Floor heating: the subtleties of choice

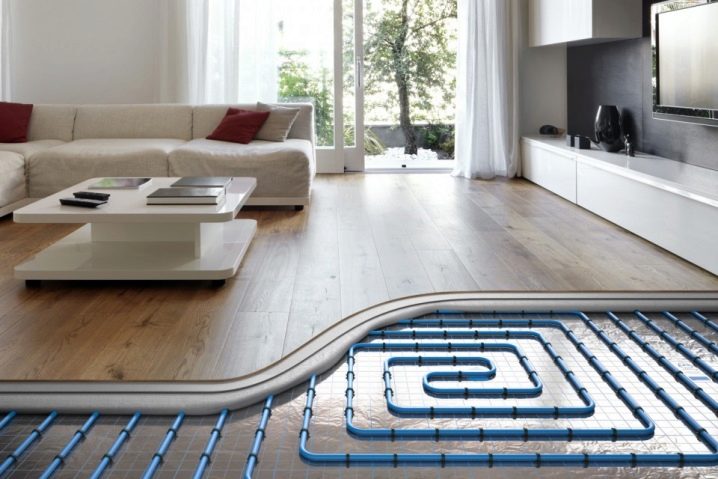

Heating the floor with water is fundamentally different from its electric heating, both methods have strengths and weaknesses. In order for a water-heated floor to be as efficient as possible, you need not only to install all of its components in a certain order, but also to correctly set up the system and choose a good boiler.

Even floor screed and waterproofing are of great importance for the normal operation of such a system.

Special features

In most cases, warm floor is preferable for owners of private housing, but not for apartment owners. It works well when you need to warm up the whole house, but if you only need to warm the floor in a separate room, it’s better to use electricity. It is easier to lay the cable in a small (up to 20 sq. M.) Space than to install pipes there, complementing them with the necessary control equipment.

Heating the floor by supplying water from the central heating system is unacceptable.so that the neighbors' batteries are not cold. Even if you equip the system, tying it to a separate heating circuit, you will need to coordinate this with the building inspection. Compared with the use of radiator heating facilities, underfloor heating allows you to evenly heat the house, the distribution of air temperature is physiologically comfortable.

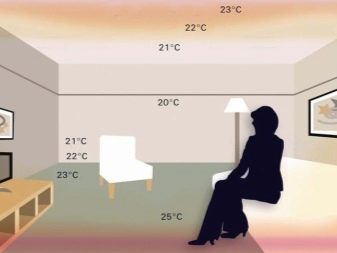

In both heating schemes, the air around the heater is primarily heated. But since radiators are local sources of heat, the maximum temperature is reached near them, at the windows and near the ceilings. There it is from 25 to 40 degrees, and this is a necessary condition for the average heating in a room to be 20 degrees.

The contours of the warm floor are evenly distributed in all parts of the room, which can and should be heated, so using it is much more economical. By reducing the temperature of the coolant by only 1 degree, reduce the consumption of thermal energy by 8% on average, eliminating local overheating and heat loss through the walls.

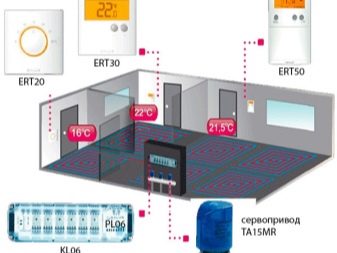

The device of radiator heating does not allow the use of automation, which sets different temperatures in certain rooms, especially in their parts. But the use of a heated floor just allows you to set your own parameters for each circuit. The service life of water-heated floors (more precisely, polymer and metal-polymer pipes laid in their base) is over half a century.

Among the reasons why water underground heating can fail, should be called illiterate installationIn this sense, it is much more demanding than other structures.

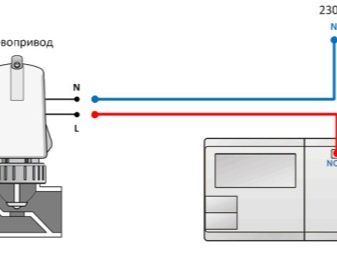

Finally, due to the long length of the pipeline and sometimes very complex forms, servos will necessarily be used.

Advantages and disadvantages

The undoubted advantages of a water heated floor are not only the uniformity of air heating, but also:

- Ecological purity;

- No noise;

- Maintain a good microclimate;

- Preservation of rational, physiologically reasonable humidity;

- Elimination of dust and accumulation of dirt in the apartment;

- The uselessness of bulky parts and elements.

But not to mention about the disadvantages of water-heated floors.Mount them hard enough, consumables cost considerable money, which will have to invest immediately. It will be necessary either to install a condensing boiler, or to use a mixing unit, which will allow to reduce the temperature of the coolant. Note that technology over the past few decades has gone far ahead, and water heated floors are completely not subject to hydraulic shock, corrosion processes. Significantly less likely to leak.

But nevertheless only such a construction works well, which is selected, assembled and configured in full accordance with the basic principles of heat engineering. Sometimes very complex calculations are required, especially if the contours are of complex shape and have many turns. So in such cases, high-level specialists should design and create a system, while it is possible to install an electrical cable using one's own resources.

Warm water floors do not increase the dampness in the room, but if the room is already characterized by low humidity, prolonged heating can dry out the air. In the bathroom it is not relevant, it is even to some extent an advantage, but in other rooms it is necessary to air more often, to put indoor plants, aquariums, or to apply moisturizers. remember, that Under floor heating badly affects furniture and musical instruments made of natural wood. Where such objects will stand, there is no room for the heating circuits! In addition, you should not drill the floor in which the pipes with water are hidden; as a last resort, check each action with the layout of communications.

The absence of electromagnetic radiation can also be considered an advantage of water heating. However, it should be noted that electromagnetic fields arise when the control automation, pumps and some other system components work.

Always ask whether these devices meet basic requirements and safety standards, whether they have the necessary certificates and licenses.

The installation process, even when relatively simple semi-dry screeds or panels are used, is rather laborious and long. The slightest mistake during installation can turn into serious negative consequences, breakthroughs, so it should be dealt with carefully. Not all floors can withstand the load created by a water-heated floor, and this is another reason why it is not always reasonable to use it in an apartment.

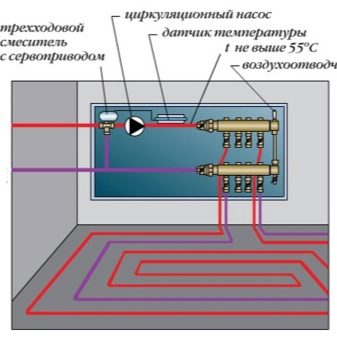

Kinds

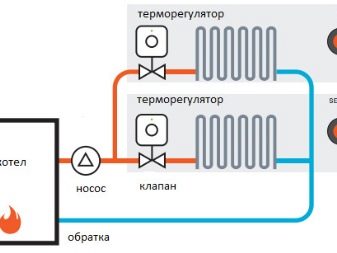

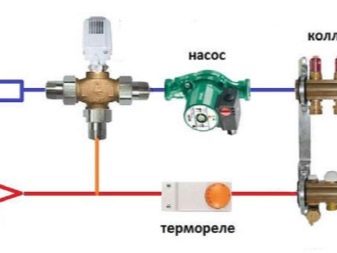

In most cases, the water supply to the warm floor is automatically regulated, and the thermostat controls compliance with the required parameters. But there are systems in which it is not provided: then boilers are used that limit the heating of water to a certain temperature. If the developers of heating equipment have not provided for such a mode, they will have to use three way valvewhich just gives commands thermostat.

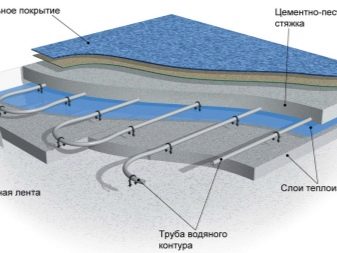

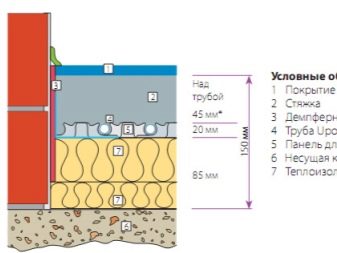

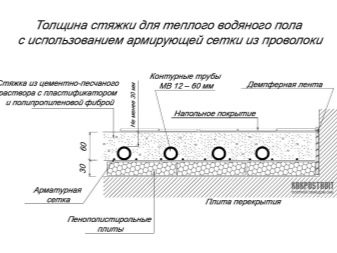

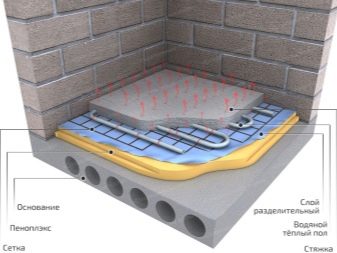

The distinction between water-heated floors is also carried out by type of performance. A concrete screed requires careful calculations that take into account thermal expansion; screed designed to keep warm in the room and does not allow him to go through the ceiling. Then use a damper tape, a grid of steel and only on top of it concrete is poured.

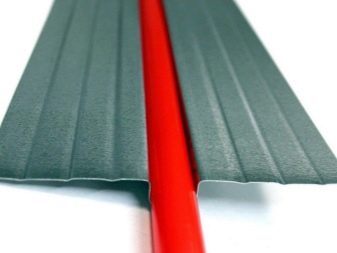

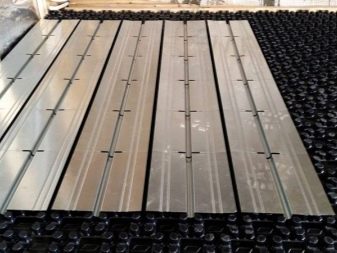

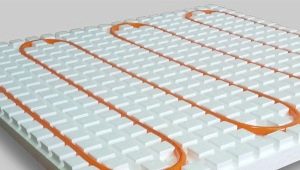

The flooring type of water floor does not require a screed; for laying the flooring, pre-aluminum plates are used, as well as cardboard or a layer of polyethylene foam. Heating of this type is advisable where the height of the premises is low, or the floors (foundations) are frankly weak. A specific feature is the need for enhanced thermal insulation, covered with polystyrene based mats. In these mats insert lamellar structures made of aluminum, which serve as a support for the individual contours of the heated floor. The face cover closes.

In many shield buildings the warm water floor is organized using wooden parts - modules or slats. The modules, or chipboard, are initially equipped with channels in which the pipes are laid. The panels are attached to the rough base with screws, the gap between which is 20 mm. Plates are not placed close together, breaks are used for laying aluminum blocks, and cardboard or polyethylene helps prevent contact between the panel and the heat conducting plate.

The pipes are mounted, then the chosen floor is put, and this is where the work ends.

The choice of a particular option is not as simple as it seems, and you need to take into account a number of features of each of them. It is unacceptable to use a concrete screed in a wooden and panel house, you will have to use a flat floor. The disadvantage of this solution is the low thermal inertia, flooring design rapidly cools. Polystyrene water floor, having a capacity of up to 0.0045 kW per 1 sq. Km.m, can effectively supplement the main heating system, but is hardly suitable as the main method of heating.

The undoubted advantage of concrete variation (where it can be used) is the ability to use all existing types of facial coatings, the technology has no limitations. However, not everyone is ready to wait 48 hours for the screed to dry. General conclusion - only by carefully analyzing the characteristics of a particular dwelling, your needs and financial capabilities, other circumstances, you can choose the right type of underfloor heating.

Always keep in mind that it is almost impossible to disassemble and reassemble the structuretherefore, it is necessary to select components very carefully, to give them more attention.

In addition to purely mechanical components, its practicality is of great practical importance when using a heated floor. Mechanical devices are considered more reliable and simple, but are becoming less common. Just because manual adjustment and the need to constantly monitor the operation of the device do not like people too much. If you often leave for a long time or just do not want toin case of sudden changes in the temperature on the street for the day or for the night in the house becomes uncomfortable, use automatic control.

It can be quite different in performance: some models collect information about the actual weather and, according to them, change the mode of operation, others are guided by the readings of air temperature sensors or floor covering. The most perfect (but also the most expensive) option is the programmable device.

With it, you can flexibly customize the work of a heated floor, and it will heat up thoroughly by the time of your daily return, all the rest of the time as much as possible saving hot water.

Principle of operation

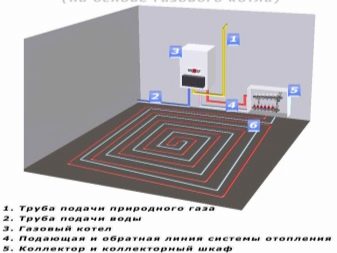

Water heated underfloor heating is considered to be quite complicated in execution, but it turns out to be simpler to use it after installation than electric one. Technically, these advantages are achieved by turning a warm liquid under the decorative layer of the floor. It can be not only water, but also ethylene glycol, and antifreeze, and some other options. The owner of the house chooses the coolant, focusing on their needs and possibilities of specific pipes. However, water is traditionally useddue to its wide availability and ease of replenishment if necessary.

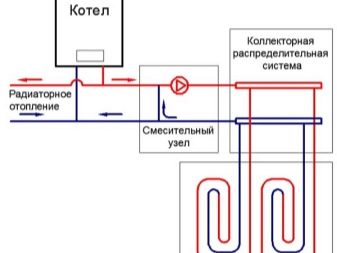

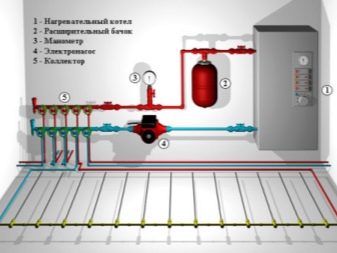

The total length of the pipes that make up the water floor is always tens of meters. Therefore, the natural circulation of the coolant is not enough for uniform and high-quality heating over the entire area. In order for the coolant to be hot enough, it is either heated using an electric boiler, or taken from the central heating system. The second option is difficult in terms of engineering, it can be very dangerous in the case of poor performance and requires numerous approvals.

In many cases, housing authorities prohibit the connection to central heating at all, and therefore install a water-heated floor can be far from all apartments.

But be that as it may, the incoming water is heated too much: ordinary room radiators are sufficiently effective only at a coolant temperature of 65 - 95 degrees. Heated floors require a significantly less heated liquid, because the outer surface of the flooring should not warm up above 30 degrees. Exceptions are made only for the bathroom and areas directly above the pipes, and the difference in these cases is 3 - 5 degrees maximum.

To do everything right, you will have to install a mixing unit, in which the just-heated water is diluted with the already passed along the contour. From this node the coolant flows back into the pipes and heats the floor surface, moving along them, already to safe values.

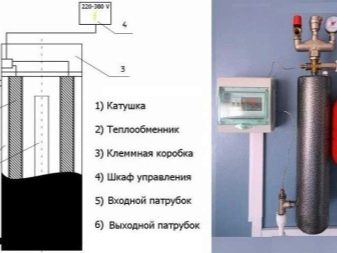

Choosing components, it is worth giving preference condensing heaters. They develop a relatively low temperature, just the one that is required for the normal operation of a heated floor. In addition to the listed devices, there are also automatic controls or meteorological sensors, means for dumping excess air from pipes and some other parts in the high-end system.

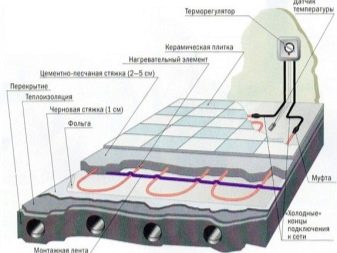

The height of the “cake” of the water floor is determined primarily by the type of tie; most of all it is when using concrete structures.

You also have to take into account the thickness of the thermal protection, how you calculate it, you already know. High-quality underfloor heating is inconceivable without a collector, and the installation height of this device is also very significant. Manifold cabinet is usually placed at floor level to minimize height differences and the associated undesirable effects. Do not install the distributor below the pipes in which it supplies water, if you can avoid it, use it.

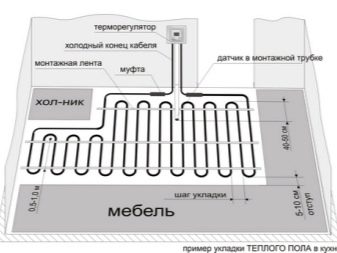

But even the best collector, established by all the rules, will not help to warm the home, if the recommended pipe installation step is not observed. It is selected primarily taking into account the diameter of the pipeline; if the coils of large pipes are brought too close together, overheating will appear, and excessive removal of thin structures will lead to the appearance of so-called thermal voids.

In an apartment building, water floor heating is almost not applicable due to the very principle of its work - since it is impossible to select hot water from heating circuits and hot water systems.

Thermoregulation

Although the temperature of the water in the warm floor is limited by the collector, it must “know” how to limit it, when to reduce, and when it is possible to increase the heating. This function takes the thermostat (in the catalogs of online stores and prospectus manufacturers for simplicity, called a thermostat). When installed, thermostats are immediately connected to devices that measure the heating of the floor covering (or air in the room) and the coolant.

The indicators that are equipped with any of the existing panels, displays information about the current heating.The microcontroller inside the thermostat constantly works with the readings of the sensors, and automatic control of the coolant temperature is organized on their basis. In simpler systems, the mechanical method of coordination is used, but still Automation is considered the most practical and convenient option.

If no one is at home, she is able to adapt herself to changes in the weather and use exactly as much water as is necessary for optimal heating. When all the inputs of the collector unit are equipped with separate thermostats, the regulator for the floor as a whole is still worth installing, since a strict temperature setting increases the comfort in the house.

If, nevertheless, a warm floor is installed in an apartment building, its temperature cannot be regulated so that radiators on all floors of the building work stably.

The output can be an autonomous heating circuit equipment that is not associated with the central heating of the dwelling. But then you have to carefully consider the consumption of gas or electricity for the boiler, find out whether it will be possible to provide the necessary flow of them through the existing communications.

Pipes

Having found out the details of how the thermoregulation of a water heated floor is organized, it’s time to deal with another point - those pipes that will deliver the heated coolant to the right places. Underfloor heating can be used in construction of metal, plastic, polyethylene, stainless steel, polypropylene and copper. Any of these types of plumbing manifests itself well both in screeds and when using flooring.

For your information: all bays must be laid without any connections, and when one of them does not allow closing a certain section, the structure is divided into a number of contours. Be sure to connect each of these circuits to a separate input comb.

When choosing polyethylene products, be sure to ensure that they have the necessary reinforcing layer.

In addition to the material, the diameter of the pipe is always taken into account: by reducing the width of the pipeline, it is possible to make its single segment shorter, but it is not recommended to use very long contours. The point is not only that it increases the cost of purchasing components, but also in the senseless accumulation of large amounts of water. If there is too much of it in the circuit, the heating becomes inert and cannot react flexibly to changes in environmental conditions.Therefore, in a typical composition of a heated floor, only pipes are not less than 1.6 and not more than 2 cm in diameter.

We must not forget about what kind of flooring will be laid on top of the heating installation. Copper systems are quite expensive and are recommended only under the floor with a large heat-saving effect. Always read the operating instructions and the accompanying documents. There it should be clearly stated that a particular pipe is designed specifically for creating warm floors.

Polypropylene is slightly worse than metal-plastic; its bending radius is at least 8 times larger than the diameter of the pipe. That is, by choosing a design with a caliber of 2 cm, it will not be possible to bring the coils together by more than 320 mm.

Cross-linked polyethylene does not have such a drawback, but it must be fixed as rigidly as possible, otherwise the assembly will straighten and will not be able to fully carry out its tasks.

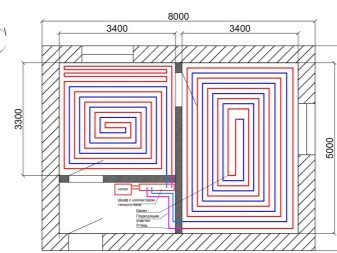

Calculation and design of the system

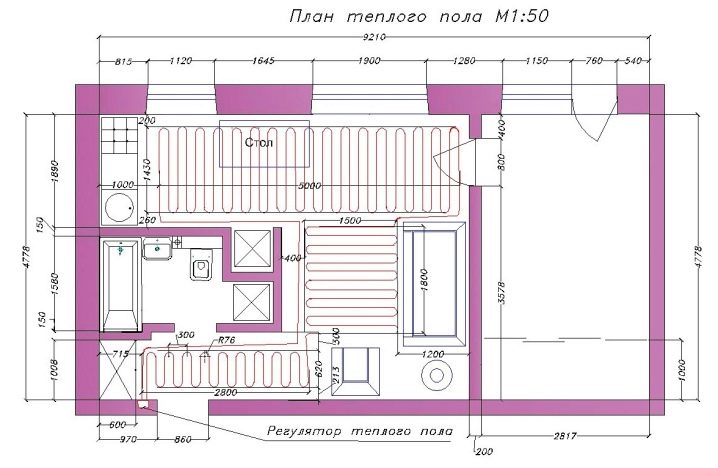

But a simple selection of material does not always give a good result, and even taking into account the properties of the finishing coating is also not enough for ultimate success. Of great importance is the accurate calculation and preparation of a competent floor heating project.Since it is unlikely that you have the necessary experience, it is better not to take risks, but to immediately turn to professionals. Collect and provide designers with information about:

- The diameter of the pipeline and the material from which it will be made;

- Peak boiler strength;

- Heat protection properties (thickness, material, number of layers);

- Total and heated area of the room;

- Materials of walls, floors, their thickness, the level of insulation, geometry.

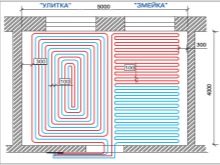

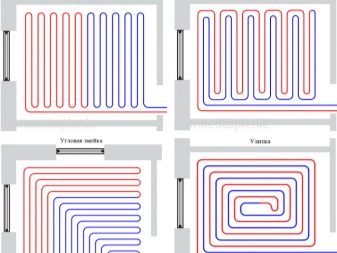

Calculate the parameters that will have a water floor, help a special computer program. In most cases, the heat loss coefficient is not less than 40 and not more than 300 W per 1 square meter. m. If the figure is closer to the maximum value, you should not save on the pipeline - bring its pipes together up to 150 mm between them, and better still reduce this distance. Another thing is if the room has thick and thoroughly warmed fences, if reliable windows are installed without a single gap. Then feel free to expand the installation step to 0.3 m, still the room will be quite comfortable and warm after the start of the heated floor in the work.

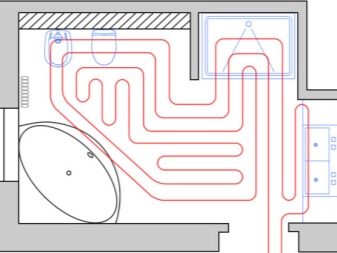

Drafting a warm floor must be preceded by a design project. Or at least consider yourself where exactly the heavy furniture, sanitary fixtures will be installed. The maximum length of continuous contours of pipelines cannot heat more than 40 square meters. m, otherwise the heat load is excessive, and no prophylaxis will help to avoid cracking of the screed or panels.

Collector selection

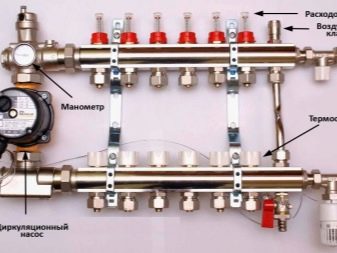

Selecting a collector, be guided by the area that will need to be heated with the help of a heat carrier, but take into account the pressure developed in the system. Most often the mixing unit is made of brass; only occasionally there is stainless steel and plastic (pre-reinforced). If you want to purchase the most reliable and stable product, specify whether the Mayevsky crane is used, whether there is a sensor that determines the amount of heat carrier passing through the device.

In addition to these, in various versions, the mixer may have thermocouples (measuring the heating of the liquid), nozzles that discharge air to the outside, and valves that change the flow rate.

The device containing the flow meter is a complete high-end equipment.But the thermostat must be installed even in the production of the cheapest possible, otherwise you face a frank marriage or even a fake. Thanks to the thermoregulation complex, the water floor heats equally well, temperature rush is prevented, which not only makes the house more comfortable, but also increases the life of the flooring.

Collectors manufactured in the last few years can be equipped with a five-point ICMA flow meter. If you want to buy a cheaper product, you should prefer products equipped with static valves. Plastic control units perform well only in small rooms, in a larger room metal structures are used.

When buying a central collector, you should choose ready-to-use kits. Carefully check if there are valves for each required outlet, both the supply and the return. It is important that you can disconnect and run the circuits autonomously from each other, and not work with the entire system at once. Note that you can attach pipes to the manifold either by using compressor fittings or by connecting nodes (a combination of a clamping ring, nuts and durable bushings).

Which boiler is suitable?

But the collector and all previous components are far from everything that will have to be taken into account. Another important element of the heating system is the boiler, without which it is impossible to ensure a steady flow of hot water. To unequivocally answer the question which heater is best, is not possible, too many parameters need to be taken into account.

So, all single-circuit devices are categorically unacceptable if you want to provide hot water, not only underfloor heating, but also a faucet. You can, of course, buy boilers, mixers of a special sample and other technological devices, but it is easier to immediately buy a dual-circuit system. Carefully calculate the power that you need, and depending on it, make a choice in favor of the suspension (up to 35) or a modification that is placed directly on the floor (up to 120 kW). The optimal version, in the opinion of both consumers and specialists, is the wall version, since the record energy in everyday life is not particularly needed.

Installing such devices is easier, and handling them is more convenient.

The undoubted advantage of the suspension scheme is the fact that the pump is installed by default in it, which means that you will not have to pick it up, spend additional funds and lose free space in the room.If there is also a boiler in the system, this is almost a miniature boiler room that can additionally supply heat carrier to radiators. Useful thing for those who do not want or can not be limited to heated floors.

As for the source of energy used in the boiler, you can choose any fuel, but its combustion must be automated. Basically, experts mount gas or electric heaters. Since electricity is steadily increasing in price, it is still more profitable to use gas, but it will be necessary to install the system that burns it in a separate room where perfect ventilation will be created. All work should be trusted only to representatives of the gas service, the project documentation is consistent with it well in advance.

Diesel vehicles are most preferable in cottages. Their installation is relatively simple, there are no special operational requirements for them. But you need to constantly monitor the condition of the boiler so that it works normally. Outside the city, solid fuel is a good alternative to all these options, burning it allows for decent power and normal efficiency.

Whatever type of boiler you choose, select a site for it, find out which additional components you have to use and which ones will be incompatible. Consider that any heater, except convection, requires the use of a collector node to lower the temperature to acceptable values.

Electric boilers with heating elements are bad in that the heating elements quickly fail; to some extent, this disadvantage pays off at a reasonable price and sophistication of technology. The electrode version has a lower thermal inertia, but it can only be used in contact with very clean water.

Attention: when the system starts up, it is required to immediately fill in the prepared liquids of a special sample or independently prepared water The advantage of induction versions is the saving of space and ease of installation of the device, even a non-professional will be able to mount it.

Solid fuel boilers are the least acceptable and should be abandoned whenever possible.

Even with a capacious bunker, where pellets can be stored in a large volume and using a heat accumulator, the cycle cannot be completely eliminated.Additional devices complicate and increase the cost of work several times, and the system starts up very slowly.

Installation

Work on installing underfloor heating does not start with the laying of insulation. First of all, you should make sure that the rough base is quite even, it should have a height difference of a maximum of 10 mm per 1 square. The selection of a material that conserves heat is determined by the initial insulation, the presence of various rooms at the bottom. It is recommended to always create a slightly thicker layer of thermal protection than follows from the calculations because it allows you to compensate for possible errors. Above apartments, offices and heated office premises of organizations, a sufficient layer of insulation is 2–3 cm.

In private houses, on the first floor of an apartment building over unheated basements, regardless of the region of the Russian Federation, you need to provide a insulation layer of at least 5 cm. And if you live in the coldest areas, take care of a heat-saving base of 0.1 - 0.15 m Thicker thermal protection is not needed, unless the house is in the Arctic.

When thermal insulation is provided, the perimeter of the room is covered with a damper tape or alternatively with a different tape thermal insulation.In its quality, strips of foam plastic, polystyrene foam and other sheet insulation are widely used. The width of the strip should be 100 mm, and the thickness should be about 10 mm, the same requirements are imposed when laying cardboard made of mineral wool. Such elements are designed to prevent the occurrence of temperature cracks at the edges of the floor covering and drastically reduce the loss of heat through the surface of the walls through the foundation.

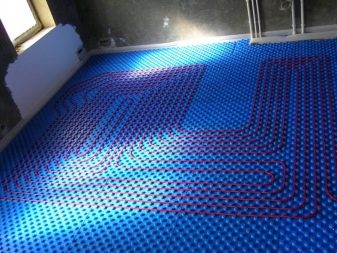

Then comes the turn of laying pipes and fixing them. Often on top of the insulating layer is placed a grid of metal with a pitch of 50 or 100 mm, which is considered the most practical. To keep the pipes firmly on the rods, they need to be fixed; for this purpose, perfect plastic collars and steel wire. If the manufacturer is concerned with applying markings to the insulating substrate, exactly according to this marking, fasteners are plugged into the base of the floor, which then will hold the inserted pipe.

It is even easier to use polystyrene plates; having fixed them, you will be able to clamp parts of the pipeline between the projections provided for this purpose.

A heated floor with a concrete base requires pouring the screed at least 30 mm above the level of the pipes.40-50 mm of concrete is poured under the tile, but if laminate is put on top, linoleum will suffice only 15-20 mm. But it will be necessary to supplement the “pie” with another reinforcing mesh so that the construction as a whole turns out to be more stable. To make a concrete screed technology allows only after starting the heating system under pressure, it is possible to use at work only cement of a category not lower than M-300.

Concrete should be dried for at least 28 days even in ideal conditions, it is unacceptable to artificially accelerate this process, because cracks may appear. Only after complete hardening it makes sense to proceed to the final finish.

Assembling a warm floor, the thermal valve is placed in a jumper, preceding the circulation pump in the diagram. This valve can be made on a two-way or three-way system; in both cases, opening it initiates mixing of the coolant, makes heating more intense.

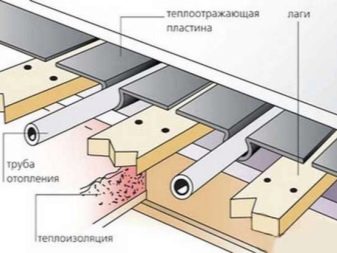

On wooden floor

Until recently, it was believed that installing a warm floor on a base of wood does not make sense at all, because the tree itself has a sufficient level of insulation. There are no speeches about the use of concrete screeds, a modification of the flooring method is applied.Pipelines are located directly on top of the lag or bottom boards in specially prepared channels; These channels collect and transfer heat further due to the presence of special plates that have recesses extended in length for pipes.

Along with the retention of parts of the pipeline, the plates increase the rigidity of the entire system, which means that there is no need to use a substrate.

It should not be forgotten that budget class solutions involve replacing the plates with aluminum foil 0.02 cm thick. When there is still a need to apply a substrate - for example, if laying ceramic tiles, linoleum is being prepared, gypsum fiber boards or DSP should be used. As thermal insulation, these materials have practically no value, their role is purely mechanical.

The difference when laying a warm floor on a wooden underlying layer is also due to the individual way of preparing the channels.

There are two of them, and every home owner should choose for himself what suits him better. So, if wooden logs are located at the bottom, you can purchase woodchip blocks, the holes in which are made by the milling method. Channel distances are determined by a strictly specified level of thermal conductivity of the entire structure.The advantage of the finished set can be considered that you will immediately have a full set of components for high-quality and fast installation.

But a serious disadvantage of the modules for the formation of the flooring is their price, which in many cases is comparable to the same volume of a natural log cabin. Wanting to save money, many use lath structures; slats are made from planed edged boards or from moisture resistant plywood. Sometimes for their manufacture the same two types of building boards are used, which were discussed above (thickness strictly from 2.1 to 2.8 cm).

The distance between the individual slats is often kept equal to the thickness of each of them, so that the pipe can fit and not suffer from changes in the size of the tree under the action of heat. As for the width of the coordinating rail, it should be equal to the design gap between the pipes.

Finally, we will talk about another relatively new, but increasingly popular, way to insulate a wooden floor. Take the edged board and on one side of it take out ¼ with the dimensions of the groove. Further, at least 70 mm from the plane of the wall, the milling method makes an unbreakable strip with the same depth (this will help to bring the pipes to the next rows).

For work, use a board that is thicker than the sample size, but exactly the width of the layout with the stacking steps. Attaching to the base (beam, lag) will provide self-tapping screws, do not create a subfloor at all. Everything seems to be simple and practical, but you will have to thoroughly examine all the supporting structures, and some of them even disassemble and reassemble. Low-warmed base floors to the bottom line are packed with bars and laid with thermal protection plates. It is covered with polyethylene by 0.2 mm, and around the perimeter on the wall should hold a 50 mm damper tape.

Most often in this case, the pipeline is laid on the system "snake", the pipe is preferably corrugated with an external size of 1.6 or 1.7 cm. Where the heating circuits will turn, it is desirable to round the edges of the rails. Grooves are laid with aluminum foil with a thickness of not less than 0.05 mm.

Some professionals believe that you need to surround these materials with the pipes themselves for greater efficiency.

Floor screed

It is necessary to pour the screed over a water-heated floor in a special order and using a mixture of ordinary cement mortar with additives that increase the passage of heat.The minimum thickness of the product is 30 mm, only it allows you to make the coating stable, quietly transferring mechanical loads. The elimination of bands of heat and cold also depends on the thickness of the layer.

All the time until the screed, after pouring, reaches the required strength, it is unacceptable to include heated floors. Therefore, it is necessary to test their work well in advance, and it is better to undertake a major overhaul of the floor during the warm season of the year, when frost and cooling are guaranteed to be excluded. The pouring process itself is recommended to follow the beacons, especially when finishing the floor covering requires an extremely smooth, neat draft part. Thermal insulation around the perimeter is always done higher than the finished floor will rise, and after the screed finally hardens, the excess is cut off with an ordinary sharp knife.

Never put aluminum foil and materials based on it into the curtain., because in less than three months, how it all becomes dust, and the heat protection will be reduced to zero.

You can use a self-leveling floor instead of a screed, but note that a polymer fill can eliminate only minor height differences.If the rough base is uneven, you will have to apply a classic mixture of cement and sand with the necessary additives. The advantage of self-leveling floors is considered to be a very small thickness (not more than 35 mm), the ability to withstand impressive mechanical loads, the lightness of the material itself and its visual diversity. As a pressure distributor, the liquid layer proved to be very good, and its thermal conductivity is much better than even a modified mortar.

But there are a few drawbacks: you will have to fill the pipes with a very large amount of the mixture (not so cheap), and in several stages.

If everything is done immediately, the coating can quickly crack.

What better to connect?

We have already dealt with boilers and collectors, now we will consider the heating elements themselves. In private homes, it is preferable to use a dry connection method when using thermal distribution plates. In practice for many years they have shown themselves to be an excellent alternative to the traditional concrete screed, but they are inferior in weight and superior in the transmission of heat, which is what the consumer needs.An important advantage is the fact that the minimum pipe installation step when using plates from 150 mm is reduced to 125 mm, which means that even in very cold areas the floor will be comfortable.

With self-installation, you will not need to deal with the fitting of reinforcing nets and attaching the pipeline to them, this is completely unnecessary procedure in this case. The big plus is that immediately after the installation of the finishing floor covering, it will be possible to immediately put the floor heating system into operation. The plates are heated very quickly, while the concrete still has a fairly large thermal inertia due to its considerable mass. Heat exchangers made of metal absorb three times less than the height of the room than even the lightest concrete screeds.

It should, however, be aware of the disadvantages of metal thermal distribution plates: they not only heat up quickly, but also lose heat even faster when the boiler is stopped. And the cost ultimately turns out to be higher than when using traditional mortar. To some extent, this difficulty is eliminated by the independent production of plates, but note that you will need to use a special machine.

Tips for choosing

A set of floor heating under the parquet and laminate should be laid on polystyrene plates, no intermediate layer between them and the finishing coating is required. If the top is a tile or linoleum, the base is created from wood-shaving or gypsum-fiber coatings. Returning to polystyrene structures, it should be emphasized its advantages in country and country houses with not too high ceilings. In the case when you want to achieve maximum environmental friendliness, you need to put a water floor on top of the modules or rails.

The width of the slab (module) should be either 13, or 18, or 28 cm. Lay in a project the thickness not less than 2.2 cm, and the interval from one plate to another - 2 cm.

Modular flooring is thicker than slatted and should be used primarily on the ground floors.

In the frame house you can put a warm floor in any way, but the pitch is limited to 150 mm, so get more pipes. The power is quite allowed to be calculated by approximate values - if the building is thoroughly insulated and the double-glazed windows are installed, it should be approximately 40 W per 1 sq. M. m. If the house is relatively old buildings and insulation is practically absent, this figure is usually 70 or 80 watts.

Very worn out and not repaired buildings have a heat loss of more than 100 watts per 1 square. m, and they need to be compensated by heating. But the situation is even worse in new cottages without wall insulation and with panoramic windows - there heat can be 0.3 kW per square meter.

It is quite possible to equip a water heated floor on the balcony, and experts recommend in that case use the system "Snake", providing the most uniform warming up. Given the intense heat loss, the gap between the pipes can not be made more than 100 mm, otherwise the coating will be cold. A slab of insulation material, on the contrary, it is desirable to use a thicker, so they safer to save precious energy.

Choosing a distributor (collector), it is necessary to give preference to the same company that produced the thermal sensor, then there will definitely not be any compatibility problems between the components. And ideally, in general, all components should be of the same brand.

As for the coolant, the underground heating system can use the same substances as the radiators. Up to one third of all warm floors are filled with antifreeze (mixtures of propylene glycol and ethylene glycol). Go to the choice of technical fluid as carefully as possible. and pay attention to the full list of its components, basic physical properties. For pumping antifreeze, the total pump capacity must be 1/10 more than when using water, and the pressure generated in the system generally increases by 60%. In this case, it is necessary to increase either the diameter of the circuits, or their total length, taking into account the reduced heat transfer from the non-freezing liquids.

An advantage when using antifreeze is that the replacement of the coolant can occur 3 to 5 times less than when pouring water into the pipes. It is possible to increase its quality by subjecting to distillation and adding softening agents.

It is absolutely unacceptable to pour automobile antifreeze into the heating circuit; only specially selected mixtures are intended for this!

Manufacturers

Among the manufacturers of warm floors, a joint Russian-Italian company Valtec It has long attracted the attention of consumers and has earned a number of favorable ratings. In the assortment of the concern are, for example, pipe category Pex-evoh with a diameter of 1.6 or 2.0 cm.To connect them, brass fittings are added to the package. The required protection against the penetration of oxygen from the outside is provided by the coating with polyvinylethylene.

Rehau - a company no less famous, deservedly associated with traditional German quality. Engineers of the company know the secret of how to make the most flexible pipes. It is possible to bend them in rather wide limits, without being afraid to damage or provoke a leak. Much attention was paid to the structure of the internal walls - now they absolutely do not accumulate pollution, which allows to reduce the requirements for the preparation of water poured into the heated floors.

Reviews

General reviews of water heated floors are rather favorable. Even those who initially believe that this is just a waste of money, having tried the advantages of such products in practice, drastically change their mind. The heat distribution properties of the underfloor heating system are rated highly, and often positive ratings are associated with the use of underfloor heating in bathrooms.

Metal pipes, judging by the reviews, are able to serve at least 10 years without a single complaint.Consider that in large rooms, where there is a minimum of furniture, often experienced people are advised to heat only the middle, so it was not too stuffy.

Also, it is not recommended to use water heated floors in toilets and kitchens, otherwise the smells typical of these rooms may increase. Better make sure that there is effective thermal insulation.

But systems with sensors and high-quality temperature controllers are always rated higher than usual, they are recognized as the most convenient and practical to use.

Successful examples and options

It is possible to apply a water heat-insulated floor practically anywhere, this method of heating has no special restrictions. Now you know exactly how to choose components for it, how to pack and connect them, how to calculate the required power. Now let's see a few of his most successful performances.

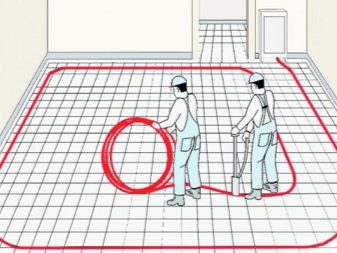

This is how the professionals work on pouring the heating system with a concrete screed (one corner away from the entrance is already filled in, the work is counterclockwise).

And then simply and gracefully installation of a heated floor in a frame house.

Excellent modern collector for supplying water to the heating system.

How to make a water-heated floor with their own hands, see the following video.