Using a warm water floor from a gas boiler in the house: the pros and cons

Independent heating in a private house is perhaps the best option, which every year becomes more and more relevant for the Russian people. The user, choosing this method of heating, becomes independent of central heating and decides when he should start using heat in his own house.

Kinds

All boilers are divided according to some criteria. Below are the main categories of separation.

By type of fuel

Gas

Differ in profitability and energy efficiency. The cost of using gas in this unit design is small compared to other energy sources, and the efficiency is high.

Electric

In use, these boilers are much easier than gas. However, the cost of the design itself is higher. Water flow is heated by electric heaters, electrodes or induction elements. Among the disadvantages of using this type of equipment is the following:

- High cost of resources expended.

- If, in addition to a warm floor, radiators will be used in the house, then it is worth noting that not all radiator systems will allow for rational use of thermal energy. In this case, the use of cast iron and steel batteries is not recommended. The best option would be to install bimetallic or aluminum radiators.

- Permanent dependence on power supply. In the event of a power failure, the user may be left without a heat source.

- For equipment with a power consumption of 9 kW requires a three-phase network of 380V. In the case of its absence, it is necessary to obtain permission, which is not always possible. This is especially true of old buildings.

Solid fuel

The work of this type of boiler is provided by solid fuel. It can be firewood, pallets, coal and other burning materials. However, some disadvantages of this category of equipment make it a less attractive source of heat than the gas heating option:

- For solid fuel boilers, it is always necessary to provide full-flue chimneys.

- This option is performed exclusively in the floor version, and large mass and dimensions force the user to search for a separate room.

- When using such equipment it is necessary to have a reserve of dry fuel.

- You must constantly put fuel into the furnace.

- Dry fuel every year only becomes more expensive.

Diesel

The work of such a unit is carried out at the expense of diesel fuel. Autonomy of independent work - up to several months. There are also disadvantages of using such a unit:

- When installing this type of equipment, the user will face the problem of finding the appropriate room. The fact is that it must meet strict requirements.

- The thickening of the fuel. This can occur if the coolant cools down to +5 degrees. To protect yourself from this fact, it is necessary to provide heat insulation of the pipeline and filters. Also, to avoid this problem, you can think of heating the system.

- Liquid fuel requires special packaging made of plastic or steel.

- Equipment must be constantly cleaned due to the continuous formation of soot.If this is not done, then fuel consumption will increase due to deposits.

- When operating a diesel installation, there is a strong noise.

Combined

Demanded version of the boiler equipment for a private house, where there are interruptions in the supply of fuel. This type of boiler has two fireboxes, allowing you to use one of the types of fuel, or one universal furnace, with which you can use different types of heating resources. The main disadvantage of such an installation is its high cost.

Split by placement

Allocate:

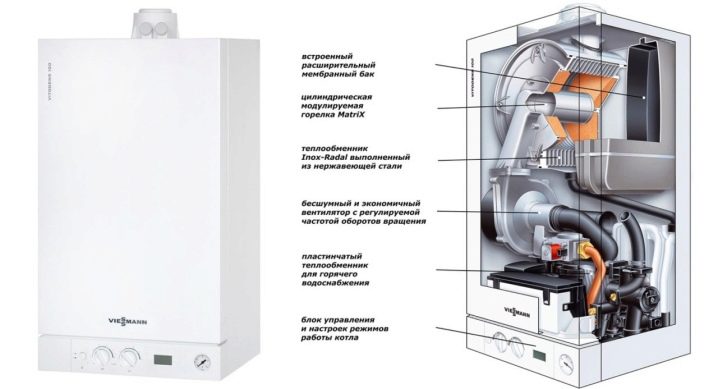

- Wall mounted. This version of the equipment is installed on the wall and requires sufficient strength from the coating. For example, walls of aerated concrete can withstand such loads. These boilers can heat small and medium areas.

- Outdoor. This type of equipment is installed solely on the floor. The boiler has a large size and is able to warm a huge area.

According to the material of the heat exchanger

Allocate:

- With copper heat exchanger. This option of heating equipment has a compact size and low weight. The inertia of the heating system in this case is small,that allows automation to instantly respond to user requests and respond to changes in temperature in the premises. This allows this unit to work in economy mode. However, such equipment requires a pump for a constant circulation process and to avoid water overheating.

- With cast iron heat exchanger. All manufacturers in the manufacture of boilers with such an element keeps secret the composition of cast iron, because it determines all the necessary best qualities. But it is worth noting that the most expensive brands of boilers with such elements are equipped with gray cast iron, because it has resistance to temperature extremes and is a plastic material. From the positive characteristics of this type of boilers, it is possible to note the high heat resistance and corrosion resistance. The disadvantages include inertia and huge size.

- With steel heat exchanger. About this category of boilers you can say the following:

- Low cost.

- Easy to repair.

- Immunity to temperature extremes.

- It has a large size.

- Inertness

- Short life

- Stainless steel. On sale it is found in condensation and diesel boilers, but not as often as it has a high price indicator. It has the following characteristics:

- Resistance to high temperatures.

- Virtually non-inert.

- Anticorrosion

- Durability.

- With a silumin heat exchanger. Boilers with such an element appeared relatively recently. It is an alloy of silumin and silicon and is used mainly in condensation units in a cast form. Its main property is opposition to the aggressive qualities of condensate, which appears in huge quantities.

Separation by combustion chamber type

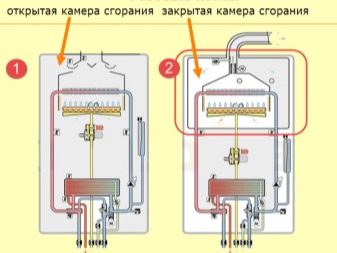

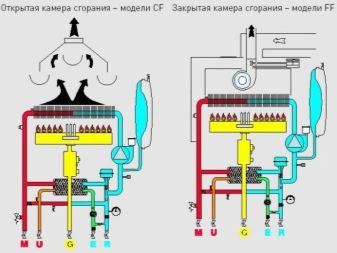

Allocate:

- With an open combustion chamber. Such heating equipment is characterized by work due to natural draft. Air intake in such a boiler takes place from the room, and the output of combustion products is carried out through the chimney.

- With a closed combustion chamber. This device uses forced traction. It appears due to the installed fan, which removes the combustion products through a coaxial pipe. Coaxial chimney is a pipe in the pipe.The outer component plays the role of tightening the air, and the internal component - the release of waste material.

Such a boiler can be used in apartments without allocating a separate room.

Boilers with a closed combustion chamber are divided into two classes:

- Turbocharged. The device has either one or two turbines, due to which the air is forced and the waste products are withdrawn. This device modulates the power of the burner and adjusts the intensity of rotation of the fans.

- Condensation This type of aggregate is based on the accumulation of thermal energy produced during the formation of condensate. They differ in economy and high performance.

The separation by the number of contours

Allocate:

- Single circuit. Such models are designed for space heating.

- Dual circuit. This type of boiler is necessary to provide the house with heat and hot water. But in such units you can find several versions of heat exchangers:

- Dual This element consists of primary and plate module. The primary module is a tube with ribs; it is responsible for heating water for the heating system; plate - a set of plates, is responsible for water for hot water supply.

- BithermicSuch an element consists of two tubes inserted into each other. The inner part performs the function of heating water for hot water, the outer one is used for heating.

Burner type separation

Allocate:

- Single stage burner. Such a device is usually installed in non-volatile wall gas boilers with a single circuit. It performs the function of maintaining the temperature of the coolant.

- Two-stage device. This device has two modes of operation: 30 and 100% power. Gas consumption in such units is reduced due to the smooth switching between operating modes. The device works non-stop. When water is heated to the required parameters, the power through automation is reduced to 30%.

- Modulation device. Power in such devices is regulated by microprocessor electronics from 10 to 100%. The intensity of the combustion process varies, depending on the parameters of the heating system.

Also, boilers are non-volatile. Separately, we note this type of boilers. Found only on gas fuel. Differ in lack of dependence on the electric power.Instead, in such boilers used mechanics that react to changes in the parameters of the coolant temperature.

Principle of operation

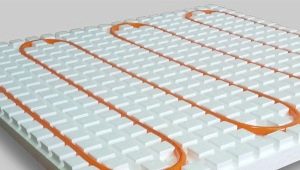

Gas equipment is both a source of hot water and a receiver of cooled coolant. The heated water stream, leaving the gas equipment, circulates through the floor heating system. Its temperature gradually decreases, giving away heat energy to the pipes.

After the traversed path, the water returns. One part of it is heated, the other is mixed with a new hot stream to obtain a consistency with the desired temperature parameters.

Safety requirements

The following are some of the safety requirements for using a gas appliance in a home:

- For some types of gas equipment it is necessary to provide a separate room.

- For a room with gas equipment, a gas analyzer device is required.

- In the boiler room should not be flammable objects.

- To place the boiler you need some free space on either side of it.

- Do not repair gas equipment independently, as well as all additional safety features.

To install a hinged gas appliance, it is necessary to provide a fire base on which it will be installed.

Connection Features

Before you trim the floor heating and gas equipment, it is necessary to alert the collector and the floor heating system itself. A warm water floor can be connected to a column or other type of gas equipment in the following ways.

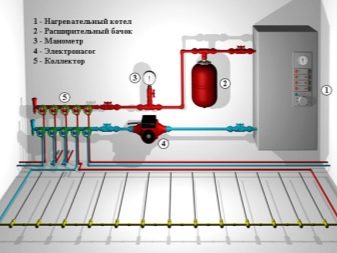

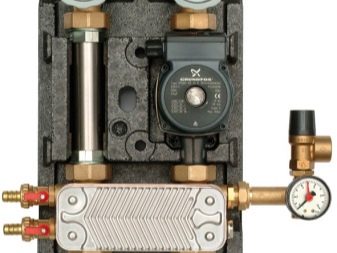

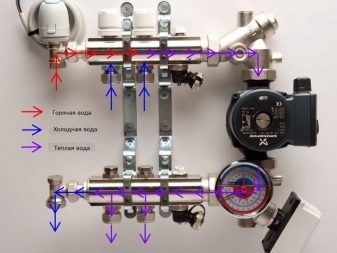

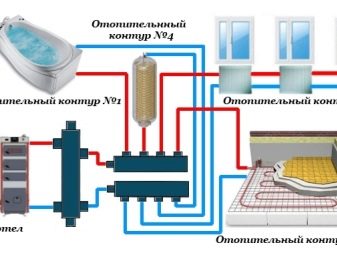

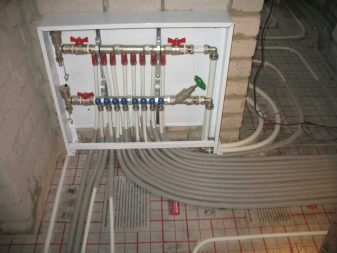

Collector option

The basis of this method is tying the boiler, distributors and pipes. The location of the collector cabinet should be convenient: you need to bring the return flow and flow. But first you must install the valves on the collectors. It can incorporate a thermometer to visualize the temperature.

It is often necessary to turn off one circuit for repair or maintenance work without stopping the system. Therefore, it is strongly recommended that when choosing a ready-made solution be based on the practicality of the purchased product.

For example, when buying a ready-made collector cabinet, it is better to give preference to brand names, which include the necessary taps at all outlets of the cabinet.

Pipelines, taps and collector systems are connected to each other using fittings, and collectors and floor piping through special connectors with clamps, bushings and nuts. If the diameters of the holes do not fit together, adapters are used. In this example, it is necessary to connect the return and flow with pipes and valves, and the collectors - with the pipes of the heated floor. This is one of the easiest ways to tie a warm floor.

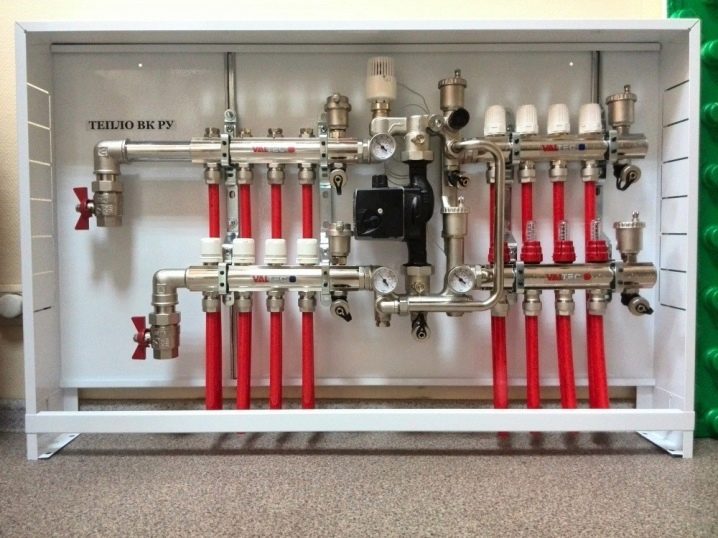

Full collector based system

In addition to valves, there are also:

- Three-way valve.

- Air vent

- Tap to drain.

- Circulation pump.

In practice, replacement of valves at the inlet and outlet to thermostatic adjustable taps is often found. By means of them it is possible to regulate throughput, thanks to the thermoballs installed in them. The three-way valve is responsible for mixing the return flow and supply, which is necessary to lower the temperature of the water circulating on the warm floor, which can be laid along wooden beams.

The mixing pump will help to organize the intake of water flow with a minimum temperature, after which it will add it to the flow.To do this, the pump must be installed between the pipeline and the supply manifold, and the third outlet connected to the return in front of the return pipeline.

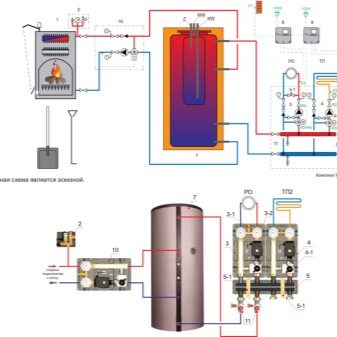

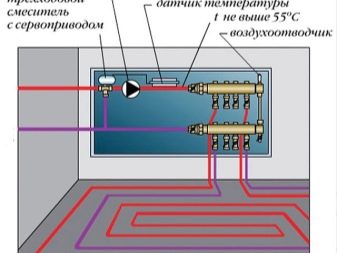

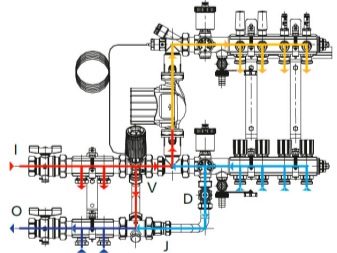

Scheme with mixing valve

In this variant of connection of the boiler and the circulation system, instead of the mixing pump, a three-way mixing valve is used. To use this scheme circulation of water flow should be good.

The installation of this element must be done at the outlet of the return pipe from the collector. The pipes from the boiler unit are connected to the collectors on the one hand, and on the other - a splitter to each of the collectors. Attach an air vent to the splitter device on top, and a drain valve is placed on the bottom.

Connection diagram using a circulating pump

Mainly used for connecting to central heating. It is installed on the return pipe so that there is more heat in the radiators. However, to reduce heat flux, the installation of such a pump is often made at the feed.

The use of a condensing boiler in a heated floor system is advantageous for cold return.

Advantages of using a gas boiler

Among the main advantages include:

- Adjustment of intensity of heating happens the user.

- At any time, the user can maintain a comfortable temperature for him.

- Fast system response to user actions.

- Saving resources and money.

- Reliability.

Disadvantages of using gas appliances

When choosing a heating system, it is worth remembering the following:

- Volatile gas boilers in the event of a failure in the supply of gas or electricity will not be able to perform their basic function. However, this circumstance can be easily replayed by installing an uninterruptible power supply at home and paying for gas on time.

- In case of installing a gas boiler, it is necessary to provide for grounding.

- The presence of a permanent source of water.

- According to the regulatory documentation, when installing some gas equipment, it is necessary to provide a three-time air exchange.

- For a number of cases, it is necessary to provide a window of specific dimensions in the room, as described in the relevant documentation governing the installation and operation of gas equipment.

- For normal operation of the gas device requires a certain height of the room.

- The whole process of gas supply to the house may take more than a year.

Tips and tricks

It is necessary to approach the choice of the heating system deliberately and unhurriedly. Below are tips from experts who will help a person understand whether he needs a heating gas system in the house and what you need to pay attention to if you choose it:

- The choice of gas equipment. In addition to work related to the arrangement of a heated floor, it is necessary to purchase gas equipment that would allow the use of a heated floor. Not all gas boilers are endowed with such a function. Therefore, when buying, you should pay attention to the availability of this functionality.

- When the gas condensing boiler is located in the basement in case of equipment failure or unauthorized shutdown, the formation of an “ice rink” is possible during the cold time of the day.

- Preference is given to brand brands of the boiler, for example, Baxi or Navien. They are adapted to the Russian climate and have a long warranty. In addition, these brands of boilers have their positive aspects, thanks to which they are currently the most popular for a country house heating system.

- After connecting, you need to test the system.This should be done without using the maximum power of the gas unit.

- In order to achieve maximum comfort in the use of a heated floor through a gas boiler, it is necessary to correctly select the floor covering.

The use of uninterruptible power supply units will protect against problems with a power failure.

A visual video about the principles of the warm floor, see below.