Subtleties of the choice of pipes for underfloor heating

Currently, warm floors are very popular. The demand for such systems is explained by the fact that they are very effective in providing heating for any area. In addition, they can be combined with different finishing materials, and the installation of many heating structures can be done on their own. In order for the system to operate smoothly and efficiently, it is necessary to take seriously the choice of pipes. We will talk about this today.

Special features

High-quality and practical floors, heating the room, today are quite common. They can be used in a variety of conditions. It can be not only a private house, but also an ordinary city apartment.Moreover, people often install such heating systems on balconies and loggias, turning them into full-fledged living rooms.

The quality of operation of these structures depends largely on the correct choice of pipes. In addition, these details also affect the service life of the underfloor heating. That is why it is necessary to select suitable pipes responsibly, otherwise the construction will not last very long and will not work at full strength.

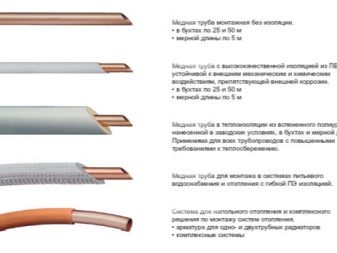

Modern manufacturers offer customers a choice of copper, steel, metal-plastic, polypropylene and polyethylene pipes. In the installation of a heated floor can not use products made of ferrous metal. This is explained by the fact that these elements are suture and it is not recommended to stack them under the tie.

Also, experts do not recommend to use steel pipes for laying a warm water floor. These elements are susceptible to corrosion, so a limestone deposit can form quite soon in their inside. The appearance of such defects may lead to leakage or decrease in throughput of the entire system as a whole.

Versatile are copper options.Their main advantage is long service life. However, it is worth considering that a water-heated floor with such pipes will cost the buyer a tidy sum. This is due to the fact that in addition to the tubes themselves, the owners will have to buy special connecting elements, fittings and reliable fasteners. These components increase the cost of the floor by about 30%.

Alternative are metal pipes for underfloor heating. The main features of these parts are their low weight and environmental friendliness. Metal-plastic components consist of several layers, the quality of which must be ideal, otherwise the pipes will leak. These items are cheaper than copper, so they are often chosen by modern consumers. Of course, their popularity is also influenced by a number of positive qualities, which we will talk about later.

Polypropylene pipes are distinguished by a large bend radius. That is why their installation is considered more complex. These types of handsets are less frequently used by customers, although they are inexpensive. Not every home master can cope with the installation of these parts.As a rule, specialists are hired for this, which leads to additional expenses.

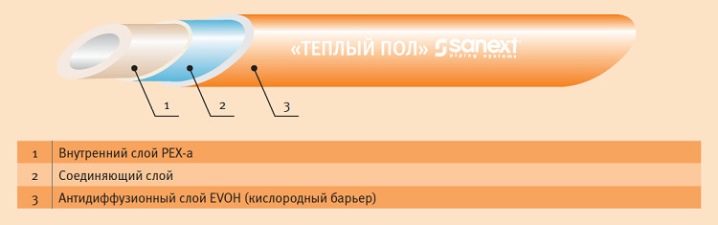

Unique properties can boast pipes made of cross-linked polyethylene. Their feature is the additional processing that they undergo in the process of their manufacture. This process takes place under high pressure, due to which new molecular bonds of the raw materials appear, and it becomes more durable and reliable.

Good heat transfer characteristic of stainless steel pipes. Such a corrugated tube is durable. According to the manufacturers, these components are not limited in service life. This feature of stainless steel pipes is very attractive in the selection of suitable components of a heated floor, but these elements are expensive, and the rubber seals in them are not as durable. They serve no more than 30 years.

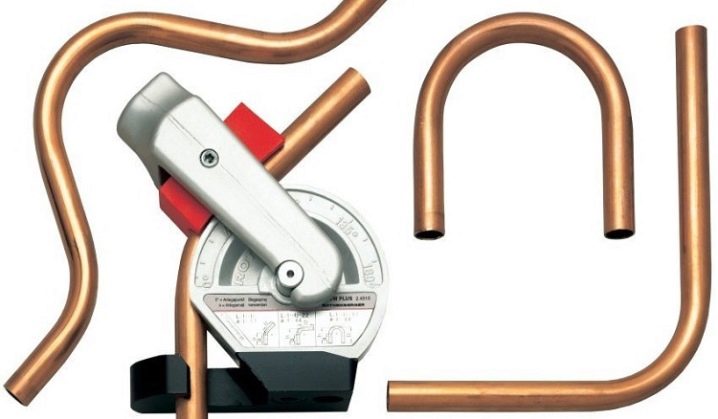

The main feature that pipes for underfloor heating must have is their elasticity. At the time of bending, these parts should not be subjected to deformation or breakage, because during the installation process, contours with a length of 60-120 m will be laid, and small bends in them will occur many times.

Kinds

After reviewing some of the features of different pipes designed for water-heated floors, you can proceed to get acquainted with their pros and cons. Knowing the detailed information about these elements, the selection of a suitable variant will be significantly simplified and will not take much time.

Polyethylene

One of the most common are pipes in the production of which cross-linked or heat-resistant polyethylene is used.

This raw material has its own designations:

- PE-X is a crosslinked material.

- PE-RT is a heat resistant material.

- Also, there are polyethylene tubes of low pressure material (HDPE).

Surely many people know that polyethylene itself is a sufficiently plastic material that absolutely does not hold the shape. In this state, it is not suitable for equipping heated floor structures. To solve this problem, experts have developed a special way of "stitching", during which the molecules of polyethylene are connected to each other. This process has a beneficial effect on the strength and rigidity of the raw materials. The quality of the finished material can be determined by its matching.

There are several types of cross-linked polyethylene:

- PE-XA (70%) - in such raw materials for the connection of molecules high pressure is used, under the conditions of which (in the presence of peroxides) they are combined with each other.

- PE-Xb (65%) - this method of stitching occurs under the action of chemicals. Most often used for this silane.

- PE-Xc (60%) is a special method of electron irradiation. Under its influence is the formation of bonds between the molecules in the composition of polyethylene.

- PE-Xd - this technology is considered obsolete. It involves the use of special nitrogenous substances.

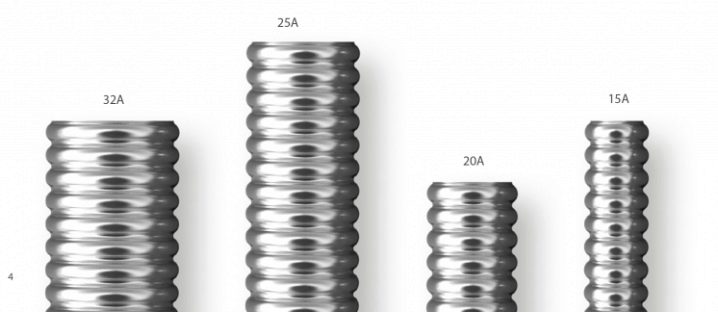

Polyethylene pipes are a good option for a floor heating device. They can boast of good thermal conductivity, excellent mechanical characteristics, as well as a minimum coefficient of roughness, which makes the resistance to movement of the coolant flow minimal. The diameter of such pipes, as a rule, is 16-32 mm.

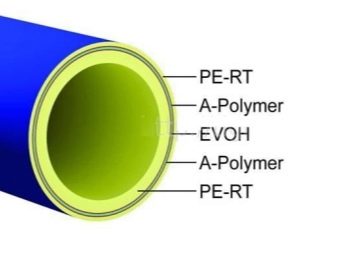

Such a pipe for underfloor heating must necessarily have an acid-proof protection in the form of an additional layer of EVOH, which is a thin film. With this treatment, polyethylene pipes will serve for a very long time, like the entire heating system as a whole.

It is worth noting that simple polyethylene pipes conduct heat a little worse than the popular metal-plastic options. Another disadvantage of these parts is their excessive elasticity. This characteristic leads to the fact that by itself the tube bends easily, but it must be firmly tied to the frame structure. Otherwise, it will take its original form. Because of this nuance of installation, polyethylene pipes complicate the process of installing a heated floor.

Relatively recently, a special heat-resistant polyethylene, which is produced in another way, has appeared. For its production, chemical reactions are used, the result of which is the intertwining of the chains of molecules, and this happens mechanically, and not by way of bonding between atoms.

Heat-resistant polyethylene is less common and common material, as long as it is considered new. It has good quality and performance, however, it is not recommended to use it for underfloor heating. This is due to the fact that heat-resistant polyethylene can reduce the service life of the heating system and degrade its performance under hightemperature

Polypropylene

Polypropylene pipes are issued in the form of small pieces. Their diameter is most often 20 mm. The disadvantage of these parts is their rigid structure, due to which they are not easily bendable, which can not be avoided in the process of installing underfloor heating.

Due to the fact that these parts are very badly bent, parts of the pipeline will have to be connected to each other using couplings using welding.

This causes several problems at once:

- Leakage sources may appear over time at connecting sites.

- The time spent on installation will increase significantly.

Before pouring the screed, it is necessary to ensure the quality of all welds of pipes. To do this, start the system and let it work under conditions of high pressure and operating temperature. Take your time checking the design work. During the operation of the floor you need to carefully inspect all connections. If water does not infiltrate through them, then the system can be considered sufficiently reliable and durable.

Of course, experts recommend using only high-quality pipes manufactured by reputable companies.Such parts are more reliable and durable.

The advantages of polypropylene pipes include:

- Low cost;

- Good thermal conductivity characteristics, similar to plastic products;

- Harmlessness (these elements are chemically neutral);

- Durability.

Copper

One of the best and quality are pipes made of copper. They are great for water heating systems.

These parts have a number of positive qualities that make them popular and popular with modern buyers:

- First of all, it is necessary to note the increased wear resistance of copper elements. They are not destroyed by the action of aggressive components.

- Copper pipes have excellent thermal conductivity. In this regard, they are ahead of polymeric materials.

- They are quite flexible. Most often, a special annealed pipeline is used in heating systems.

- Copper parts can boast a long service life. They can serve for decades without giving their owners any trouble.

- Such pipes have a large number of temperature regimes in the course of their operation.

- The inner walls of copper pipes are absolutely smooth, so these elements have excellent hydraulic properties.

Copper pipes are rightly recognized as the most reliable, durable and practical. However, they have their own weaknesses. For example, the disadvantages of such products include their high cost. Not every consumer agrees to pay large sums of money for copper pipes.

It is also worth mentioning that their installation requires special equipment. That is why the installation of copper tubes can be an impossible task for a home wizard.

Metal plastic

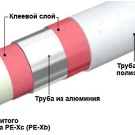

Pipes in the production of which metal-plastic is used are by far the most popular. Such details perfectly are suitable for heat-insulated floors. Metal pipes consist of two polymer layers, supplemented with an aluminum interlayer.

The popularity of these parts is due to the affordable cost and other positive qualities:

- These pipes differ in quite good heat conductivity. This effect is achieved through an interlayer of aluminum.

- Metal constructions are perfectly protected from various external damages,as they have polymer layers.

- The installation of these pipes is not difficult, since they are quite easily bent. Due to this characteristic, it is very convenient to use such constructions in the system of underfloor heating.

- You can not be afraid of damage to the screed or wear of the line, as metal-plastic pipes have a low coefficient of foundry expansion.

Pipes from metal-plastic in many characteristics are superior to ordinary plastic and even copper versions. However, when using poor-quality adhesive composition, these elements can serve less and lose many of their positive qualities.

Corrugated

Relatively recently, stainless steel corrugated tubes appeared on the market. Such specimens are considered ideal for installing underfloor heating, because they are characterized by increased flexibility, reliability, durability, and fairly simple installation. In addition, the corrugated pipe is inexpensive and is available in bays of impressive length. Stainless steel corrugation is frost-resistant and seamlessly transfers hydraulic shocks. In addition, it has a small coefficient of expansion and high thermal conductivity.

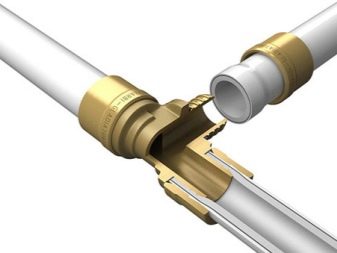

Fittings vary in mounting method. However, compounds can be accessed only in exceptional cases, because their use in the screed is a big risk. It is recommended to lay one piece of pipe and wind it onto the collector assembly. The service life of a corrugated pipe is 30 years (on average).

Which is better?

For heated floors, you can use any of the listed pipes, but the most popular and recommended are copper and metal-plastic options. Consumers choose them most often as they are durable, wear-resistant, and also have excellent thermal conductivity. Unfortunately, the cost of such pipes is high, but their performance fully justifies the price.

Making a choice in favor of expensive copper structures, it should be borne in mind that their installation is quite complicated. Because of this, you will have to spend extra on the services of specialists.

A good option are cross-linked polyethylene pipes, as they have excellent heat-conducting characteristics.

Least of all for a warm floor are suitable polypropylene pipes. As mentioned above, they are not flexible, so their installation can be a real problem. Also, heat-resistant polyethylene is not suitable for floor heating systems, as it can deform finishing materials in high-temperature conditions.

Specifications

The diameter of the pipe in the heating system plays a key role. From this indicator directly depends on what will be the speed of the coolant. Also, the diameter affects the selection of a suitable pump.

As a rule, in the warm floor there are tubes with a diameter of 12, 16, 20, 25, 32 mm. However, in most cases small specimens with a diameter of 16 or 20 mm are used.

Most often in the shops there are pipes for underfloor heating, the size of which is 20x2 mm, 20x3.4 mm, 20x4.2 mm.

Pipes also vary in bend radius. For example, in polypropylene versions, this indicator is 8-9 diameters, and in more flexible polyethylene pipes - 5 diameters.

As for the length of the pipe, it depends on the dimensions of the room.in which installation of a heat-insulated floor, and also power of the pump is planned. So, if the room has a simple rectangular shape, then the pipes can be placed in two available ways: to lengthen them or to reduce them.As a result, we can conclude that the installation of floor heating pipes largely depends on their size. During installation, these parts are poured with concrete (or another mixture), therefore, they are distinguished by strength characteristics and reliable tightness.

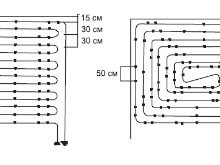

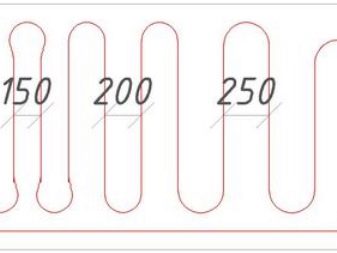

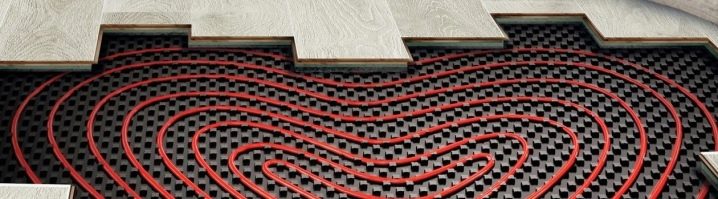

As for the pitch of the pipes, it is worth considering that it is also determined strictly individually. However, the most common are the steps from 10 to 40 cm. Of course, this indicator can be achieved only in case of sufficient plasticity of materials.

Most quality pipes for warm floors are characterized by high melting and burning temperatures. For example, popular specimens of polyethylene will melt only when the ambient temperature reaches 150 degrees, and the burning temperature of these products is 400 degrees Celsius.

Polypropylene pipes, which are poorly suited for laying in a floor heating system, are quite demanding to temperature conditions. They can be installed only if the temperature is kept at least 15 degrees indoors, and this indicator is not always typical for regions with unfavorable climate conditions.

As for expensive and durable copper structures, they are resistant to corrosion and can easily withstand almost any temperature conditions. This figure can vary from -100 to +250 degrees.

Metal products for warm systems can not boast such resistance to temperature extremes, as copper options. They withstand rates from -10 to +95 degrees. The limiting value is a mark of 110 degrees, and this temperature must be kept for a very short time, otherwise the pipe will begin to deform.

Payment

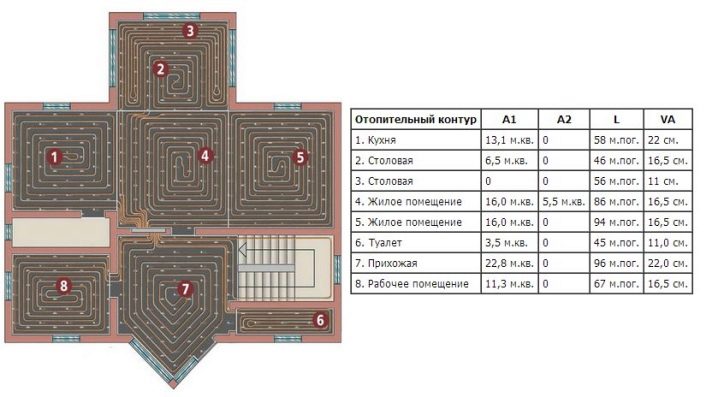

Do not rush to start installing floor heating pipes. First you need to make an accurate calculation of heat. Of course, complex computational operations are needed only in cases when it comes to large-sized areas. For an ordinary private house or city apartment, simple recommendations worked out over many years of practice would be enough.

First you need to resolve the issue regarding the diameter of the pipe. Most often for installation of a heat-insulated floor choose options in 16 or 20 mm. The diameter of the structure depends on many factors.

These include:

- Area of the room;

- The total number of living rooms;

- Working pressure in the heating system;

- The immediate temperature of the coolant;

- Pipe laying method;

- Boiler volume;

- Pump power (taken with a margin).

It is worth considering that the wider the pipe is, the more water will flow through it. Using such parts, the room will warm up much faster than with tubes of small diameter. However, wide elements will require a coupler of decent thickness and a more powerful pump, since it will require pumping a considerable amount of water, as well as maintaining the appropriate pressure in the system.

If you are going to install a warm floor throughout the house, then one pump is definitely not enough for you. In order not to face unnecessary problems, you should consult with experts who will tell you how to be specific in your situation.

The pipes themselves can be absolutely any (of all of the above), but the hydraulic resistance of the entire system will change slightly. Moreover, the pump power is usually selected with a margin, so the difference between different materials will not be significant.

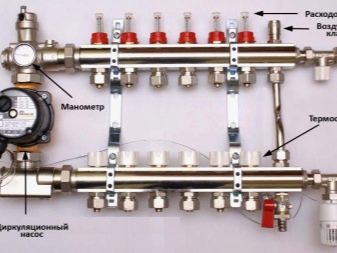

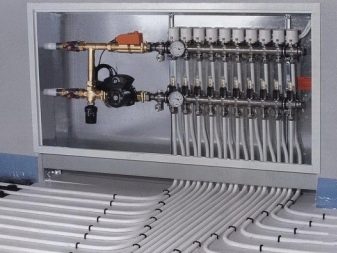

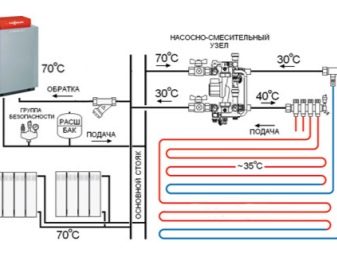

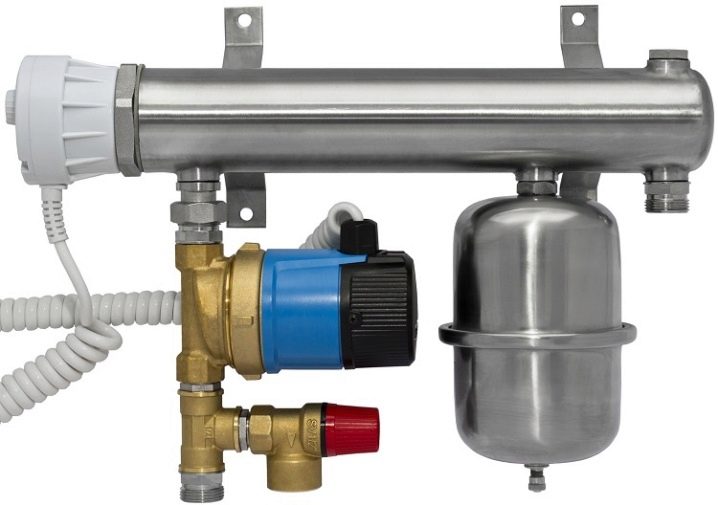

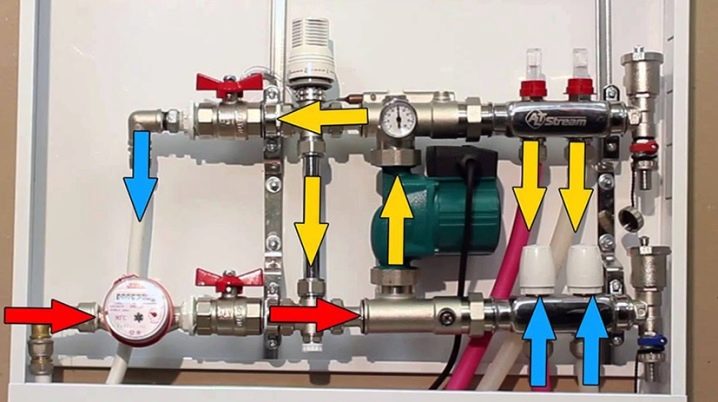

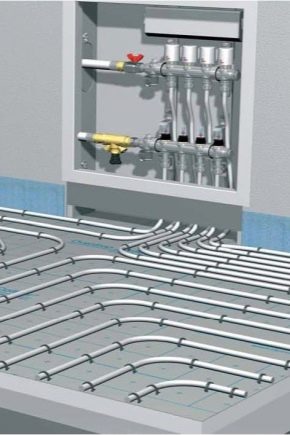

Calculate the flow of the pipe is recommended after making a separate place under the collector. This device is designed to maintain optimal pressure in the pipes, as well as for heating water in the system. Thanks to the collector can maintain a certain temperature in the room. Acquire this useful device is necessary, given the footage of the room.

The average size of the collector is usually 60 cm in length, 40 cm in height and 12 cm in depth. Such devices can be purchased at hardware stores.

The expense of a pipe of a heat-insulated floor in many respects depends on a loop step:

- 100 mm pitch - 10 p.m. (running meter) per 1 square meter;

- 150 mm - 6.7 base meters per 1 m2;

- 200 mm - 5 p. M per 1 square. m;

- 250 - 4 p. M per 1 m2;

- 300 - 3.4 p.m. per 1 m2.

It is also necessary to calculate the length of the contour of the water floor heating. This can be done on the basis of the diameter of the pipes and the material from which they are made. For example, metal-plastic constructions with a parameter of 16 inches should have contours that do not exceed the mark of 100 meters.

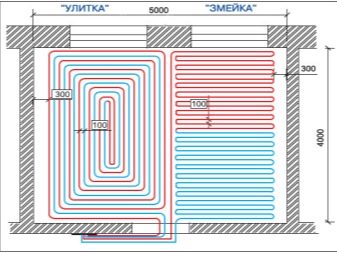

Also, in calculating the length of pipes, it is necessary to determine the layout of their installation. Most often, people choose the layout in the form of a snake or snail. For reliable pipes of cross-linked polyethylene, having a larger diameter of 18 mm, the maximum length of the branch should not exceed 120 m.

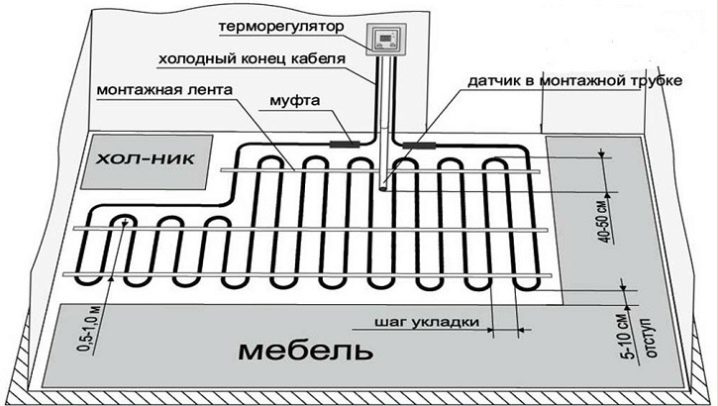

If you are going to put large and heavy furniture or equipment in the room, then under these objects you cannot carry out floor heating pipes. Because of this, the measured area will decrease. In addition, about 20 cm should be removed from the overlap. These nuances should be taken into account when calculating the floor space.

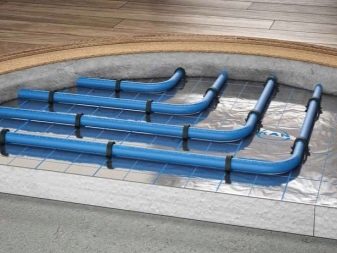

Piling

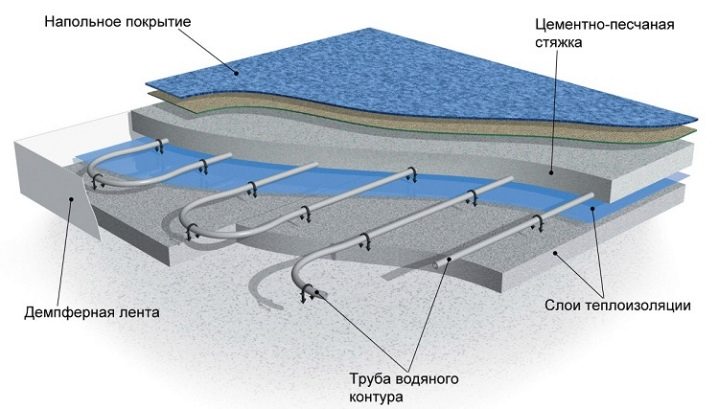

If you have made all the necessary measurements and stocked up with the necessary materials / tools, then you can proceed to the installation of the heating system. The first step will be the installation of thermal insulation.

Heat insulation installation

At this stage, preparatory work is underway. The floor is thoroughly cleaned of foreign objects, dust and dirt. After that, you need to decompose the insulating layer. To do this, often choose an inexpensive foam. It is necessary to lay its plates on the draft basis.

The thickness of one foam sheet should not be more than 12 cm. Calculate this parameter is necessary, based on the dimensions of the room and its location in the building.

Waterproofing installation

When you complete the styling foam (or other insulating material), you need to properly lay out the second layer of waterproofing.Most often for these purposes they buy plastic wrap. It should be attached to the walls in the room (next to the plinths) and supplemented with a reinforced mesh.

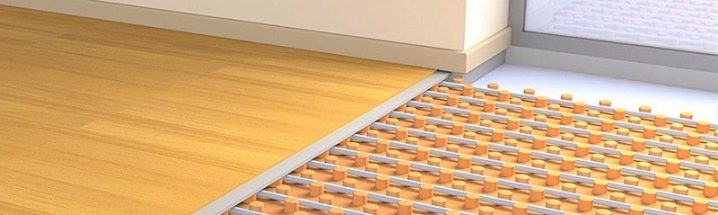

Pipe laying and fixing

After laying all the necessary layers on the draft basis, you can proceed to the installation and fixing of the pipes of the heating system. If all the calculations have been made correctly and you have selected a suitable scheme for the installation of the structure, then this work will not be difficult and will not take much time.

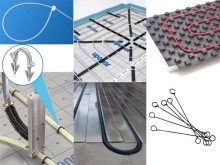

Laying pipes of a warm water floor, they need to be fixed by means of the special reinforced grid. To do this, use compounds in the form of stretch marks or clamps. After this stage, you can proceed to the crimping of the resulting structure.

Pressure testing must be carried out within 24 hours at working pressure. With this process, you can identify installation errors, as well as eliminate various mechanical damage to materials.

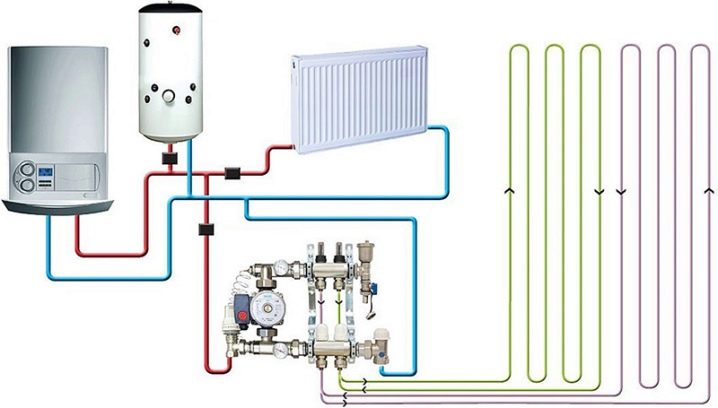

There are other ways to install floor heating pipes. For example, such systems can be connected to the main heating in the room. For the installation of such elements can be used as one-pipe and two-pipe line. They are installed not only in private houses, but also in ordinary apartments in the city high-rise building.The constant circulation of water in these constructions is ensured by the pump, which is responsible for the high-quality heating of the space and the return of the coolant through the return pipes.

As for the contour of such a heating system, it is quite possible to design it yourself. To do this, just take into account the location of the pipes in the room. If all installation work is carried out correctly, and the boiler will function properly, then this heating option will surpass conventional batteries in many ways.

Accessories

For high-quality installation of a heat-insulated floor the following accessories are required:

- Fixer for the stapler. This part is necessary for attaching the heating pipes with a stapler to the thermal insulation layer.

- Angle clamp.

- The fixing track for pipe laying. Most often, this item is made of PVC. It is advisable to buy tracks with integrated pipe clamps.

- Threaded fastening.

- Fitting.

- Special tile for laying pipes. Such parts are a panel made of polystyrene foil with pipe clamps installed.

- Mounting wire.

- Fastening plate with an additional adhesive layer.

- Expansion profile.

- Pump and mixing block.

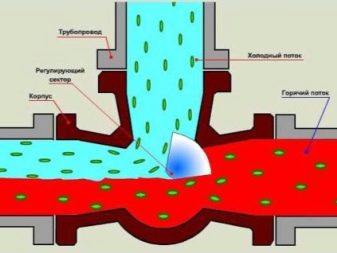

- Thermostatic mixing valve.

- Collector kit.

- Pump and mixing module.

- Tightening clamps.

- Foil for compensatory element.

- Double-sided tape for connecting panels.

- Heat insulation foil.

- Textured foil.

- Polyethylene film.

- Fixing anchors.

- Various fasteners (staples, wire, tracks, strips).

- Stubs

- Fittings.

- Reinforcement mesh.

- Hinges

- Damper tape.

- Substrate for a draft basis.

Possible problems

If you decide to independently make the selection and installation of pipes for underfloor heating, then you should know what problems you may encounter in this work:

- In order not to face the unpleasant problem associated with the formation of condensate, you should contact quality pipes. For example, options of metal-plastic are not confronted with such disadvantages, since they contain an insulating foil layer.

- Install the structure correctly. Mistakes made during installation most often lead to serious damage to heating systems.

- A common cause of damage to warm floors is damage to the pipeline.

If there has been a sharp drop in pressure, it is usually associated with leakage of structures. To such unpleasant consequences can lead to a hall of pipes or any other damage to them.

- Often households are faced with the problem of insufficient heating of the room while observing optimal pressure regimes. The most common cause of this defect is the uneven distribution of fluid through the branches of the pipeline. It is possible to get rid of this problem, if initially correctly adjust the work of the heated floor. For each circuit it is necessary to determine the ideal level.

- Often there are problems associated with electric floor heating equipment. Any sensors and pumps operating from the power supply may fail during their operation. You can make sure that such elements are in good condition by paying attention to the rotation of the rod during operation of the device - it should be visible. Also for testing equipment suitable multimeter. Thanks to this device, it is possible to check the power supply.

- Also common problems associated with underfloor heating are insufficient thermal insulation of the subfloor and weak boiler power.In order not to face the first problem, you should take a responsible approach to preparing the floor before installing the heating system. Do not save on thermal insulation, otherwise the room will not be as warm as you would like.

- The boiler is better to pick up with a small margin of power. In this case, you insure yourself against the inadequate functioning of the heating system.

- There are cases when the boiler has sufficient power, but coolness still prevails in the room. Perhaps this suggests that you need to properly clean the boiler and conduct an audit of temperature sensors or carry out a scheduled repair of the structure.

- Less often, the owners are faced with the problem of excessive heating of the living space. With such a defect in the room becomes unbearably hot, and the floor is very hot in a very short time. If this problem is not solved in time, the flooring may deteriorate, and with it the screed and the pipes themselves. Most often, excessive heating occurs due to improper setting of the heating system. In case you could not find out what the reason is, it is better to call in specialists before the base and finishing materials are subjected to deformations.

The listed problems can be avoided.In order not to encounter these defects, you should purchase high-quality and reliable materials that will last for a long time and will not cause any problems. To do this, refer to products from well-known manufacturers, who value their reputation and produce reliable components for floor heating.

You should also install the heating system in due form. None of the stages of the installation can not be neglected, otherwise the design will turn out to be low-functional and short-lived.

Expert advice

To find the perfect pipes for your warm floor and install them seamlessly, It is worthwhile to get acquainted with some recommendations of specialists, with the help of which many problems can be avoided:

- It is recommended to install pipes for underfloor heating in a company with an assistant. If you are going to make installation alone, then you should give preference to lightweight plastic types or corrugated pipe.

- Do not skimp on pipes for floor heating. Choose only quality products that will last for many years. As a rule, such products can easily withstand temperature drops and are not subjected to deformations such as fracture, which can lead to leaks.

- Choose only those pipes that have increased tightness, because a high-quality heating system must be protected from oxidation.

- If you want to achieve a better heating of the living space, then you should use pipes with a diameter of 20 mm. However, please note that for such structures will require the appropriate pump. By the way, it is always necessary to select it with a small margin of power.

- Pay attention to temperature conditions inside the system. The optimal rate of input and output should not differ by more than 5-10 degrees. As for the minimum temperature of the coolant, it should be no higher than 5 degrees.

- After drying on the screed floor warming cracks may appear - this is quite common. Such defects may appear due to the low density of the heat-insulating layer, poor compaction of the solution or excessive thickness of the screed. In order not to face this problem, you need to correctly lay out insulation boards, as well as properly dilute the solution for pouring the screed.

- Be careful with steel and metal structures in the floor heating system.Such parts are subject to corrosion.

Manufacturers and reviews

Qualitative and durable pipes for warm water floors are produced by many companies. Let's get acquainted with the most popular ones.

Valtec

Today, one of the most popular and sought-after is a large manufacturer Valtec, which produces high-quality metal-plastic pipes. Products of this brand is headed by many ratings. Pipes are multi-layered and very durable. The main advantage of Valtec pipes is their strength and ductility.

The material from which the pipes of this large brand are made boasts an enhanced resistance to mechanical damage. It also has excellent heat resistance. As for the degree of hydraulic resistance, it is quite low. The service life of Valtec products exceeds 50 years.

Most buyers were satisfied with the company's plastic pipes, but many were unpleasantly surprised by the high cost of Valtec products. Despite the relatively easy installation and flexible structure, such products often serve much less than the manufacturer claims, as many consumers say.

That is worth noting that the market is literally flooded with fake pipes, which are issued for Valtec branded products. These specimens are of poor quality and serve only a short time.

Rehau

The well-known company Rehau occupies a leading position in the market for the production of high-quality highways for warm floors. Products of this brand are made of cross-linked polyethylene and propylene.

Rehau branded pipes are resistant to temperature differences, high strength characteristics and long service life. If these products are subject to deformation, they very soon acquire the same shape, which indicates their plasticity. In addition, Rehau products are corrosion resistant, and this is especially important for water heating systems.

Consumers note the durability and reliability of the pipes of this manufacturer. I liked the people and quite simple installation, as well as the flexibility of the material. The disadvantages of products Rehau users consider too high prices.

Varmega

A large company Varmega is engaged in the release of engineering plumbing. All products of the brand are of unsurpassed quality. The range is represented by reliable and durable radiators,water supply and heating systems and other similar products.

Pipes of this brand have been appreciated by many buyers. They serve for a long time and during their operation do not fail, causing leakage. In addition, consumers are pleased with the wide range of Varmega, represented not only by heating systems, but also by various components to them.

Tece

The official dealer of Tece in Russia offers the choice of consumers a huge range of high-quality products. Heating pipes of this brand are in demand not only in the territory of the Russian Federation, but also in Europe.

Consumers were pleased with the manufacturer’s warranty for all Tece products. All ordered parts and assemblies are delivered as soon as possible. In addition, people say that the products of this company serve for a long time and seamlessly, and are also fairly easy to install.

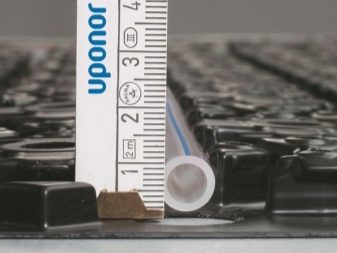

Uponor

High-quality insulated pipes produced by the famous brand Uponor.

Its range is presented:

- Heating systems;

- Cooling systems;

- Hot and cold water supply systems.

The company's products are characterized by a long service life, and are also ideal for major overhaul projects.Uponor heating systems meet all quality standards and are environmentally friendly.

Home masters and experts claim that the products of this company are of excellent quality and ease of installation. However, the cost of most pipes and heating systems Uponor leaves much to be desired, and some users have noticed that the installation of structures Rehau is easier and faster.

Stout

The range of this brand contains high-quality and reliable pipes made of cross-linked polyethylene, as well as elastic corrugated versions. In addition, the company offers customers accessories and components for various heating systems, manifolds and collector groups, boilers and fittings.

Most consumers have no complaints about the products of this brand. Moreover, many people prefer it instead of expensive Rehau constructions.

Frankische

This German manufacturer offers consumers a choice of high-quality pipes made of cross-linked polyethylene. Branded designs are able to withstand temperatures of +70 degrees and are highly wear resistant. In addition, Frankische pipes are not subject to mechanical damage and oxidation.

Consumers note the high quality of branded German pipes, as well as good thermal conductivity.The assortment of the brand has pipes of different cost, so you can choose the best option for any wallet.

Unidelta

Unidelta is a leading company in the production of high-quality Rex pipes made of cross-linked polyethylene. The range of this large brand has both floor and traditional heating systems.

The products of this company have long found their regular customers, who chose it for its excellent quality and excellent performance. Unidelta pipes are installed quite easily and quickly, which allows even inexperienced home craftsmen to work with them.

Many Russian brands also produce quality pipes for warm water floors:

- "RosTurPlast".

- ROSTERM.

- LLC “Sanext. About. "

- "Politex".

Russian manufacturers also manufacture fairly durable and reliable pipes made of polyethylene and metal-plastic. In the assortment of the listed companies one can find expensive and very affordable products. For example, the company Politex offers consumers PE-RT polyethylene pipes at a price of just 21 rubles per meter.

Successful examples and options

It was mentioned above that water floor heating pipes should not be placed under furniture or other heavy objects. Do not be afraid of this restriction.You can allocate a separate space for heating elements. For example, it may be the area opposite the soft corner in the living room, where there are no thumbs or coffee tables.

Quality pipes for underfloor heating can be installed in wooden houses. In such an environment, households will be much cozier and more comfortable. That is why the owners of private structures from a log house often address such heating systems.

Such constructions will be useful in city apartments. They can be installed in any room, from the hallway to the children's bedroom. The second option is the most preferred, because children love to mess around and play on the floor, so it will be better if it is warm.

Often, such modern heating systems are addressed in the design of loggias and balconies. Thanks to heating pipes and warm glazing, these rooms can be made residential and functional. Moreover, it is possible to install elastic pipes in them on the walls, thereby creating the most comfortable and cozy space.

In this video you will find an overview of pipes for a warm water floor.