Manifold for underfloor heating: features of choice and operation

Underfloor heating requires not only to put the pipes under the floor covering, but also to use additional technical means. A prerequisite for the successful operation of this design is the use of manifolds, pumps, sensors and valves. All these elements of the system deserve a separate discussion, and now we will talk about collectors.

Special features

The device, called the collector, is a complex of parts designed to direct the coolant, mixing it, to supply fluid in parallel circuits. A significant cross section and a drop in the flow rate ensure the fusion of the hot coolant coming from the boiler or the central heating system to the cooled one that has returned from the heating circuit. As a result, the temperature levels off.

But the correct mixture of hot water and reverse flow is achieved Only when using at least three sensors:

- Water temperature indicator.

- Outdoor temperature meter.

- Pressure gauge.

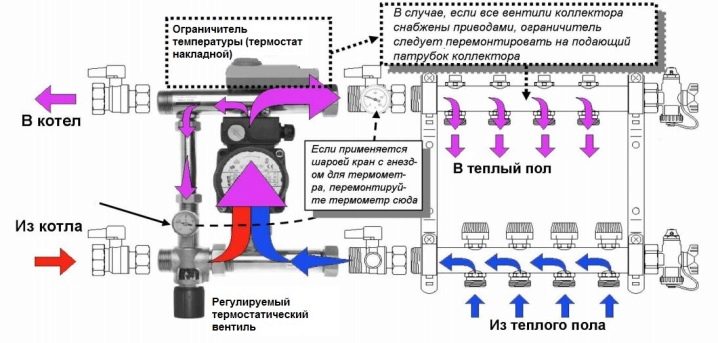

The signals of these sensors, and, if necessary, others, come to the valves that mix the coolant. Switching valves from one mode to another directly affects the heating of a heated floor. Collectors necessarily join the pumps. Temperature control depends not only on the weather outside the window, but also on what purpose water is needed. So, in the shower cabin it should be supplied heated to 70 degrees, the temperature in the radiators is even higher, and heating of the floors requires the use of heat carrier not hotter than 50 degrees.

Even the best boiler cannot provide such gradation, and therefore the collector group works with it. Her role is also in that to normalize the pressure in the elongated circuits, to quickly control the pump. The comb is often installed not one, in this case they should be connected not only with the central collector, but also among themselves.

If you want the size of the collector unit to be minimal, do not assemble it yourself: branded devices are much more compact and must be equipped with air vents.Install them manually at home is unlikely to succeed.

Kinds

Collectors are divided primarily into feed and return. The first type is usually mounted on top, the water passing through it evenly diverges through the loops. Of these, the liquid then enters the return part, returns to the boiler, and so on without end. If you look at the functionality, you can find four main groups of reservoirs:

- The description of the simplest of them is not difficult: it is just a pipe that has been cut inside and out to connect external pipes. In the plumbing of such a device is enough, but the warm floor is more complicated and will require the use of additional elements.

- Manifolds with valve installation directly at the outlets are very common, they differ in quite good performance. But the quality of water in most areas of the Russian Federation is not designed, even if the ball valves themselves and high-quality, soon they still begin to leak. It is necessary to change the sealing rings regularly. A serious drawback is the inability to install devices that regulate the temperature in automatic mode.

Often, a European-made mixing module can only be connected via adapters, since such products are made by little-known Asian factories, standards are not deliberately taken into account.

- It is easier to set up more expensive collectors, because the ball valves are replaced by full control valves. Servomotors on the valves are connected to thermostats located in different rooms, which ensures the most rapid response to changes in temperature. Say, when a festive dinner is prepared in the kitchen, the heating is reduced, and if in the late autumn airs the room, opening the windows and doors in the room wide open, it should be strengthened. Fittings for connection to metal-plastic pipes are prefabricated structures formed by a cap nut, a compression ring, an euro cone and sealing parts.

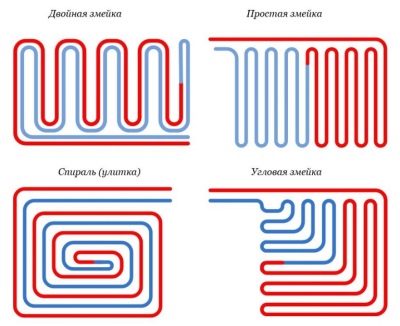

- All three previous types perform well if the contours are more or less the same. But with a significant difference in their length, it is worth choosing collectors, which are equipped with flow meters in the feed segment, while on the return segment - with sockets to hold the servo drives.It is categorically not allowed to install the return manifold at the top, but rather to pump it downwards, since this will lead to the heating of the return flow with part of the heat in the original pipe. As a result, less heat will enter the room itself.

Collector Details

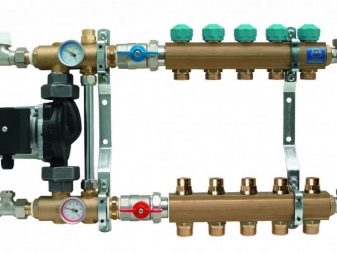

The performance of its functions collector provides for the expense of the work of a number of elements. The purpose of the mixing valve is quite understandable; it ensures the fusion of water with different temperatures. The pump controls the pressure, if necessary increases it. The system also uses locking and balancing valves, a device for dumping accumulated air, pressure gauges, a thermal head with an integrated thermometer, and a number of plumbing connecting parts.

We will now deal with them carefully:

- Combs combined with the mixing unit of two main types: one has two moves, the other three. The two-stage operation scheme implies that the thermal head measures how hot the heating medium moves towards the contours. If a certain value is exceeded, the valve slightly closes and the flow of hot fluid decreases.Otherwise, when the water is too cold, the hole opens stronger, the influx of heated fluid increases. Although the valve lets in relatively little water, it is rather an advantage - the floor can heat up more smoothly. It is recommended to connect the mixer to the comb not directly, but by means of a collapsible coupling, in order to simplify the replacement later.

- Three-tier system it is arranged differently: both the hot and the returning flow are regulated simultaneously; for this, a bypass is built into the collector node. The valve is not simple - it hides a special valve, standing at a right angle to the cavity of the mixing tube. By varying the position of this valve, the equipment sets the heating level of the heat carrier at the outlet.

This solution is recommended for use in large houses with an area of over 200 square meters. m, when the throughput of the two-way valve is no longer enough.

- MixersHaving three strokes is also advisable when the collector adjusts the temperature automatically, and not according to the manually specified values. The valve does not work by itself, it is assisted by a servo, in turn, coordinated by the indications of weather and temperature indicators.With all the advantages, the three-way system has a weak spot: it works too abruptly, and it is worth only slightly changing the position of the valve so that the temperature rises strongly or instantly drops.

- The role of weather sensors is invaluable: even if the temperature on the street changes significantly during the night, the equipment will automatically switch to the desired mode. Try to buy all the elements of the construction of the water floor as a whole, or at least the details of the collector itself from one manufacturer. When assembling a knot by yourself, choose a uniform material for all parts, so it will be safer and more stable.

Pay attention to the number of heating circuits, the total length of the pipe path and its throughput.

When selecting parts, be also interested in the maximum allowable pressure, the ability to expand the heating system and make it stronger, the diameter of the holes in the manifold. The distribution block has another important characteristic - the number of outputs. Accurate counting of the number of loops (contours) is not always possible, because part of the premises will require to install two loops at once.

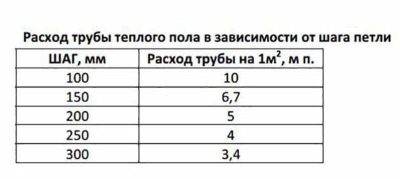

A preliminary calculation is made on the assumption that on 1 square.m heated floor area will account for 6.5 pog. m pipe. Match the resulting figure with the lengths of pipes in coils, and then it becomes clear whether there is no need to do two loops at once, so as not to throw out in vain expensive designs. Acquiring an extra collector circuit (later silenced) is more practical than adding it to an already assembled system.

A collector with a pump is recognized by all specialists as the most effective solution compared to others. Forced fluid circulation ensures reliable heat supply to all parts of even a very large house. Maintaining the necessary bias for natural circulation is extremely difficult, especially when this consideration contradicts other technical requirements and nuances.

Collector assembly

When all parts are available, you can assemble a collector. The cabinet for mounting the mixer can be external and internal, but in the first case only the system can fit no more than 160 cm wide. We recommend that you carefully study the installation scheme and not shy away from it, even if a step seems senseless and ridiculous to you.

The equipment with flowmeters allows to achieve a uniform movement of the coolant; if somethough the loop is not much shorter than the others, the water rushes into it, since the hydraulic resistance is lower. Flow meters just allow you to reverse the effect of this physical pattern. This is much more practical than using manually adjustable systems.

A home-made collector may not include a mixing unit, then the installation of valves is not required, a stable temperature is maintained by one circulation pump. It is mounted strictly in the return pipe so that the excess volume of fluid from the heating system is not dragged out. When using two-way systems, the binding includes the installation of a pair of valves on the return pipe, this will eliminate the situation when a reverse stroke occurs. If a low-temperature convection boiler is installed, there is no particular need for a collector; but if you want to use weather automatics, you can’t do without it again.

The plastic collector is no worse than the metal counterpart; moreover, finding craftsmen who can assemble a polypropylene comb is not difficult.For durability and reliability, stainless steel and brass pipes are considered the best solutions, polypropylene works reliably only in two or three simple contours, which must be taken into account during installation. All experts recommend choosing an industrial collector assemblybecause the solid product is much more stable and less risk that it will begin to leak.

Although they say that the straight ligament is the simplest, sooner or later it will still have to be redone to a two-way or three-way, so it’s better to do it right away.

The lightest scheme includes a bias valve (plumbers call it “three quarters”), an adapter, an “American” type coupling, a ball valve, a manifold, bundles with external and recessed threads (all for the same inch). In addition to these parts, you will need nipples, tees, elbows, circulation pumps, an air vent and a drainage valve. The assembly of multi-circuit warm floors requires the use of a thermal head with a sensor placed outside, a valve for mixing the liquid.

Also in the complicated system “American” ¾ is used, several nuts of the same size, tee and nipple (both inch).½ inch valves are connected to the circulation pump, the fitting and metal plastic pipes have the same dimensions. The cap is used inch, in a collector establish spherical cranes of 0.5 inches, nuts for fastening of the pump - nakidivaemye.

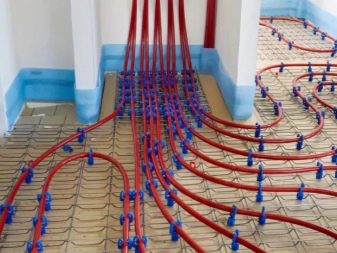

Connection of warm floors to the collectors is made on the crimped fittings. Before the joint, a chamfer is formed in the pipe, due to which adhesion is improved. When all work has been completed, the pipes are pressurized and tested in the operating mode (with a deliberately increased pressure). The test duration is 180-300 minutes, the temperature is set to maximum, to be guaranteed to identify all weaknesses and shortcomings. The collectors are placed in special cabinets, installed either directly at the boiler, or near the connection point to the heated floors.

Instead of a collector cabinet, a sufficiently capacious niche can be used. But this is permissible only after consulting with professionals, ideally, they should be trusted with such work.

Independent installation not according to the scheme has serious consequences, malfunctions and even flooding!

How to connect?

If the heating system has 2 circuits, it is necessary to make every effort so that their length is approximately the same. Combined with the use of distribution manifolds and some other special devices. ensures a uniform degree of heating of all rooms. Or, as experts say, the balancing of the heated floor has been carried out. This procedure requires a thorough thermal calculation, the main parameter at which is the volume of all branches. It is calculated how much it is necessary to limit the inlet of water to each circuit for uniform heating.

Tuning also means taking into account the number and radius of turns in all the loops, because they increase the resistance of the system to the passage of fluid. If there is already a heating system installed in the house and there are no standard mechanisms supporting the balance between the circuits, it is necessary to install balancing valves. The difference from simple shut-off valves is the ability to regulate the flow of coolant in an automatic or manual way.

Heating a single room of no more than 25 square meters.m powered by water from radiators can mean both manual and automatic (using a thermostat) control circuit. In such a system, it is better to supply water to a strongly heated circuit and to receive a reverse flow of coolant through the “American” sample tap.

If the automatic adjustment is carried out using a thermal head, the mixing valve must be installed so that the “+” sign indicates the exit from the main valve. The valves supply water to the system and the pipes returning it to the collector are fastened through connecting elements with external thread. The circular pump should pump fluid in the direction of the mixing valve.

Tips for choosing

Pay attention to the following nuances:

- The simplest system, which regulates only the supply of warm floors with a coolant of uniform length, can be controlled by manually closing and opening taps. If the equipment is connected to radiators, it is recommended to use manifolds equipped with duct sensors; It is desirable to use devices with servos.

- Components are quite important, moreover, any; When choosing valves, be guided by empirically established data.If the water flow per hour does not exceed 2 cubic meters. m, such devices will be able to provide heating from 50 to 100 square meters. m floor. But note that the upper figure is more indicative, can only be achieved with a solid insulation, a powerful boiler. Very cold weather also reduces the effectiveness of the system.

- Floors from 80 to 200 square meters. m efficiently heated using collectors with a capacity of 2-4 cubic meters. m per hour More powerful systems are not recommended, because it is easier to mount a pair of mixing units. As for valves, take only brass or stainless steel samples issued by reputable companies.

- Pay attention to how the water temperature is regulated. In the middle zone of the Russian Federation and in the more southern regions, the normal temperature is 30 degrees minimum and the maximum value is 55 degrees. If you live north or just the floor is not warm enough, it is recommended that both values be increased by 5 degrees. Consider these circumstances when you complete the system and mount it.

- A special box for installing a collector, most often has dimensions of 600x400x120 mm. It should be placed strictly at the edge of the floor covering, it is undesirable to raise this device higher.Many manufacturers try to produce such steel products with a corrosion-resistant coating or polypropylene in order to eliminate the risk of rusting when in contact with water. You can choose either a reduced or an enlarged cabinet compared to typical dimensions if you need it to accommodate a specific collector and associated equipment.

- Wall collector cabinets are mainly painted with white powder paint, while the built-in versions only have a front panel. If there are small children in the house, it is advisable to equip the collector sites with reliable locks that prevent random access.

Manufacturers

Russian collectors for warm floors are made of stainless steel, they are equipped with all the necessary attributes for successful work. European products are also automated as they should, but they are mainly made of ferrous metals. Masters appreciate products from Rehau, especially the fact that it is very convenient to attach the pipes to each other, the supply and receiving connectors are mutually distant. Do not expect that you can buy a very cheap collector and limit it, almost certainly you will have to purchase a lot more.

Corporation Valtec produces high quality collectors for underfloor heating, equipped with air spreaders, drainage devices, end caps. The company values its reputation, and therefore each product is subjected to rigorous quality control at various stages of work. Everything that is officially supplied to the Russian Federation meets national standards and provides 100% of the customer’s needs.

The company promises that the installation of collector systems will cost a minimum amount of money and will be quite operative.

In the field of plumbing and plumbing equipment, Italy has an unquestionable authority that manufacturers of collectors, such as Luxor, Fado, Caleffi and some others. The maximum working pressure is 10 bar for the equipment of these brands, the highest permissible heating is 110 degrees (for individual modifications 120, but it is better to clarify this with the technical documentation).

Concern "Millennium" arranged supplies of excellent collector groups with thermostatic valves, mixing blocks. Modern Chinese company completely refutes the very fact of the existence of its products myths about the low quality of Asian products.For the manufacture of collectors in the factories of the "Millennium" used first-class stainless steel, the highest operating temperature is 80 degrees. It is quite enough for distribution of water in any system of a heat-insulated floor.

Successful examples and options

It remains to find out some details about successful solutions when placing a collector of a heated floor. After all, it is not enough to choose it, you also need to mount it correctly. Basically, distribution points are placed at similar distances from parts of the pipeline, this facilitates the preservation of uniform operation. If such a requirement cannot be fulfilled, it is better to install a pair of collectors, giving 50% of the heat load to each.

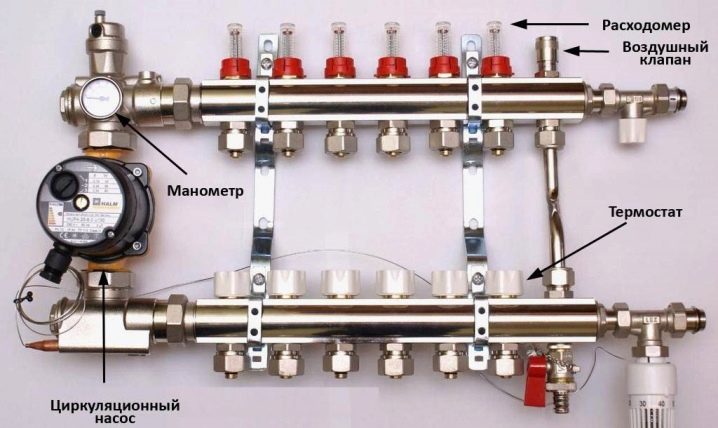

A typical arrangement of elements is shown in this example. Nine circuits have been connected to the collector, to the left of it are a valve, a pressure gauge and a thermometer.

This scheme can also be considered successful, it also presents a flow meter, a thermostat, a compact circulation pump.

How to install a collector, see below.