Features of warm water floors in a private house

Very popular among homeowners are outdoor floor heating systems. The best solution for creating heat in a private house can be the installation of a water floor. However, to make the right choice and install it indoors is a difficult task, since this process has its own nuances and requires some knowledge.

Features: pros and cons

Water floor heating is a construction of a heating circuit consisting of pipes. They connect to the main heating system.

The undoubted advantages of such a device are:

- The rationality of the use of energy, which avoids a significant waste of material resources. When installing such a system, cash costs for electricity are almost halved.

- Creating coziness and comfort in the home.

- Uniform distribution of heat throughout the room.

- A sufficiently high level of security due to the fact that the coolant is located under the floor, so there is no risk of getting a burn or injury.

- Undeniable compatibility with finishing materials. For example, the device is easily suitable for coatings such as tile, linoleum or laminate. If materials with chemical additives are used, this should be indicated on the packaging. It should be checked whether the manufacturer permits to install such products in residential premises.

- Connection variability. So, you can connect directly to the main heating system, or you can create a separate heat supply design.

However, the warm water floor system has some drawbacks:

- To obtain a low heating temperature, you need to have a mixer that works in conjunction with a water pump.

- Often leads to lower pressure in central heating.

- It takes a lot of time to install because of the need to create a multilayer installation.

- In case of leakage, it is necessary to open the entire coating, which leads to its possible damage.

- Warm water floor can not cope with the heating of the entire room, so there must be a boiler for heating the entire space.

In general, this design has more advantages and will certainly become a savior in the winter season. It is not recommended to turn off the system in winter.

Wiring diagrams

According to the quality of the material, the following types of laying a warm water floor in a country cottage at the cottage are distinguished:

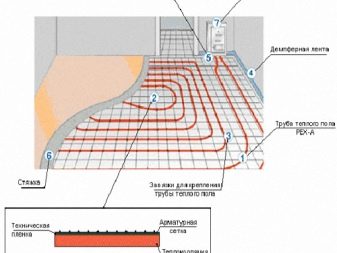

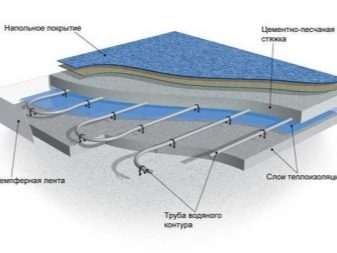

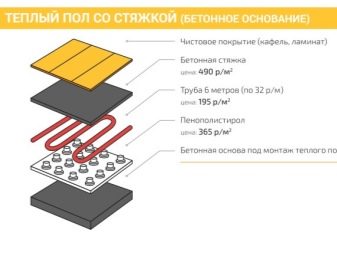

- Concrete. It uses a coupler with mounting waterproofing and heat insulation, fixing pipes with reinforcing mesh. Tile, stone or parquet flooring is used as a fastening.

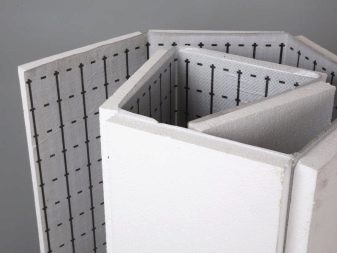

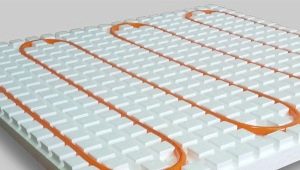

- Polystyrene. This is a simple installation option with the help of special polystyrene plates, which, after pressing, get a convex shape. Inside the pipe are placed.

- Wooden floors.

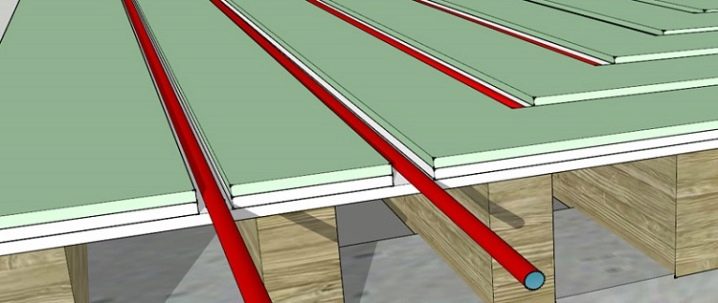

For the latter, the wiring diagram is quite simple. For the device of such a method of heating in private wooden houses there are several methods of laying water structure on a wooden surface.Plastic pipes are installed under the floor. They provide hot water.

The maximum temperature of heating of such surfaces is no more than 30 degrees, otherwise the drying of the wooden coating will begin.

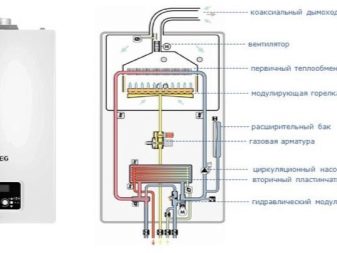

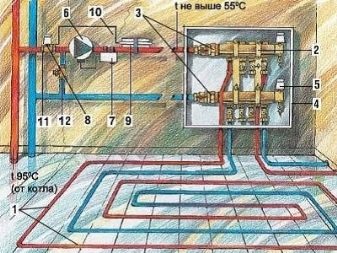

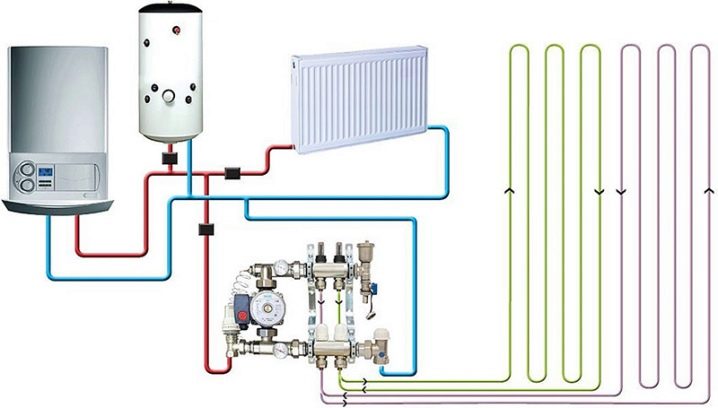

Circulation of hot water occurs constantly. It is important to remember that the heating system in the room is not associated with floor heating. The heating process is carried out by boilers of any kind. The best option would be if the boiler consists of two heating circuits. That is, one of them is designed to create heat in the premises itself, and the other for a floor heating system.

This design will save money, as the air begins to rise from the bottom up, and the convectors create heat during the arrival of cold from the windows. The system of water heated floor, which is based on a gas boiler, is the following:

- Pipe natural gas intake.

- Pipe for water supply.

- The supply line of the heating system in two directions.

- Collector.

- Two directions for a water heated floor.

Arrangement technology

Installation of the heating system is possible only after the necessary preparation of the foundation.This is done to create the perfect overlap by restoring or replacing it. This stage includes the important points:

- Remove the old coating and dismantle the rough base.

- Removal of all types of insulation.

- Cleaning the surface from contamination.

- Inspection of structures for stability by inspection. If worn parts of the beams are found, they should be cut out and replaced with a piece of the same size.

- Use of substances to protect against mold and mildew.

It is important to pay attention to the evenness of the base, the presence of protrusions. Do not allow too large drops. If the surface defects are greater than 2 cm, then it is necessary to make an alignment by pouring fine gravel. This method is suitable for laying a warm water floor under hardwood floors.

Installation of a light water floor can be made both with a coupler, and by means of a dry floor under a tile or a tree. It is important to know that it is better to start installing floors in the room where the boiler is located. One section for installation should not have an area of more than 40 m. The pipes for installation have the ability to deform, so it is not difficult to give the heating elements any shape. Experts believe that the most effective way of laying spiral.

Both plastic and metal-plastic pipes can be used. Often, experts use polypropylene devices, characterized by stability, tightness.

It is important that these structures are suitable for installation in heating systems. Otherwise, the use of unsuitable devices can lead to an inefficient heating scheme. It is important to examine the markings on the pipe.

As for the boiler, there is a choice. You can buy not only gas, but electric or working on solid fuel. It all depends on the location of the house. The need for a collector system is explained by the fact that it is important for ensuring the operation of the entire water floor and maintaining the desired temperature.

Not all boilers have an integrated circulation pump. In such cases, you need to purchase it separately., because without it the circulation of water is impossible. It is better to choose a pump that has three speeds. The remaining parts for the arrangement of the warm water floor system are acquired on the basis of the individual characteristics of each device.

How to make heating your own hands?

If you have to work on installing the structure yourself, then it is important to observe the following steps.

Surface preparation by leveling it

This can be done with a concrete screed or special compositions that are sold in hardware stores. Further, it is recommended to treat the base with a primer. Do not forget about the insulation, which must be laid on the prepared surface.

Laying insulation

This process is not difficult, it is enough just to fix the joints with the installation tape. From materials for insulation there are such as foam plastic foam insulation. The best thickness is 5 cm. In some cases, when laying on the ground or with increased protection from the cold, thickness up to 10 cm is allowed.

To maintain heat, it is recommended to put a metal film heat reflector on top.. This may be penofol, foam element or aluminum foil.

Pipe laying

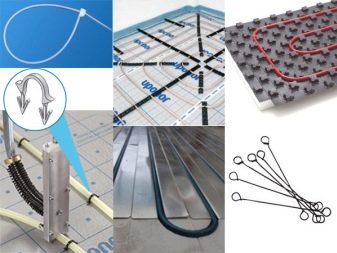

On the basis of laid out reinforcing mesh, providing full bond. The pipes themselves can be installed in the shape of a snake or spiral.It all depends on the personal wishes of the owner of the room, but the masters believe that the spiral mounting scheme is preferable. At the first variant of laying uneven heating of the floor is possible. To calculate the width of the installation takes into account the set of values. These include wall thickness, pipe diameter and other factors. The optimal length of the pipe is 100 m, as the water cools, moving away from the start of circulation.

Heating materials can be most common water pipes, but their lifespan will be much less special devices. There are subtleties of sealing pipes, which consist in the fact that the connection between them must be carried out using adapters. In case metal-plastic pipes are installed, the metal surface should be removed within 3 cm from the beginning of the pipe.

The pipe is attached to the insulation with fasteners. They are necessary to facilitate the installation of the floor and guarantee the correct placement of the pipe. Fasteners can be plastic or metal parts.

It is important to know that for a warm floor you need to use only a single piece of pipe.In this case, the maximum length of each circuit should reach 100 m. Otherwise, it will be necessary to use too high pressure for optimal heat transfer rate.

Preparation and connection of the collector

Installation of this device is carried out according to the instructions indicated on the packaging. In each case, the installation process will be different due to the fact that now there are many different models on sale. The correct location of the collector box should ensure the same water pressure in all circuits.

Boiler installation

Often during the connection of the boiler to the underfloor heating system there is a problem that the water temperature is several times higher than the water floor required for the operation. Therefore, it is important to make sure that water with lower temperature enters the pipes. This is possible by diluting the water is already cooled, which flows in the opposite direction.

The heating design must go through an assembly process consisting of the following scheme:

- Installation of control valve.

- Fastening the circulation pump.

- Installation of the collector.

- Ensuring the entry of low temperature water.

- Connect the pipe to the boiler.

If a screed is used, the process takes place under pressure. Mixtures for screed can be cement-sand, concrete or dry.

When using cement and sand, it is best to purchase ready-made products, which include special plasticizer. This element allows the solution to be plasticized., and also raises level of heating due to heat conductivity. For the concrete composition, it is recommended to purchase cement of a special brand M-300.

Dry materials include sand, various additions to expand heat and to reduce air bubbles. During the last stage of work, it is necessary to take measures to prevent cracks in time. There are two options here:

- When the room is divided into two halves, each of them is poured separately using a special tape. Further, all existing gaps are removed by spackling.

- After the screed has dried, the perimeter of the room is cut by sectors using a grinder, and the seams are sealed with silicone. Then they must be plastered.

In the construction of a wooden floor, the whole process is much simpler, since it does not require installation of a screed.It is enough to cover the boards with a special box where the heating pipes are placed. An important feature is the correct placement of pipes.. The whole structure is located at the level below the boiler. This will promote free heating and cycling over plastic heating elements.

It is worthwhile to dwell in greater detail on the consideration of the question of laying a water-heated floor without a screed. There are many advantages here, one of which is the small weight of the structure, as well as the absence of the need to wait for the cement to dry. This is the heating system that saves money.. The installation of such a construction requires the use of a base where the contours of the pipes will be laid. It can be wooden or polystyrene.

There should also be strips of metal that evenly distribute heat. You can equip underfloor heating as a tile, and under the laminate, but in all cases you need to take care of good heat transfer.

Today, an installation system using gypsum sheets is used. They are laid as a base, fill the gaps between the contours of the pipes,serve as the top layer under the selected coating. This design is easily disassembled, if necessary repair. In addition, gypsum sheets excellent heat.

Another possible option to create a water floor without a screed is the use of sheets of aluminum, which already have sections for laying the contour of pipes. But the masters say that gypsum-fiber elements are much better in quality. The advantages of such materials are as follows:

- Availability of price.

- Simple processing scheme.

- Security.

The opportunity to install warm water floors with your own hands should not be abandoned, as this system will greatly facilitate life by creating comfortable living conditions and saving money on the purchase of energy.

Competently installed heat in the home can be done without expensive specialist services. It is enough to know the necessary details of this process and choose the right equipment for heating.

Reviews

In general, reviews about the use of a warm water floor in the house are positive for people. When choosing pipes for installation of the system, consumers recommend using half-propylene versions, since they are more durable.

So, many note the convenience of a water floor in homes where children live.Most of the time the child spends on the floor, working with toys. You do not have to fear for the health of fidget, because the heat is always evenly distributed over the coating.

Examples of interesting solutions

- The option of laying a warm water floor with a snake is appropriate in a room with divided functional areas. It is assumed that there will be the use of different temperature regimes.

- The spiral type of placement of pipes assumes uniform heating of all room. For this installation, less pipe is spent.

- Using a combination of snake and spiral in the installation is suitable for rooms with external walls. For faster heating circuits are located loops, or at an angle of 90 degrees.

- The device is lightweight warm water floor allows you to use it immediately after installation.

Proper installation of the heat-insulating layer is guaranteed to preserve thermal performance during prolonged use. When choosing a metal substrate, it is necessary to distribute it over the entire surface that will be subjected to heating. This is necessary to preserve the integrity of the structure, to ensure the strength and reliability of the coating.

From this video you will learn five basic rules for installing a warm water floor.