Features of mats for a warm water floor

The desire to live in a cozy and warm house from ancient times forced people to look for new and new technologies of construction and insulation, to invent heating and insulation systems. The modern level of comfort has reached heights, which previously could only dream of. A special comfort and atmosphere of security in the cold season create warm floors. This type of heating is very popular. The market offers a huge range of different systems and additional materials with the necessary technical characteristics and ease of installation.

Technologies for arranging such systems are such that without the involvement of specialists it is quite possible to install a warm floor in an apartment or house with its own resources.

Purpose

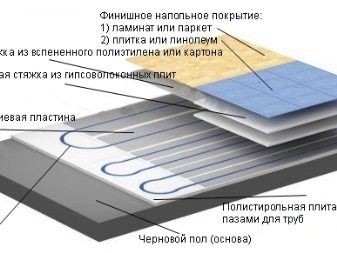

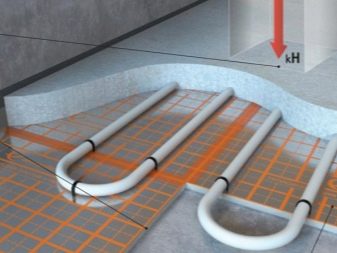

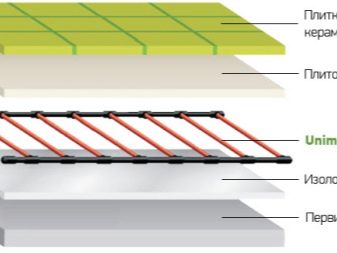

The underfloor heating system is a multi-layered “pie. "By the form of heating elements, it is divided into electric and water ones, and recently a new type has appeared on the market - infrared warm floor.In all cases, the heating element is laid on a heat insulating substrate or a special mat, the use of which makes the work of the entire system efficient and economical.

Mats perform several important functions at once:

- The special relief design and the applied marking facilitates the correct layout of the heating elements and their reliable fixation in a predetermined position.

- Many types of such mats have soundproofing properties. The noise absorption level is 23 dB for a 2 cm layer.

- Produced mats and film waterproofing layers that prevent flooding of the lower floors with leaks.

- The main function is heat insulation. Mats direct heat flux upwards, preventing significant heat loss and reducing energy costs, and consequently, finances.

- Heat reflecting function - provides the redirection of heat flux upwards to the surface of the finishing coating.

- Mats withstand significant loads, including dynamic (when residents walk on the floor), the severity of the screed and the heating circuit with hot water, the mass of the finish coating.

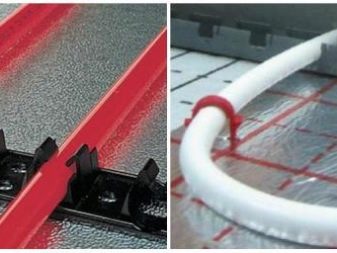

- Plates with clamps for heating pipes, special locks for quick connection of plates are produced.

Advantages and special properties of mats:

- Comply with fire safety standards, they ignite self-extinguishing when ignited.

- Absolute non-toxicity and environmental friendliness.

- Fine elasticity, keep a form during all term of operation.

- Resistance to temperature jumps when the heated floor is turned on and off (from +180 to -180 degrees).

- Chemical inertness, resistance to bacteria, rotting, oxidation.

- Do not absorb water and do not swell when immersed in it.

- Unavailability of hot items for residents, children.

- Profitability in use.

In order to withstand all these loads and to maintain a stable form, the mats must have a certain density of the material - at least 35 kg / m3.

Types and features

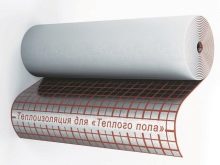

Roll foiled substrates are made of penofol (a type of foam) or polyethylene with a layer of foil and markings on one side. Cloth rolled into rolls. They are very light and easy to carry. It is also very easy to install - just roll the foil up.At the joints are glued with a special tape.

The disadvantages of this material include the need to install a special metal mesh for fixing the heating elements with clamps or clips. The rolled heat insulator is suitable for underfloor heating systems that perform the function of additional heating or creating separate comfort zones in an apartment if there is a heated room below the floor.

On the first floors and in private houses, where the ground or basement is under the floor, the foil substrate is not suitable; it will not be able to efficiently store heat in such conditions.

Foil matte plates made of mineral wool, polystyrene foam, from basalt, foamed polyethylene have a thickness of from 2-10 mm for penofola to 20-100 mm for basalt.

Heat-insulating mats with a film are made of high density polystyrene foam and are covered on one side with a foil and a layer of polymer film. The film protects the foil from the aggressive environment of the concrete screed. Marking on the film facilitates the placement of the pipeline. It is possible to mount the tubes with brackets.

Warmer and denser than foil,they are recommended for use in systems where underfloor heating performs the role of primary heating. Installation becomes easy thanks to the mounting on the lamella.

Foam plates are made of various thickness, sometimes with a thorn-groove system. If there is no such attachment, the plates are put on end-to-end glue. Thermoplastic plates have a foam structure and have high thermal insulation values. May have special grooves for pipes.

Mineral wool is also a long-standing and common heat insulator, but there is no reflective film and markings on the thick layer.

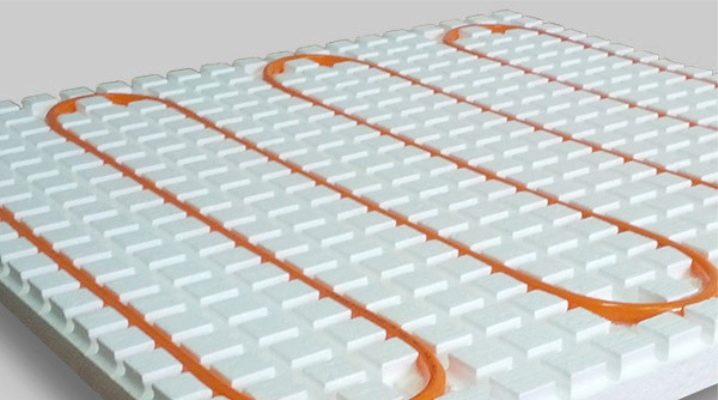

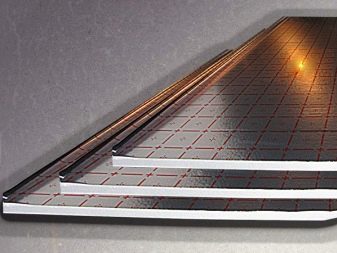

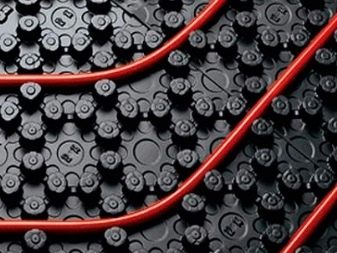

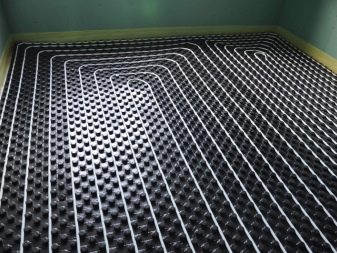

Polystyrene profile mats are equipped with special relief protrusions on the surface (so-called bosses). Lugs produced by the hydropellent punching method are arranged in rows over the entire surface. The distance between them is such that the standard tube of the heating circuit clearly lies down and locks onto the mat.

This ensures complete fixation and facilitates the placement of a standard pipeline with tubes with a diameter of 14-20 mm according to the chosen layout.

The thickness of such plates is 35 mm.Lugs come in various configurations: cubic, cylindrical, figured, and 20–25 cm high. The plates are equipped with locks, which securely fasten the sheets to each other without cracks into a single sheet. Such mats can also be laminated for better vapor barrier. Specifications:

- The density of the material - 40 kg / m3, has high strength.

- Thermal conductivity - 0, 037 - 0.052 W / mx K, provides reliable thermal insulation.

- Noise absorption - 23 dB at 20 mm thickness.

- The size of the mats is 0.8 x 0, 6 m or 1x1 m.

The cost of this type of insulation is higher than smooth mats, but ease of operation, technical and operational indicators make them popular components for underfloor heating.

How to choose?

When choosing mats, it is necessary to make sure of the authenticity of the presented material, since the market is saturated with various fakes, and with strict requirements for the properties and functions of heat insulators, an error in this matter will be very expensive. To avoid such problems, need to check the availability of documents for the goods, certificates of conformity and warranty cards.

If the buyer is faced with a choice of plates without a laminating layer and with it, then, of course, it is preferable to give preference to laminated sheets.The thickness of the heat-insulating plates takes into account the thickness of the screed layer and the decorative coating.

In some rooms there is already heat insulation, then you need to take the material thinner. In warm rooms, it is possible to use mats without heat-insulating properties, but supplied with lugs for precise fixing of the heating circuit.

Advantages and disadvantages

Differences in the design of various heat-insulating materials determine various factors - features of buildings and premises, diameter of pipes.

Rolled material, for example, is not recommended for use at basement levels, floors on the ground in private homes, as its coefficient of thermal conductivity is quite high. They also have low waterproofing properties.

Sheet thick plates and foiled blocks of polystyrene foam are excellent waterproofing materials and provide maximum values of heat transfer to the surface of the finishing coating.

Profile polystyrene mats of high density can withstand all the necessary loads with a margin of safety. Warm plates lead in the arrangement of underfloor heating as the main heater. Rolled sheets are suitable for use for additional heating.

Manufacturers review and reviews

The company is deservedly considered the flagship in the field of energy-saving materials. Knauf. Engineers of this brand create unique in their properties and characteristics of mats for underfloor heating. Widely used in construction and are very popular "Knauf Therm" mats of expanded polystyrene, they are high quality and affordable. This material has the following advantages:

- Relief structure with special bosses with a reverse slope clearly captures the heating tubes.

- The manufacturer guarantees tight, without gaps, the fixation of cloths among themselves with the help of locks around the perimeter of the plates.

- Mats have markup for cutting the fabric on both sides.

- The company establishes a warranty period for its products in 100 years.

- The thermal conductivity of the material - up to 0, 038 W / mK.

German company Rexay - it is a recognized leader, producing reliable components for underfloor heating of all kinds.

Oventrop specializes in a variety of designs and lightweight designs. Swedish, as well as Finnish companies produce products of high frost resistance, which is popular in the northern regions of Russia.

The recognized leader among domestic producers is the company Energoflex. It is famous for its affordable prices and a huge range of products for construction and, in particular, components for floor heating systems. Of the new models of thermal insulation mats, aluminum-coated plates with protection from a thin polymer film are very popular. This material is resistant to the aggressive alkaline environment of cement, lime or gypsum. Also produced mats with relief of various shapes.

Reviews of experienced craftsmen and nonprofessionals agree that the use of heat-insulating mats is necessary when installing any floor heating systems. Buyers note that with their use you can not turn on the heating, if there is no frost, a very pleasant feeling of comfort and security appears in the house.

Excellent reviews get warm floors and for their efficiency. Installing them costs a lot of money, but subsequent operation reduces heating costs. This is a worthy replacement for fan heaters and heaters that have been used before.

Where can I apply?

In the bathroom warm floor mounted quite often. Thanks to him, the humidity decreases and the microclimate improves, and it is just pleasant to walk barefoot.The ideal option for such installation would be a mat with bosses, a water floor. In the case of using ready-made single-core mats, you can immediately proceed to laying ceramic granite tiles, which will serve as an excellent conductor of heat. Financial affordability and ease of connection make this technology very popular for the bathroom.

In a private house, where the draft screed goes along the ground, and the heated floor is the main heating system, it will be right to choose a water floor. As a heat insulator fit thick dense laminated plates with a relief, so that they are not eaten by concrete. In this case, the heating will be sufficient, and the heat loss will be low.

Piling

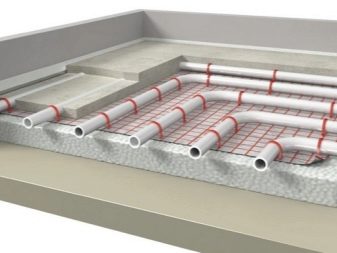

There are several ways to lay the heating circuit. The length of the pipeline is usually from 60 to 70 meters. One end of the tube attached to the supply manifold, the other to the return. The whole circuit is laid using a single piece of pipe, it can be cut only before connecting to the return manifold. Also, the electrical cable can not be shortened or cut, otherwise its design resistance and power will be broken.It is impossible to connect such a system directly - the floor will simply burn.

With the parallel method, the pipes are positioned so that they form a snake, simultaneously laying and bending them 180 degrees. With this method, the highest temperature will be observed at the beginning of the pipes, so they should be mounted, starting from external walls or windows.

The spiral method involves the installation of the circuit in the form of a double helix, the turns of which run parallel to each other. The feed part is laid parallel to the return to compensate for the cooling of the neighboring turns of the spiral. This is the best solution for large areas.

Pipeline installation methods:

- Reinforcing mesh spread on the heat insulator and fasten with flexible wire. To prevent deformations during operation, it is necessary to make a small gap between the tube and the reinforcement mesh.

- Fasteners with clamps, clips and clips, brackets, plastic harpoons to the plate insulator. This method requires special markup.

- The distance between parallel tubes should be 30 cm, and near the outer walls, windows and doors the laying step is 15 cm, the distance to the nearest wall is at least 7 cm.

What's better?

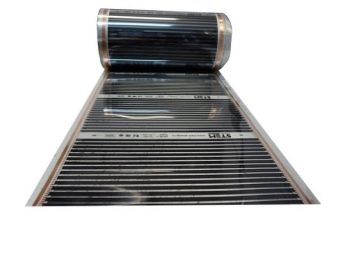

They produce mats not only for water floors, but also for electric, infrared carbon (so-called Unimat).

If the system of heated floors plays the role of not the main, but additional heating, is purchased for use in certain areas in the apartment, house, or underfloor heating only adds additional heating to the bathroom or kitchen, then ready-made electromatics are a possible solution.

Heating cable mats are single and double. Single cores have lower power, lower cost. Advantages of mats:

- The main advantage of electromatics is that the largest and most difficult part of the installation work is done by the manufacturer. The cable is already placed on a substrate or mesh of fiberglass or other polymer according to the markup. You just need to lay a mat on the floor surface and glue it to prevent displacement. The adhesive composition protected by a film is applied on many types of mats.

- Heating mats can be mounted directly under the topcoat or under tile adhesive. In this case, the thickness and weight of the so-called cake is significantly reduced compared with other types of underfloor heating.

- The use of non-combustible materials, multilayer insulation.

- The time to heat the floor to a comfortable temperature is only 10-15 minutes.

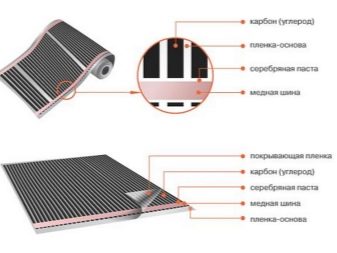

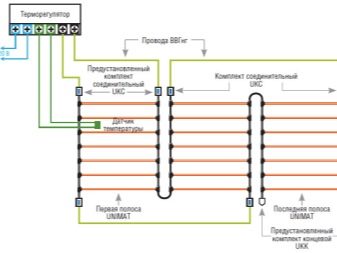

Unimat is the most innovative technology in the field of floor heating systems. It consists of parallel elements, flexible rods of carbon, silver and graphite, assembled into a single circuit using connecting wires, form a carbon rod core that heats the room with waves of infrared radiation. Such radiation heats objects, which, in turn, give off heat to the room air.

Advantages:

- Temperature self-regulation. If it reaches a certain value, carbon rods begin to emit less heat and the temperature decreases. This reduces the risk of overheating of the system, although a purchased thermostat will allow you to control the power consumption and provide budget savings.

- Infrared radiation is considered beneficial to health, ionizes the air and eliminates odors.

- It is possible to lay the finish coating immediately on the mat, it is compatible with tile adhesive, and the thickness of the tile and glue should be at least 2 cm.

The disadvantages of this material include its high cost compared to film infrared floors, the relative complexity of connection and installation.

The rod floor is sold in rolls from 1 to 7 m long, there are options of 25 m each. To save energy, it is necessary to put an effective heat insulator under the core system.

In the next video you will find a video tutorial on laying pipes for water heating on mats.