Cement floor screed: consumption per 1 square. m

In the process of repairing an apartment or a private house, an important step is to prepare the base of the floor - laying the screed. The most popular and well-known cement floor screed. If you decide to do the repair yourself, you probably wondered what kind of mixture to buy, how to calculate, how much it will be needed.

Special features

Cement screed does not lose its relevance due to the fact that it fits under any clean floor. It is made from a mixture of cement and sand and diluted with water. Then the resulting solution is poured into the room. This method is known as “wet.” The reasons for the popularity of this type of screed:

- Availability. Ingredients or ready-mix can be easily purchased at any hardware store.

- Coating strength.A sufficiently thick layer (as a rule, more than 20 mm) ensures reliability and durability of the floor.

- The ability to isolate sound. In modern apartment buildings this quality is extremely important.

- Suitable for the device "warm floor". Nowadays, in private houses, bathrooms of apartments often resort to the use of floor heating technology. It is convenient and practical. Electric or water heating systems can be easily and safely “hidden” in the cement layer. In addition, it has good thermal conductivity, and the heat loss will be minimal.

- Pipes and other communications can also be hidden with a cement screed.

- After drying, the layer is practically not deformed, does not shrink. You can not worry about its integrity.

However, there are several negative points:

- work is hard and hard. Beginners will not be easy to cope with the laying layer;

- the solution is not suitable for old and wooden floors because of the large weight;

- if you require minimal deviations for a decorative floor, then you will have to lay a leveling layer of another mixture on the cement screed;

- the usual solution dries for a long time, it requires maintaining constant humidity.

It is also necessary to ensure the absence of drafts and temperature drops in the drying process.

Varieties of solutions

The variety of types of screeds in the construction market is constantly growing. The basis of the composition is sand. Best of all, when it is cleaned, white, without admixture of clay. The presence of clay in the composition can lead to the loss of high strength characteristics of the future screed. Various additives and plasticizers are developed, with the help of which certain desired properties and characteristics of the mixture are achieved. The second main component in the solution is cement or gypsum.

The cement-added mortar is durable, such a screed can be used in rooms with high loads. The mixture can be used at high humidity. The cement is budget, so it is widely demanded, but it needs to be laid in a layer of 2 cm, otherwise the desired effect will not be achieved. In the case of gypsum work is somewhat easier. The surface is smoother. The layer can be thin, up to 2 cm, while the strength and resistance to stress will remain high.

The mixture dries quickly, does not shrink. A significant drawback is intolerance to moisture.

There are three types of cement screed that can be laid indoors.

Bound

The name itself suggests that the screed is connected to the base. There are no layers between the floor slabs, walls and subfloor. This method is used if it is necessary to achieve a layer thickness of no more than 40 mm. The base must be carefully prepared. All cracks and chips need to be repaired with a repair solution, minor irregularities can not be eliminated. Before laying the associated screed, the surface is treated with primer for better adhesion of the cement mixture to the base.

The mixture is diluted to a consistency of thick cream, then immediately poured onto the floor surface. After 20 minutes, the screed begins to harden. This process is really long, therein lies a big minus of the method. If a large surface is processed, then working alone is not possible.

Unrelated

Here the layer may be more than 40 mm. Under the screed must fit waterproofing. This will protect the ground from moisture penetration during the screed filling, and the draft layer from moisture coming from outside (for example, if the floor is made on the first floor of a "high-rise building" or in a private house).

Floating screed

It is placed on a heat or sound insulating layer. Its thickness may be different, but when a height of 3-4 cm is reached, reinforcement may be necessary.

Depending on how much water is added, the screed is divided into wet and semi-dry. Wet screed is a well-known and widely used method. Thus, the coating should be carefully dubbed, and waterproofing should be used so that moisture from the mixture does not absorb into the base and does not deteriorate the strength characteristics.

Semi-dry screed is obtained due to the fact that the rate of water is reduced. The composition has a porous thick texture, similar to sand mixture. It is easier to align, and there is no risk of flooding the neighbors.

Cement screed, in contrast to the concrete, is used exclusively in the premises, although the screeds of concrete are also made on the basis of cement and sand mixture with the addition of different fractions of additional materials. In terms of cost, they practically do not differ. There are two ways to prepare the cement screed:

- Dilute ready-made mixtures, which are sold in large quantities in hardware stores. You only need to study the instructions,add the right amount of water and stir the mixture with a construction mixer. Cement mixes of the Knauf, Bergauf, Perel, Hercules, and Prospectors brands are widely known. Pack the mixture in bags of 25 or 50 kg. Such packing is more convenient during transportation, because the cement is quite heavy. Ready screeds have a lot of advantages over homemade. Various plasticizers can be added to improve strength and speed up drying.

- Prepare the product yourself from cement, sand and water. In this case, you need to carefully approach the choice of brand of cement, to observe the proportions of water and sand in the solution. The numbers in the cement labeling (M200, M400, and so on) show the maximum load it can withstand. For apartments suitable brand M150 and M200.

The importance of proportions

If only water is added to the finished dry mixtures, the required amount of which is indicated on the package, then when preparing the solution yourself, the proportions are not always maintained perfectly. Extremely important compressive strength. Above, we mentioned maximum loads and cement markings. So, M150 cement withstands a load of 150 kg per square centimeter, its compressive strength is 12.8 MPa. The higher the mark, the greater the strength.In cases where they do not specify a specific brand, they are guided precisely by the M150.

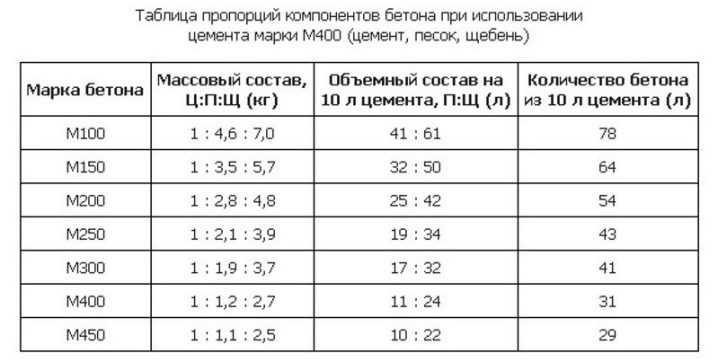

To perform a screed in the apartment, it is advised to use cements of marks M400 and higher.

The quality of the sand also affects the overall characteristics of the mixture. For high strength and quality characteristics of the cement screed, it is better to use sand with an impurity content of less than 5%. In the event that you use more polluted sand, the final result will become completely unpredictable. After acquiring sand, you can be sure of its reliability by adding some of it to a bottle of water. If after stirring the water gets a muddy brownish tint, then this sand should not be used.

If for some reason you are still not sure about the ingredients, it is advised to increase the amount of cement by 20%, reducing the volume of water. The importance of respecting the proportions will affect the strength, moisture and heat insulation characteristics of the screed. The ratio of sand and cement also depends on the expected maximum load on the screed. For flooring in non-industrial premises, as a rule, DSPs are made on the basis of М150 or М200.M400 cement and sand are taken in proportions of 1: 3 or 1: 2.8. Water is added in the ratio of 0.45-0.55 per 1 m2.

It is necessary to ensure that the solution is homogeneous, does not spread and does not exfoliate, does not have clots. This is important to preserve the strength of the screed. When using more water, the screed will be too liquid, it will harden for a long time and will lose the necessary technical parameters.

What affects the consumption

The calculation of the required amount of solution is usually done on the basis of the consumption per square meter. This expense is affected by many conditions, so there is no single calculation mechanism. There are several factors that influence the amount of ingredients in a mixture:

- builders know that the quality of the screed affects the shelf life of cement, so it is recommended to use powder released no more than 6 months ago, otherwise the strength of the coating will be reduced by at least 10-15%. If the cement is older, then for the safety net its share is increased.

- Base irregularity is the main factor affecting the increase in the consumption of the mixture. It is not enough to know the surface area to be filled. It is necessary to take into account that in the presence of deep cracks and strong surface differences the consumption increases by 50%, therefore, measurements should be carried out in several places.

- To save cement, various large fractions like claydite or crushed stone can be added to the mixture. This turns the solution into sand concrete and can significantly change the properties of the coating.

- The amount of the mixture directly depends on the type of tie. In those cases, if it is unbound or floating, the height of the coating is more than 4 cm, so the consumption of materials increases.

- The brand of cement and the purpose of the mixture obtained affect the ratio of dry powder and sand.

- Laying communications - another condition that can greatly affect the flow of the mixture. The diameter of the pipes serves as the main factor for increasing the volume of the mixture. Layer screed over communications can reach 5 cm in height.

- If a technological bias is set (which is important for a bathroom), then the drops also need to be included in the calculation of the finished mixture.

- If you want to achieve not only the savings of the DSP, but also increase the thermal insulation characteristics, it will help not only the addition of large particles, but also an increase in the height of the mixture. Wet screed with expanded clay to preserve heat should be laid with a layer of not less than 10 cm.

Nuances of counting

When performing calculations should pay attention to the following points:

- The purpose of the room should influence the choice of component brands and the composition of additives. For warehouses, industrial premises with a large load, you need to choose cement with higher rates to increase floor strength.

- If the draft coating needs to be laid with a layer of 80 mm, then the use of sand concrete will be efficient.

If high loadings on the coating are not planned, then it is possible to mount a DSP with a reinforcement mesh.

- When installing a finishing coating, the thickness of the screed usually varies between 5-30 mm. For this type of screed is better to choose self-leveling compounds.

- When making a semi-dry screed, you need to consider that the volume of water will be reduced in order to obtain a cement-sand mixture of the required consistency.

- When building a "warm floor" layer of the screed above the pipes or network of electrical wires should not exceed 80-150 mm. A thicker layer will significantly reduce the thermal conductivity of the screed and the effectiveness of the entire system.

- In old multi-storey buildings, when laying a new screed on top of the old one, it is necessary to take into account what maximum load the ceiling can withstand.

Expense calculator

Due to the fact that the proportions, quantity and type of ingredients for the screed are influenced by many factors, there is no single formula for the calculation. So, for living quarters, it is customary to knead cement with sand in a ratio of 1: 3. Since some rooms have increased loads (for example, in the kitchen, hallway, bathroom), the M200 is preferred for the final mixture for the floor. To obtain it, cement M500 is required. Approximately 0.5 liters of water is taken. It is best to determine its optimal volume in the process of mixing, since too thin a solution can reduce the quality of the screed. The volume of the mixture for a layer of 1 cm is calculated on the basis of:

- the length of the room;

- its width.

The result should be increased by 20% due to shrinkage of the cement-sand mixture. For solutions of their own preparation, it is usually necessary from 14 to 21 kg of mixture per 1 square meter. m rooms. For a thicker layer, calculations should be made on the basis of its thickness. For example, take a room of 10x10 m and the desired height of the screed 5 cm. We take for filling the cement grade M400 to obtain the final mixture M100. The ratio of cement and sand in this case is 1: 4.

- The total volume of the mixture: 10 * 10 * 0.05 = 5 cu. m

- The amount of water will be approximately equal to half of the total volume, so 5-2.5 = 2.5 cubic meters will be required. m dry mix.

- Based on the ratio of 1: 4, the cement will need 0.5 cu. m, and sand - 2 cu. m

- Cube m cement weighs about 1300 kg, cubic meters. m of sand - 1600 kg. At 100 square meters. m area you need 1300 * 0.5 = 650 kg of cement and 1600 * 2 = 3200 kg of sand.

- So, for 1 square. m screed thickness of 5 cm will need 6.5 kg of cement.

- In bags, usually 50 kg. Therefore, the entire area needs 13 packs.

Master class for pouring floor screed, see below.