Nevertheless, about half of the heat from the room can “disappear” precisely because of improperly or insufficiently insulated floors and roofs, which in turn leads to increased energy consumption and the creation of uncomfortable conditions in the room.

A floor screed with claydite allows you to arrange floor insulation in any premises, moreover, knowing all the nuances of working with this material, you can safely carry them out yourself.

Material Features

Expanded clay - a building material that is made of clay suitable for these purposes rocks.It is dried, crushed, and then sieved many times to separate from other rocks and impurities. All these stages are important for the production of really high-quality material. Then the raw material is brought to the required consistency with water, and with the help of special drums balls of the required size are formed.

There they are burned in a special way in order to get a swollen mass. This is possible due to the technology of high-temperature drying, which is accompanied by the active evolution of gases. Expanded clay balls have unique characteristics due to the fact that they are filled with air inside and enclosed in a dense shell from above.

Despite the abundance of modern insulation materials used in floor screed, expanded clay continues to use to this day. However, not every type of building material is suitable for these works. The choice of a faction, as a rule, depends on the specific conditions:

- being near water;

- chosen method of laying (dry or wet);

- the required thickness of the insulating layer.

The material made in accordance with GOST does not pose a danger to human health. At the same time, some manufacturers neglect these requirements and manufacture products according to technical conditions, which may differ significantly from the norms accepted by the state. Such clayite often contains unacceptable impurities that can significantly increase the background radiation in the home and lead to disastrous consequences.

Therefore, before purchasing this building material, you should carefully read the documentation, clarify the manufacturer and product compliance with safety standards.

Grain fraction - a parameter that can significantly affect the physical properties of claydite and its scope. Here are the main types of this building material:

- Granules - gravel. They can have a minimum size of 20 mm and a maximum size of 40 mm.

- Ceramsite crushed stone with particle sizes from 10 to 20 mm.

- Sand from expanded clay turns out as a result of crushing of gravel on crushed stone and has particles less than 10 mm in size.

Only the first two materials can be used for floor screeding; sand is not suitable for this purpose. The fact is that the particle size is so small that it is not capable of creating an air cushion necessary for arranging effective thermal insulation.Such a claydite mixture in its properties differs little from a standard concrete pavement.

Advantages and disadvantages

Expanded clay screed for the floor does not lose its relevance due to environmental friendliness and availability of material. In an apartment or a private house, expanded clay is used for thermal insulation for flooring due to the following advantages:

- Allows you to raise the level of the floor (especially in the conditions of insulation of the subfloor in private houses and cottages) and prevents cold from the ground.

- It warms reinforced concrete floors in apartments, under which there are unheated (non-residential) premises.

- Excellent sound insulation of the room due to its porous structure.

- With irregularities and differences in the level of the floor in the room allows a very budget level the surface, especially in comparison with concrete and ready-made solutions for screed.

- It is inert to the formation of mold and rot, because it does not contain a nutrient medium for pathogenic organisms, and therefore, you can not worry about increased dampness and dangerous spores of fungi that can damage human health.

- It does not create an additional load on the floor, as it is a very lightweight material.

- It is not flammable, which means it can be used when installing underfloor heating.If there is a fire in a room with an expanded clay floor, then in the process of burning no harmful and toxic substances are formed. Also in such a coupler you can easily hide engineering structures and electrical wiring.

- Not afraid of temperature extremes. Does not lose its properties both at low and at high rates.

- Long period of operation. According to some information, expanded clay is able to retain its properties for 30-40 years.

- For the device of an expanded clay tie do not need special skills and sophisticated tools.

- Moisture resistant. The coefficient of water absorption ranges from 8-20%.

- Low cost and availability allows you to find this material in any, even a small town or village.

However, in addition to the obvious advantages, floor screed, made of expanded clay, has some negative points. Among them:

- In most cases, the thickness of the backfill with expanded clay is significant. As a rule, a layer of screed from this material with a height of less than ten centimeters does not show the properties necessary for heat and sound insulation.

- Dry screed, if moisture gets inside the claydite layer, it can significantly aggravate the indoor climate.In spite of the fact that the granules themselves are water-resistant, a concrete coating located above can be damaged.

Very often a mold and fungus forms on it, and in a dwelling the level of humidity increases. In this case, only the complete dismantling of the old screed and the installation of a new one can rectify the situation.

Before giving preference to a particular floor screed material, all positive and negative points are carefully weighed. In the case of expanded clay, plenty of advantages, and The disadvantages are conditional and are easily surmountable, while observing all the necessary standards for floor insulation work.

Kinds

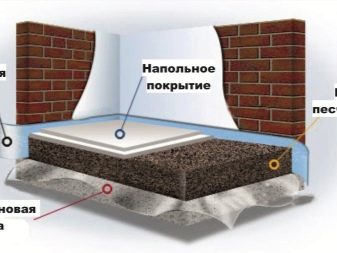

For screed floors in residential premises using expanded clay, including in new buildings, three methods can be applied:

- semi-dry;

- dry (filled floors);

- wet (claydite).

Each of these methods has its own characteristics and subtleties during the work. But always clean the base of the floor from debris and dust. If the floor has irregularities, then they are removed, and the old screed is also dismantled. For the purpose of waterproofing, bitumen mastic or special rolled material is often used that overlaps the floor. His sheets are interconnected with masking tape.

Semi-dry method

The semi-dry method is the only one that does not require scrupulous preparation of the floor for applying a screed. After cleaning the garbage, you can immediately get to work. If wires or communications pass under the floor, they are isolated and pressed tightly against the base of the floor. Installation by a semidry method consists of two consecutive stages:

- First, the floor is filled with expanded clay. It is important that its level be 2-2.5 cm below the future base of the floor.

- Then the floor is filled with cement mixed with water. After setting the granules between themselves, the surface is additionally filled with sand concrete and allowed to dry well.

Dry way

The dry method is very popular because it is the simplest, does not require the purchase of cement. For the device of such a screed, the previously prepared floor is covered with a vapor barrier film, and the necessary layer of expanded clay is poured onto it and carefully leveled using a level. Top stacked slabs GVL.

Wet way

The wet method involves the independent manufacture of expanded clay. You can also buy ready-made mixtures, for example, companies "Vetonit". Buying a ready-made expanded clay mixture facilitates the work, but it should be borne in mind that it hardens much faster than self-prepared claydite-concrete.

The ratio of the components of the self-prepared solution individually, it depends both on the quality of concrete and on the characteristics of the room where the installation of the screed will be carried out. The solution is poured between pre-installed beacons and carefully leveled.

However, it is sometimes difficult to achieve a level surface, therefore, quite often an additional thin layer of concrete is poured over such a screed, which levels the roughness of the subfloor.

Whichever method is chosen, it requires strict adherence to the stages and technology, and then a high result can be achieved.

Device

Depending on the technology, the following tools and materials may be needed:

- building level, better laser;

- steam-, hydro- and noise insulation;

- concrete or ready-mixed concrete;

- expanded clay;

- water;

- concrete mixer;

- broom or construction vacuum cleaner;

- trowel;

- garbage bags;

- shovel;

- self-tapping screws;

- glue;

- drill;

- vibrator;

- lighthouses;

- the rule;

- masking tape;

- construction knife

Before you start installing the floor screed in the chosen way, you must carefully prepare the room:

- The surface is dedusted, construction debris is collected in bags and taken out.

- Next, using the trowel dismantled the old screed.

- If the screed is laid on concrete, the base is inspected for chips and cracks. Defects are closed with a cement mixture. Without repair, it is impossible to achieve a good end result.

- Next, set the beacons using the level. Subsequent actions depend on the screed method using expanded clay.

After the work is completed (or after the required time has expired), the beacons are removed and the surface is leveled with concrete. The longest time is required for the screed, which was arranged by the wet method, while the dry method allows you to immediately begin the installation of the finishing coating (parquet, linoleum, laminate).

Mounting technology

Each of these three methods of floor insulation using expanded clay has its own, unique steps and features.

When constructing a screed using the dry method, the sequence of actions is as follows:

- On the prepared floor with overlap fit vapor barrier film. Sheets should come at each other by 20 cm, and at the edges of the walls - 6-7 cm. The film is interconnected with masking tape. The edges of the material on the walls are covered with edging tape.

- Screws are screwed in the upper points of the floor surface, their tops are covered with cement mortar. Its quantity should provide an even arrangement of the slats, for this they are checked by level.

- Lighthouses are mounted on screws. They can serve as a smooth wooden bars of a suitable size or metal profile.

- A layer of expanded clay is poured into a prefabricated structure. It should not be less than 10 centimeters. Dry screed is leveled using the rule.

- The layer of expanded clay is carefully tamped by hand or using a vibrating machine.

- Rammed areas are closed with two layers of gypsum fiber board plates, as well as using penoplex. In some cases, the use of expanded polystyrene is justified. To bond them together, you can use glue or screws. If self-tapping screws were used, the holes from them and the seams are carefully puttied.

- The protruding edges of the film on the walls around the perimeter of the room are clipped.After that, you can proceed to the installation of the main floor.

When using the semi-dry method, the sequence of actions is as follows:

- Waterproofing is carried out using special materials or plastic film with a thickness of 2 mm. Joints are taped with masking tape. It is important that the edges of the waterproofing went on the wall for 10 or more cm. With self-tapping screws, the level and wooden bars are installed beacons.

- The layer of expanded clay is filled up. At this stage, you should pay attention to the unevenness of the floor level. If they are, they will be eliminated later in the process of applying the finishing screed. It is important to ensure that the level of expanded clay filling is 2 cm lower in relation to the lighthouses.

- Prepared cement milk. In order to prepare it, sand concrete is brought to a homogeneous liquid state with a consistency resembling milk. The resulting mixture pour a layer of dry expanded clay. After that, the surface is allowed to dry for a day.

- After that the draft floor is filled with a coupler. It consists of 3 parts of sand, 1st part of cement, water. The required amount of water is indicated on the packaging of the cement used.

- Concrete leveled rule. The level of the tie must pass along the edge of the beacons.

- At the end of the day, which is necessary for setting the screed, the beacons are removed. The places where they were, filled with mortar and level. After 14 days the coating is ready for laying the main floor.

Despite the fact that after two weeks the screed is ready for installation of the topcoat, it cannot withstand constant loads. It is possible to use the room safely, including installing furniture, only after 28 days.

In the wet process, the screed also has two layers. The stages of work with the use of expanded clay consist of the following steps:

- After laying waterproofing exposed beacons.

- Prepared clay solution. The following proportion is observed for this: three parts of sand, one part of cement and the necessary amount of water are added to eight parts of expanded clay. All components are poured into a concrete mixer and thoroughly mixed.

- The resulting mixture is filled by beacons. "Underfilling" to the wall should be 2 centimeters.

- In a day, a sand-concrete finishing screed is applied.

- After 2 days the coating is ready for laying the main floor.

According to some technologies, you can not wait for the expanded clay layer to grab, and immediately arrange a finishing screed.

Professional Tips

Despite the simplicity of the technology of floor screed using claydite, you can significantly complicate your life if you do not follow the recommendations given by professional builders:

- If there are communications on the floor, especially electrical wires, they should be carefully isolated. Otherwise, a short circuit and an accident may occur.

- Waterproofing should not be neglected - it should be performed without gaps and defects. An incorrect device of this layer will significantly shorten the life of the thermal insulation made of expanded clay and may lead to a violation of the indoor microclimate.

- The surface on which the screed will be placed should be dry and free of debris and dust.

- If there is an opportunity to rent a vibrator - then you need to use it. This unit compacts the cement layers and removes excess air from them, which reduces the density of the finished screed.

- It is possible to add special improvers that enhance the screed. They can be purchased at almost any hardware store.

- The finish screed is covered with plastic wrap and moistened daily.This "watering" is needed so that the concrete is not covered with cracks and does not begin to peel off from excessive dryness.

- It is forbidden to give a load on the screed made using the semi-dry and wet methods earlier than 28 days.

- Carefully follow the technological recommendations on time, depending on how much each of the layers of expanded clay screed dries.

Following these recommendations, you can avoid most of the problems that may arise during the laying of the screed, and during operation.

Expanded clay - one of the most popular materials, which, despite the abundance of more modern building materials, does not lose its relevance. Screed for the floor with their own hands using claydite allows not only to save money, but also to improve the indoor climate. One of the main conditions for success is the right choice of material and method of floor insulation. Properly arranged insulation will last more than a decade and reliably protect the floor from dampness and mold, create a comfortable temperature and humidity in the house.

For more information on how to screed with expanded clay, see the following video.