Features of installing a water-heated floor with their own hands

Heated floors, heated by water - quite an attractive solution. But if you want to install them yourself, without resorting to the help of professionals and not spending money on their services, you will have to thoroughly study the topic and learn all the details. It is necessary to know both the principles of connection and the method of foundation device. Laying also have to perform a special technology.

Design

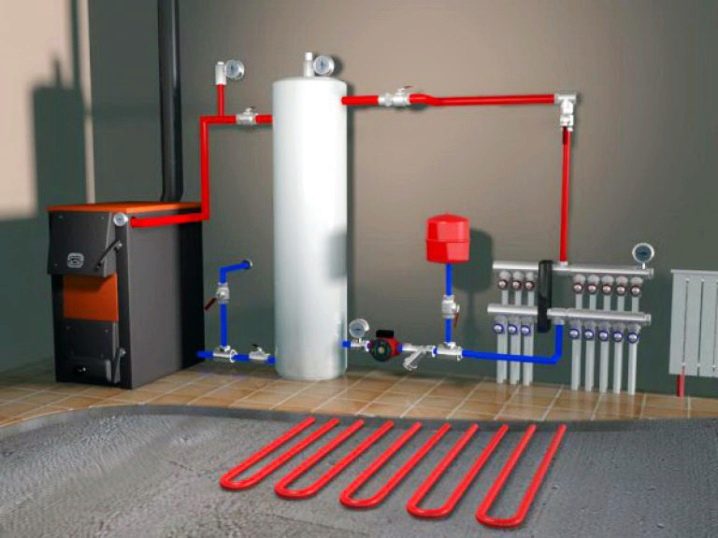

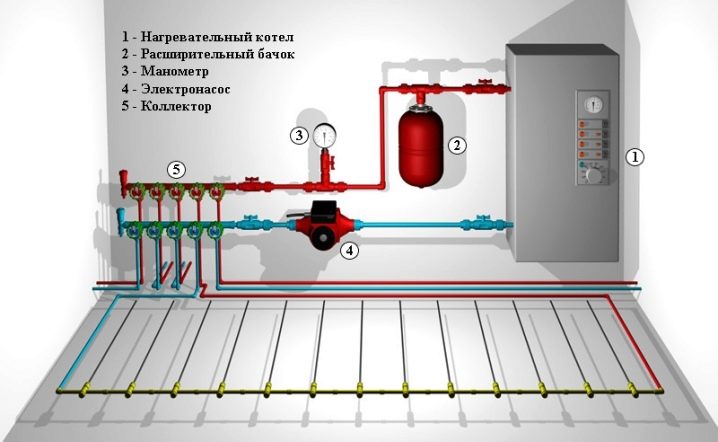

There are many varieties of warm water floor on the market. It produced dozens of leading manufacturers. But regardless of the specific brand and model mandatory components are:

- water heating boiler;

- water injection pump;

- ball valves (they are placed on the input to the boiler);

- pipes;

- collector device that allows you to customize and adjust the heating of the floors at your discretion;

- fittings, by means of which the main line is mounted, starting from the heater, and also the pipes are connected to the collectors.

Each of these constituent elements has its own characteristics. Thus, the pipes must be made of polypropylene with a reinforcing fiberglass layer, otherwise there is a great risk of their excessive expansion in the hot state. Polyethylene has a lower level of thermal expansion. The optimal diameter of the pipes is from 1.6 to 2 cm. Find out at the time of purchase whether they will withstand a pressure of 10 bar when pumping water heated to 95 degrees.

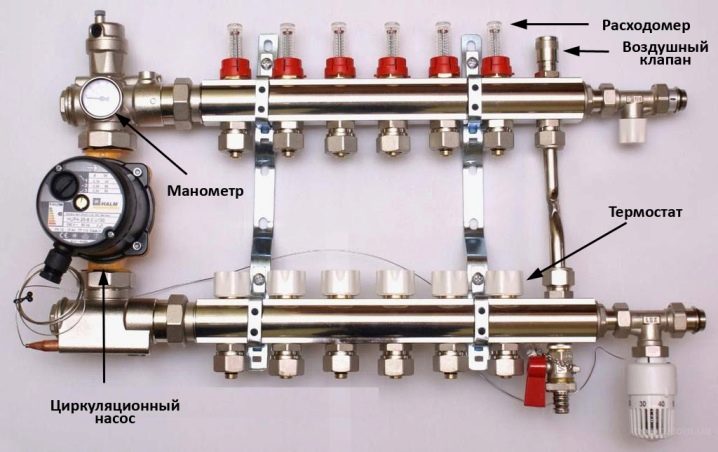

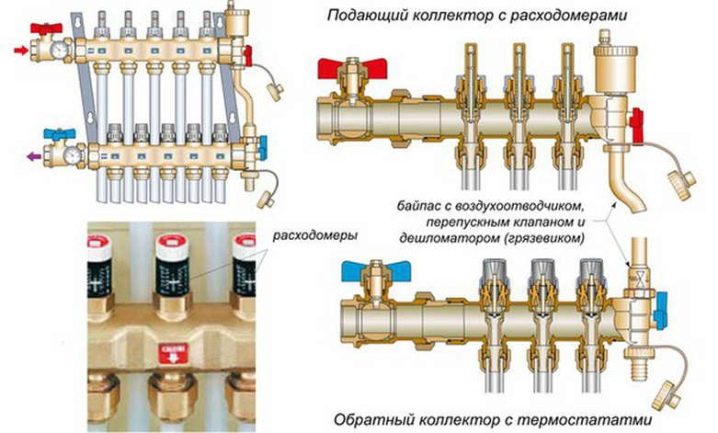

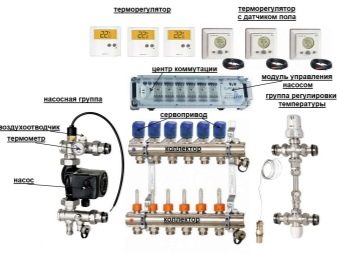

The collector, through which water enters the pipeline, is sometimes called a splitter. One of these devices sorts the hot water on the heating circuits, and the other - collects it after passing through the entire system. Both devices are placed inside the collector cabinet. High-quality execution of a collector group also includes:

- valves;

- air outlets;

- water control devices;

- units for the accelerated outflow of liquid in a critical situation.

A collector with a shut-off valve is impractical, so it is better to choose options equipped with adjusting systems that provide a smooth change in the flow of coolant into a particular circuit.

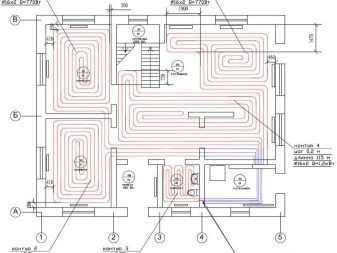

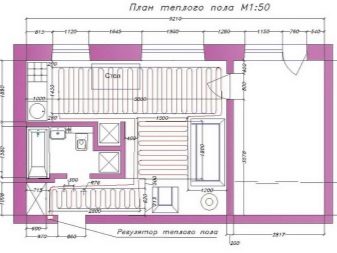

The exact length and installation step when installing the pipes is calculated individually for all rooms (rooms). There are no uniform standards here. If you do not feel sufficiently prepared for self-calculation using specialized software, use the services of design organizations. The designers will need to know what the size of the room is, how powerful the boiler will be installed, what the walls in the house (apartment) are made of, what are the properties of the ceilings and partitions. Be sure to take into account the type of floor covering, the device insulation layer and the diameter of the pipes.

The project should indicate not only the length of the pipe, but also the installation step and a rational installation path. Additionally calculate the heat loss, hydraulic resistance (it must be strictly the same in each circuit). It is undesirable to use large contours (100 m and longer).

It is better to divide each such into several smaller ones. All contours are strictly one pipe, therefore joints and couplings when laying in the coupler is prohibited. The verandas, the attic and the loggia are heated by a variant isolated from the adjoining rooms.

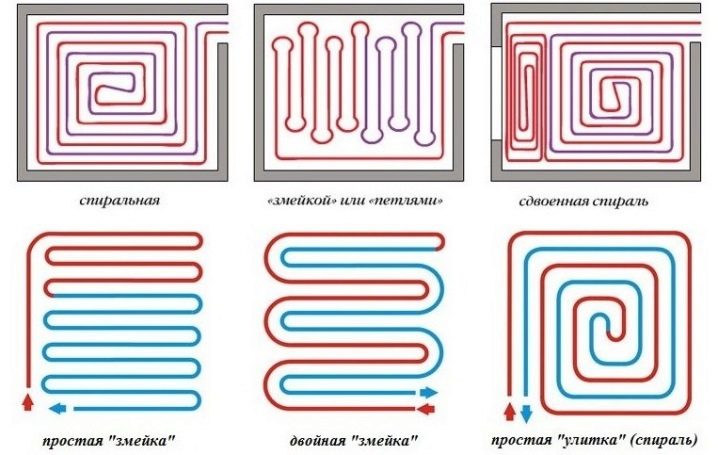

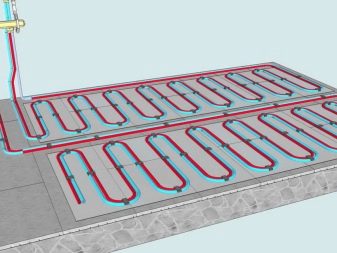

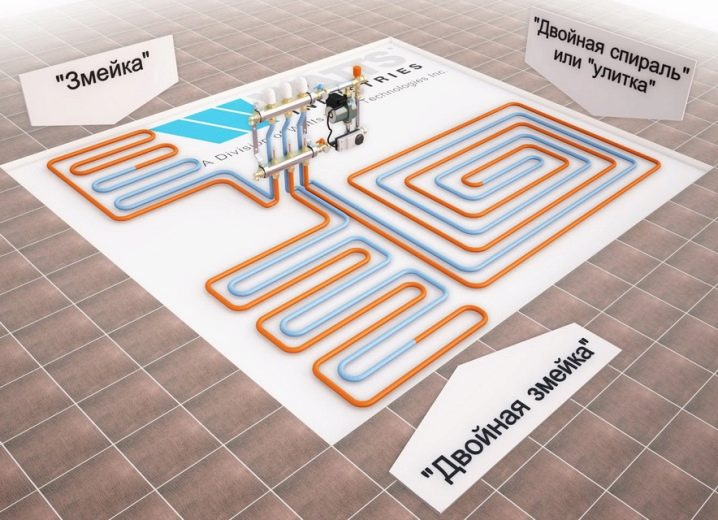

Remember that you need to lay the pipes, starting from the outer walls, and the uniform reduction of heating is achieved by the scheme "snake".

In rooms where there are only internal walls, the construction of a heated floor should be spiral, directed from the edges of the room to its middle. At the same time, a double step is maintained between any pair of turns.

For your information: collect and buy the collector should be only after how the number of contours and their characteristics will be calculated. The simplest solution, equipped with only one stop valve, is relatively cheap, but the lack of flexible adjustment will cause a lot of inconvenience. The other extreme to avoid is an expensive collector equipped with servo drives and pre-mixers.

Such equipment in a private house or apartment is completely superfluous, with the exception of giant cottages. When deciding which boiler to put, be guided, first of all, by its capacity, which, even when operating in peak design mode, should have a reserve of at least 15%.

To ensure the mixing of hot and cold coolant, thermostatic mixers are used.They are two-way (twin designs put on the supply and circulating pipes) and three-way (with the addition of an electric drive, mounted on the output of the boiler). Take care of the presence of a servo, thermostat: investments in these devices are justified by the fact that it will be more convenient to use the system. Servos are placed on the comb water supply.

Mechanical thermostats are relatively simple and reliable to use, so it is easy to use them even for people with little knowledge of technology. Electronic controllers are a bit more complicated, and if necessary, flexibly adjusting the parameters of the floor heating will have to be purchased by a programmable device.

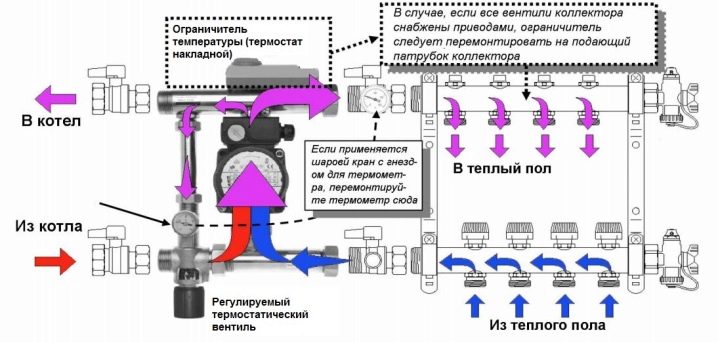

Having understood in general terms with the device and the configuration of the floor heating equipment, let's see now how it works. From the boiler (in rare cases from the heated towel rail) water enters the pipeline. Passing through a thermostatic valve, she gives him a known portion of heat. When a certain temperature is reached, the valve starts the process of mixing water taken from the return pipeline. For this purpose, a two-way or three-way valve is opened, installed up to the circulation pump (inside a special jumper).

The mixed liquid, passing through the circulation pump, touches the thermostat, which ultimately gives commands to open and close the coolant from the return circuit to the main one. Thanks to this scheme, the temperature of the water is maintained in a given range of values and is instantly corrected when it deviates from it. Then the water passes to the distribution comb (but only in a large room where there is a need to distribute the coolant over several circuits and then pump it in the opposite direction).

Mounting a warm floor in several rooms at once, place a temperature control manifold. This is necessary not only because each requires its own degree of heating, but also because the completely identical length of the circuit cannot be maintained. Adjustment is especially useful if one of the rooms is internal and the other has external walls.

Temperature controllers can measure the heating of the air in the room, or the temperature of the floor covering. Focus on what is important to you and do not confuse these two types.

Take care of the availability in the bypass heating system.It will allow to keep the equipment in perfect order, if suddenly the water supply to all circuits at the same time will be stopped.

Advantages and disadvantages

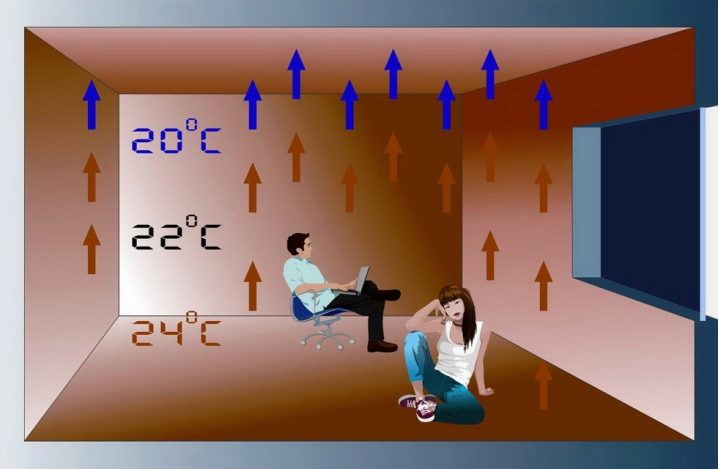

Water floor heating economical. A low coolant temperature (not exceeding 50 degrees) will reduce the current consumption of an electric boiler by 20% (compared to heating with radiators). Homogeneous heating of the entire area of the dwelling with a physiologically comfortable temperature distribution (22 degrees on the floor itself, 18 degrees at the face level) can also be considered a positive side. The hidden location of the heating system completely eliminates burns and mechanical injuries by direct contact with it and the coolant, which is especially important if there are children in the house.

Safe water floor also serves for a long time. Properly performed installation and the correct selection of components allows you to use the system 30-40 years. Unfortunately, there are drawbacks. For example, the increased complexity of installation (if you are not familiar with the problem or do not have the necessary experience, contact the professionals, or select the electrical version). If the installation is carried out with errors, this not only reduces the efficiency of heating, but also increases the risk of leakage.

If due to installation errors, normal wear or any other problem, the water begins to leak, you have to disassemble the floor, dismantle the heating structure, change it in whole or in part, and only then reconnect. Finally, in private homes it will not be possible to use water floors as the only sources of heat.

Long (tens of hours) warming up cannot be considered a disadvantage: all the more so because significant thermal inertia will allow the floor to consistently heat the air even during short-term interruptions. Be prepared that laying a water floor (even with your own hands) will be significantly more expensive than installing its electrical version. Some materials in terms of 1 square meter can cost at least 1500 rubles. When a team is involved, it will need to pay no less.

A good result is achieved on the condition that the floor is raised by at least 10 cm. Costs are also associated with the installation of adjustment systems, manifold cabinets and exhaust air valves.

Where is it used?

Such a heating system in the apartment room can only be used theoretically. Technical obstacles are very serious.The fact is that powering the pipeline with ready hot water is extremely dangerous and simply forbidden, and the special heating of cold water is expensive and difficult. In addition, any effective systems are voluminous and heavy, that is, they take a considerable part of the height of the room, putting a significant load on the floor surface and floors.

In a private wooden house, the heat loads on individual circuits, if they differ, are insignificant. Therefore, think carefully about whether to install expensive, complex automatic control systems in a small dwelling. A large cottage or a house where there are unheated rooms is another matter.

It is quite possible to put a water floor in a frame house, but its installation has an important difference - because of the lightweight foundation to the limit, it will be necessary to abandon the use of heavy screeds made of concrete or cement-sand mixtures. Correct to use dry polystyrene styling. She was specially invented for frame dwellings. Take into account that the thermal effect is maximum, you will have to think about good insulation of external walls, which are usually made thin.

The water floor heating system has its own specificity in the bathroom. If it is installed in an apartment, we recommend to receive consultation in the project organization, as well as form and register an official project and obtain consent from the neighbors. It is advisable to supply the circuit with coolant from the heated towel rail, and two-way valves at the inlet will not reduce the water temperature below and above the riser. Regardless of whether you want to heat the bathroom in an apartment or in a private house, Pay maximum attention to waterproofing. It is worth spending on a special kind of film or euroroofing material.

Filling of the base is done with the use of expanded clay or fine gravel. To exclude the appearance of irregularities, beacons are required. Take into account that it is not allowed to walk 5-6 days on covered bathroom coverings. At the same time, it is necessary to regularly wet the surface, otherwise it may crack. Since a cement builder will be able to make a cement mix on his own (which will not be covered with an intricate pattern of cracks in the next few years), it is better to purchase a fully prepared composition in the store. And to do experiments another time, while thinking about the design of a heated bathroom, for example.

Work Tools

In the process of installing underfloor heating, you need to use 18 different tools. Be sure to need:

- LBM;

- electric drill;

- screwdriver;

- construction hair dryer.

From the manual devices will be required:

- scissors;

- ordinary saw;

- metal saw;

- working knife;

- hammer;

- bit;

- vice;

- pliers;

- file.

Work with coatings is carried out with a spatula and paint brush. Measure the necessary dimensions need a tape measure and a meter ruler, but in addition to them, you will also need a sanding grid or sandpaper.

In addition to the toolkit, you will need materials:

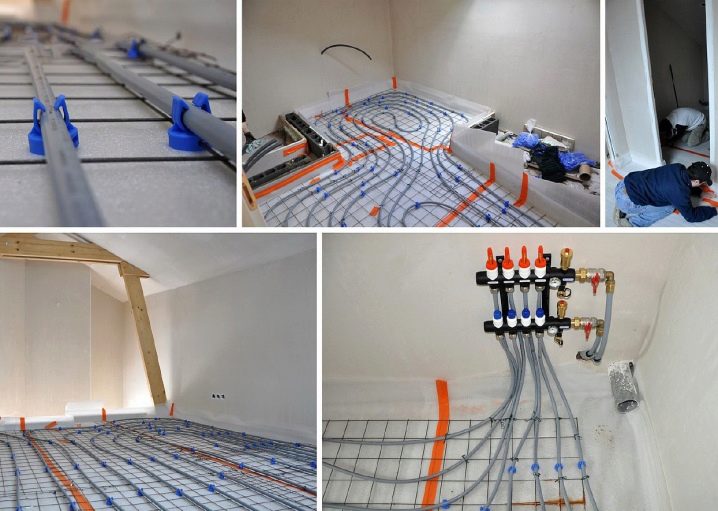

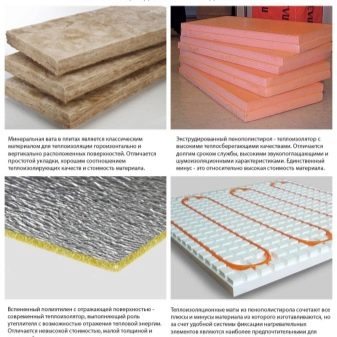

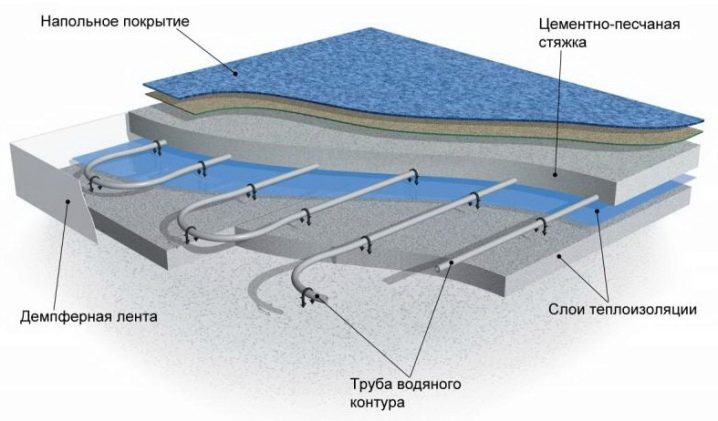

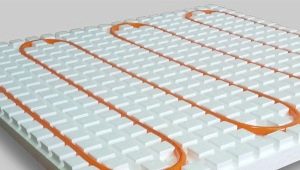

- Foil polystyrene mats or plates of the same material, processed by extrusion, are most often used for thermal insulation.

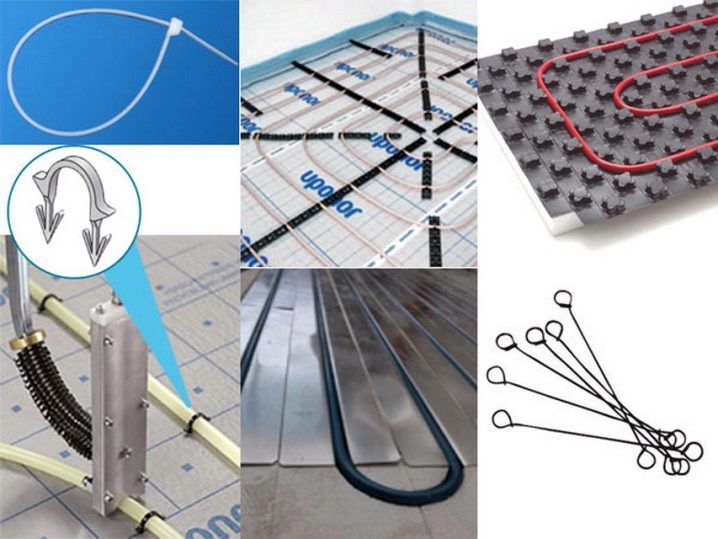

- self-adhesive damper tape should be from 0.5 to 1 cm thick. The pipes are fixed with brackets, mounting strips, turning arcs and some other details.

Foundation preparation

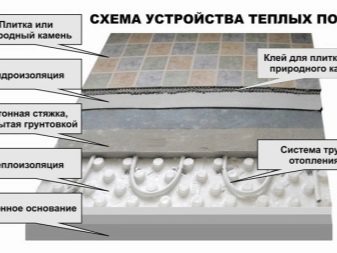

The previous technology must be completely removed to expose the underlying overlap.Immediately level the overlap surface, if the deviation from the horizontal exceeds 1 cm. If, after removing the old floor covering, cracks, chips and cracks remain, use a cement or gypsum leveling mix. Then, making sure that there is no dust, dirt or debris left on the surface, a layer of waterproofing is put on top of it.

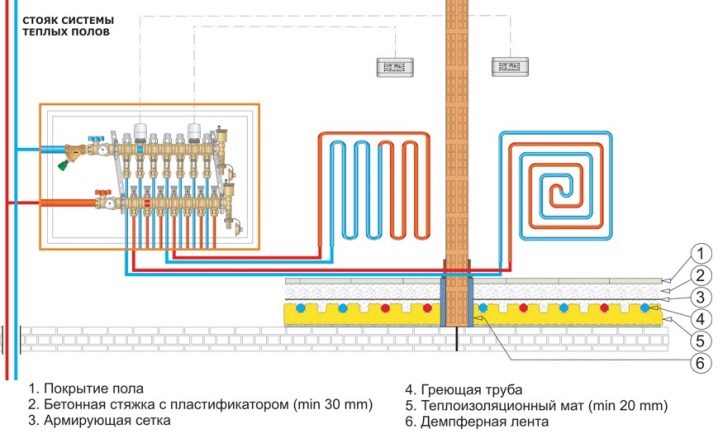

The perimeter of the base is occupied by a damper tape, which will help to compensate for the thermal expansion of the main flooring during heating. It is important to take into account, when there are several contours at once, the tape should be put in the gaps close to each other.

To reduce unproductive loss of heat, it is necessary to additionally warm the floor. Only in rare cases is it originally prepared in this sense. The choice of thermal insulation material is determined by such considerations:

- if the heated floor serves only as an assistant to the main heating system, you can limit yourself to polyethylene foam with a reflective foil layer;

- when the apartment is located above the heated parts of the building, it is required to use extruded polystyrene foam with a thickness of 2-5 cm, or no less durable substitutes;

- in the apartments, located above the cold basement, more serious protection is required - pour clay and put polystyrene foam with a common layer of 5 cm or more.

Modern manufacturers offer special warming materials for underfloor heating. One side of such heaters has channels for the installation of pipelines. It is recommended to use mineral wool, polystyrene foam and special mats. To reinforce the screed layer, a reinforced mesh structure is used, to which pipes can be attached. Their connection is provided with plastic ties, so there is no need for mounting strips and special clips. When the base is ready, it makes no sense to wait for something else - it's time to start installing the floor heating equipment itself.

Installation

Wiring diagram

Installation of a water heated floor always begins with the installation of a collector cabinet. Put it in such a way that the distance to the pipelines going to all rooms and from them was approximately equal. Hide ugly-looking closet can be built into the wall (load-bearing walls are not suitable for this). Consider that the box is placed above the warm floor,otherwise, the air exhaust will be blocked.

In the modern sample system (with rare exceptions) circulation is provided by pumping equipment. Togo pump, which is installed inside the boiler, is enough to pump water over an area of 150 sq m, even if the building is two-storied. If the total area of the building is larger, you will definitely need to install additional pumps with advanced functions.

In order to be able to maintain the heating system without draining the water, the inlet and outlet of the boiler are equipped with shut-off valves. Using them, you can disconnect the heater for repair and maintenance at any convenient time. If there are two or more collector cabinets, the main supply route is equipped with a splitter, immediately followed by narrowing adapters.

Attaching pipes to a manifold implies the use of compression fittings, or eurocone devices. If there is a need, you can carry out such pipes through the walls, close them on all sides with a warming layer of foamed polyethylene. When all parts are laid, and each unit is connected to its proper place, the system must be tested. By supplying water to the pipes, they are kept under pressure of 5 or 6 bar for 24 hours (depending on the design working value). If such a check did not lead to the appearance of visually noticeable extensions, you can safely proceed to pouring the concrete layer.

It is allowed to fill in the screed only when the fluid is supplied under the planned pressure. Drying time to readiness is at least 4 weeks (in ideal conditions). If a tile is laid on top, the screed must be 30–50 mm thick, and the pipes are spaced 100–150 mm apart. Failure to follow these rules, even if the connection of all elements is normal, will lead to uneven heating of different parts of the surface.

Under the laminate or linoleum screed may be thinner. Then the reinforcing mesh helps to compensate for the decrease in its strength. If the warm floor is placed under the laminate, it is not necessary to equip the insulation, otherwise the energy efficiency of the heating will be reduced.

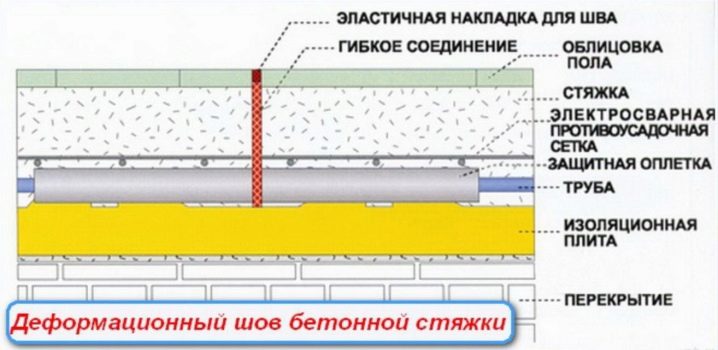

Shrink seams are fitted in the screed is necessary if:

- the area of the room exceeds 30 sq m;

- there is at least one wall longer than 8 m;

- length is less than 50 or more than 200% of the width of the room;

- The configuration is complicated and fancy.

For the design of screeds, it is allowed to use cement-sand mixture on the basis of Portland cement (at least M-400, and even better to use M-500). When ready concrete is used, its grade should be M-350 and higher. In addition to laying the damper tape, the reinforcing mesh where the seam passes is divided. The thickness of each seam is 1 cm, and its upper portion is treated with a sealant. With the passage in these places pipes They should be placed only in the outer corrugated tube.

The launch of water floors in the work should occur at the onset of the first cold weather. Consider that the thermal inertia of the flooring is great, and only after a few days, when it is overcome, optimum conditions will be created.

To the battery (as well as to the existing system of central heating and hot water supply) you cannot connect a heated floor! This will not only cause the sanctions of the controlling state bodies, but also lead to the disruption of the normal operation of the utility systems. Be sure to put an autonomous heating boilerwhich will be the source of hot water in the system. In addition to manual adjustment, you can control the warm floor through a servo and sensor, or weather automation.

Since the system must have control and regulatory components, it must be connected to electricity. Warm floors in different rooms can be controlled by one thermostat only under the condition that the thermal conductivity of the floor covering coincides completely. Such a scheme requires the same or slightly different length of the contours. Thermostats can be connected to the mains directly or through an RCD, which is much safer.

For laying the power cables, either a wall in the wall or an additionally protecting corrugation is used.

Please note that at the time of the primary connection machines must be set to the "off" position. Carefully see which wire to which phase should be connected. An alternative installation scheme (without a concrete screed) will be disassembled a little further. For the time being we can only say that its main variants are placing pipes into polystyrene foam grooves, or into grooves made of wood. It is time to see how the water floor heating pipes will be laid.

Laying technology

Modern technology for installing underfloor heating means laying pipes with retaining them with special fastening profiles. The profiles themselves are attached to the base with dowels or screws.The advantage of this solution is that the profile in the production is supplied with clamps. You do not need to carefully measure the step from one turn to another and carry out its careful calculation. A simpler option - fasteners on plastic ties, pressed against the reinforcing structure.

However, the simplicity of such a scheme requires the elimination of unnecessary force when tightening. Make sure the loop is free. The coil of pipe is carefully unwound, and not immediately, but directly in the process. The manufacturer's instructions always dictate that the bend be carefully b at the smallest possible radius. When using constructions made of polyethylene, it is usually 5 pipe diameters. Do not pinch the product if a whitish band appears on it., as this means the appearance of a crease, which subsequently easily breaks through and will lead to flooding.

The installation according to the “snail” or “spiral” scheme is recommended for large rooms, and makes the heating more even. The classic "snake" is best manifested in small rooms, and if you want to apply heat to the flooring in a medium-sized room, it is advisable to prefer a "double snake" in which the hot and return pipes are parallel.

Whatever methods are chosen, try to reduce the number of joints between the pipes, as well as the number of turns. Such sites, despite all the perfection of modern technology and careful execution by professionals, dramatically increase the threat of leakage. Ideally, connections should be made only at the entrance to the boiler and at the conclusion of it.

Docking on bends and turns is categorically unacceptable. When fixing the laid pipes to the screed, place the retaining elements on each meter.

For the connection of pipes, in addition to the above options, there are still such devices:

- polyamide pull collar (2 pieces per meter);

- steel wire (similar consumption);

- stapler and 2 fixers per meter;

- fixing tracks, or strips based on PVC;

- polystyrene mats;

- aluminum distribution plates.

The rules of work indicate that regardless of the method of holding the pipes, their fixation is ensured by grids with a square cell of 15x15 mm, wire diameter maximum 0.5 cm. Having introduced modern automatic devices into the system, you can control the flow of water through the pipes human factor, but also remote.

The final choice of installation options should occur taking into account the private properties of the premises and the functionality of their individual parts. The "snake" system is designed to supply water initially to a cold area, and only then throughout the rest of the floor, for example.

When the screed under the laminate or linoleum is made thinner than conventional indicators, an additional reinforcing mesh is placed directly under it above the contour of the heating pipes.

How to do without a concrete screed?

A long wait (about a month or even more if weather conditions are unfavorable) does not suit everyone. Instead of a concrete screed, you can use a floor covering. When you lay the pipes, you will need to form a backing for the finishing floor. If there is laminate upstairs, use cardboard and polyethylene foam. Filling under the tile is also not required. Under it, as well as under linoleum, they are preparing a special design based on cement-bonded particle boards.

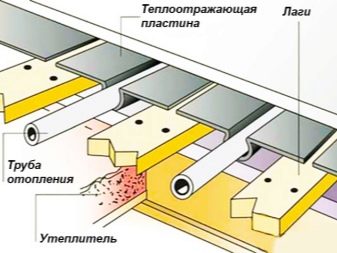

Warm water floor on the coating of wood is mounted using the distribution plates of aluminum. Pre-prepare the boards in which the necessary grooves are formed.Do your own hands as much as possible the smooth surface in the bathroom, if you lay wood chipboard, plywood or gypsum-fiber sheets over the pipes. Always check carefully whether these materials comply with health regulations.

It is possible to connect a warm water floor without a screed by laying pipes between the lags and on the surface of the subfloor. Modular variation (wooden blocks with milled grooves) can be replaced with a rack, in which the plywood sheet is covered with slats. The intervals between them are used for the installation of pipes. Laying between the lags necessarily requires the use of waterproofing, insulation, reflective plates with holes for the passage of pipes, the pipes themselves, a sheet of plywood and the final coating.

Imposing on the flooring also implies the placement of insulation in the breaks of the lag on top of waterproofing, and plywood or draft boards are placed above. Nuance: grind boards to make channels for laying pipes. The reflective layer is made of foil attached to the boards using staples. The pipes in the channels are held by narrow metal plates placed on top, the plates themselves are also attached to the boards.

Instead of boards, you can use mats of polystyrene of standard dimensions 1x0.5 m, attached to each other by fastening the “lock” format.

Always (regardless of the method of laying the floor with heating) keep the interval to the wall 0.1 m, as it will allow to substantially reduce the effect of thermal expansion of the floor materials. A hydrophobic coating is placed over the decking or lags. Only after this comes the turn of the formation of the fair floor.

In addition to the two described options for forming a heated floor without a screed, it is allowed to use a foam or wood substrate, chipboard. Light, relatively thin floors are more expensive and not too durable, but they are recommended to use:

- if necessary, lay new over the old coating without dismantling;

- if the height of the dwelling is limited;

- if installation speed is critical to you;

- if it is impossible to properly deliver the concrete;

- if the floor overlap is wooden;

- if the structure is high and the load cannot be exceeded.

In addition to facilitating the construction, the underfloor heating system has one more indisputable advantage - it is easier to repair.Even the best pipes, laid correctly and operated carefully, can suddenly burst. If you want to still use a full-fledged screed, but do not wait for 28 days of complete drying, you should apply semi-dry mixture. Special additives in them can reduce the required amount of water, but the cost of such building materials is higher than in a simpler version.

Keep in mind that the installation of warm floors without a screed is permissible only if the floor level drops are 0.2 cm for every 2 square meters of surface. If it is a less even, tightening layer, even the thinnest, it is still necessary to create it.

Possible mistakes

Even experienced home craftsmen, who for the first time take on installing a heated floor, can make serious mistakes. Often dried concrete screed covered with a grid of cracks. The causes of this defect are varied. You can avoid its appearance if:

- take care of the optimal density of insulation;

- make high-quality shrink seams;

- do not overestimate the recommended thickness of the screed;

- Do not attempt to dry it excessively quickly, speed up the normal process of solidification;

- thoroughly seal the solution and strictly maintain the proportions during its formation;

- add plasticizers according to the recipe.

The minimum density of insulation is 35 kg per cubic meter. Preventing excessively rapid drying of concrete will help cover it with a film of polyethylene.

Eliminating installation errors by 95% (except those caused by inattention, haste and manufacturing defects) will help drawing up draft designs. Having thought up the implementation of the system, “seeing” it on a piece of paper, you can detect shortcomings in advance and avoid their manifestation. It is better to mark on the sketch the furniture placement areas and other places where for some reason or another the circuit with the coolant should not pass.

The entire area that must be warmed is divided into plots of 15 sq m each. At any site, the pipeline installation step is 10 cm. A common mistake is that people do not think on time, which wall is better to install a collector, or to overly bring it closer to one heating circuit, distancing from others. Properly select the heat source that connects to the floor heating.

Comfortable life is provided at temperature of the heat carrier from 40 to 45 degreeswhich allows to warm up a floor to 26-30 degrees. Such heating is provided by condensing boilers, while other heating devices are not capable of heating water less than 60 degrees.

Never lay a heat-insulating layer over a warm floor and do not use carpets indoors., because these solutions will only worsen the quality of heating. Remember that polystyrene insulation is dense, and it is not able to correct the roughness of the roughing screed, so from the first steps you need to do everything as accurately as possible. Regarding the thickness of polystyrene, contrary to the recommendations of most manufacturers, it is not required to withstand 10 cm (as a rule, even on the ground floors, 8 cm is enough).

Above the layer of insulation should not just lay a reflective film (this is a mistake), but it should be laid out exactly and wound up for polystyrene at the edges. The bottom material itself should be pressed tightly to the walls through a damper tape. Do not tape the parts together, as they are intended for very different purposes. It may be harmful to health.

Correctly smear the edges of the blocks with glue. Another blunder often encountered in the work of non-professionals and “shabashniki” is the different indentation of pipes from the walls. Real masters make it at least 100 mm and uniform in all rooms.

If it is necessary not only to put the pipes, but also to organize the rotation of the pipeline, it is necessary to bend the metal-plastic structure manually (and not with the help of springs or other ancillary tools). Note that the reinforcing mesh should not touch the surface of the pipes, as this is considered a gross error. The contours subjected to thermal contraction and expansion will continually push the network, and it will soon be deformed and out of order.

Professional Tips

According to experts, in the coldest parts of the room it is necessary to compact the laying step of the “snake” to 0.1 m. First of all, this is done by laying a warm floor near the external walls. Do not attempt to heat more than 40 square meters of floor with one circuit. It is also worth organizing separate circuits for neighboring rooms with different temperature conditions. Installation of metal-plastic pipes under the coupler is preferable to the installation of the pipeline from other materials. The temperature of the coolant should increase steadily with the output to the level you require. 70-72 hours after connection.

The best installation point for the pump is the return pipe located directly in front of the boiler.Most often, expansion tanks are mounted in the highest section of the circuit, however membrane closed systems can be performed in any other way. If you are powering the gas boiler from the main pipeline, and not from cylinders, you should get the approval of the local authorities. Only specially trained personnel working in licensed organizations should be involved in the work.

Hinges from a single pipe with a cross section of 1.6, 1.7 or 2 cm are distinguished by a minimal risk of leakage at the joints.

The average floor temperature of residential premises is 26 degrees according to current standards, and in those places where people are periodically, and a special thermal regime is required, it is 31 degrees. The highest permissible difference of heating of individual parts of the floor and coatings in different rooms is 10 degrees.

In order for the thermal return to be optimal and not to force the system to work excessively, the floor must be carefully leveled.

Deviations from the plane of more than 5 mm are not allowed.. Their presence leads to overflow of contours with air and unstable, inefficient operation of the heating. The functions of steam and waterproofing often performs plastic filmand its minimum thickness is 0.02 cm, otherwise it will not be possible to guarantee full protection of the insulation from moisture.

Laying the film should be overlapped to 100 mm, and its borders are held by adhesive tape, which cover the intersection of the floor and walls. When all the lower layers have been laid and even the pipes themselves have been installed, it is necessary to press them differently depending on the material. Thus, metal-plastic structures must be subjected to an internal pressure of 6 bar for 24 hours. Before this, the circuits are filled with 100% water, until the end of the release of air through the taps to drain.

There is another option: the heat carrier inlet, bring its temperature to 80 degrees, maintain it for 30 minutes, after which, keeping the pressing pressure, put the concrete screed.

If the pipeline is made of cross-linked polyethylene, reducing the pressure, you will need to add water, and then after 30 minutes repeat the check. Then they wait 90 minutes, restore the previous pressure and leave the heating circuits alone for 24 hours. By the end of this pause, the pressure drop should be a maximum of 1.5 bar.

After installation and verification of all parts of the pipeline and additional components, take a picture of their location and make a description with reference to landmarks.Subsequently, if you need to do the repair of a heated floor, such information will greatly simplify and speed up the work.

When you need to heat a very small area (the area around the sofa, armchair, table and other furniture, for example), flexible rolls with integrated plastic tubes are preferable. The technology allows cutting off the necessary part of the roll, its bending at any angle is the main thing that the channels for the passage of fluid remain intact.

Observance of these moments will allow to achieve full success in the installation of a heated floor and enjoy its stable work for several decades.

To learn how to make a water-heated floor with your own hands, see the next video.