Choosing a pump for underfloor heating: details and features

Heat in the house is a necessity that every person needs. For space heating there are a large number of methods and devices. One of them is rightfully recognized as a floor heating system. It is widely used in residential and social facilities. There is no particular difficulty in organizing a warm floor, because many people take it upon themselves to implement this idea without attracting specialists. Today we will deal with the choice of the pump, which is considered a mandatory component of a warm floor.

Special features

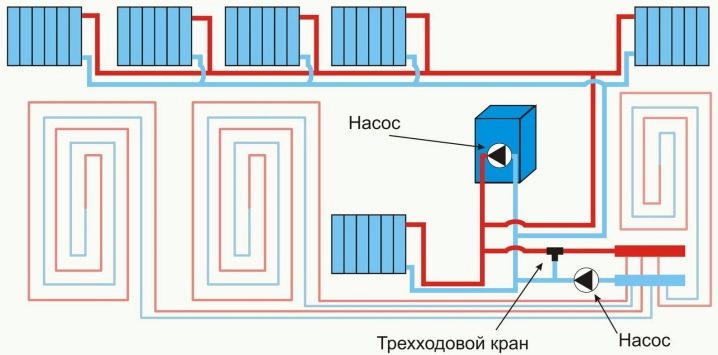

The design of water floor heating consists of a large number of pipes, which in many places have bends. Water cannot move independently through such a system, therefore installation of a centrifugal pump is necessary, which will ensure the circulation of the coolant.Water loses its thermal energy, which leads to a change in pressure inside the system. Pump circulation type belongs to the group of centrifugal devices. Its functioning depends on the electric motor and the shaft equipped with the impeller.

For the manufacture of the case using different materials: stainless steel, cast iron, various kinds of polymers. Airtightness is not typical for a warm floor: air will accumulate inside the system during operation.

This state of affairs is associated with oxidation processes, in front of which the cast iron does not have high resistance. Therefore, it is better not to choose such pumps.

To connect to the heating system, the pump casing has a pair of pipes. An additional feature is the air vent, which allows you to remove air from the system. In its absence, the user will have to independently unscrew the nut on the body, thus releasing the accumulated air in the system. To choose a pump that will exactly meet your requirements, you need to understand this topic well. All this can be found below.

What is it needed for?

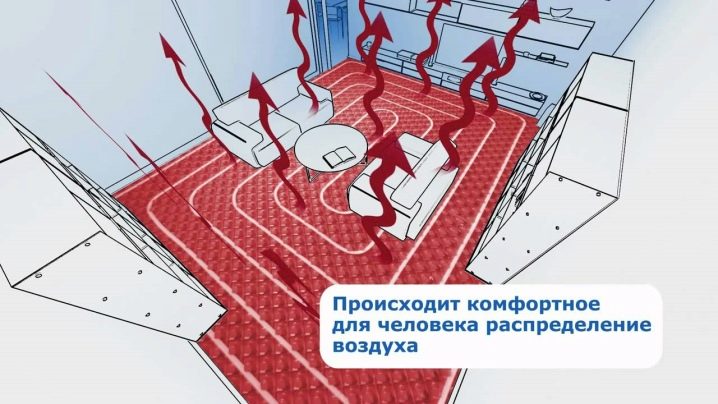

Underfloor heating system consists of narrow pipeswhich in the process of laying often and strongly bent. Such a complex design does not allow the coolant to circulate freely. This is also worth adding the maximum temperature of the coolant, which should not exceed 40 degrees. Under these conditions, to achieve high efficiency and system performance is problematic.

Any failure in the work adversely affects the state of the water circuit and causes the formation of air congestion. To avoid such problems, be sure to install a pump. This mechanism is responsible for the following important points:

- creating the right pressure and maintaining it at the right level;

- water circulation;

- smooth operation;

- effective heat transfer;

- lack of air traffic jams;

- prevention of problems.

All this will be possible with the right choice of a pump that will exactly match the system parameters and user requirements. In rare cases, a floor heating system can function normally without a pump. Such situations occur, although rarely:

- work from central heating;

- connection of the system with hot water supply (in apartments is often chosentowel warmer for this purpose);

- the presence in the gas boiler the possibility of connecting several water circuits simultaneously.

Kinds

All circulation pumps that are released for underfloor heating are similar to each other. Of course, each manufacturer wants to create a unique product, but no one has yet succeeded in making a breakthrough in this area. The general classification is applied to all models, having studied which, it will be easier to choose a circulation pump.

Wet rotor

This type of device - mini motors. Their size is reduced due to the proximity of the impeller to the rotor. In some models, these two elements are located in the same housing. To prevent water from entering the engine, manufacturers have a reliable oil seal on the drive shaft. It is made of extremely durable rubber, which has a high resistance to external factors.

Some models have a double hydroprotection. Due to the fact that the motor is small, it can be installed in a heated room. It runs silently, has low power consumption, is characterized by low weight.

Dry

Devices with a dry rotor have a separate housing for work items.They have a lot of power, so they are chosen for large spaces.

To install these pumps, you need a separate technological room (most often it is a boiler room). Installation is carried out on a separate frame.

The weight of these devices is impressive, the work is accompanied by noise, it is advisable to use them for large areas, so they are rarely chosen for private buildings. For dry-rotor pumps, an additional protection kit is provided for the electrical components.

Industrial

For such objects produce the same pumps. Their mounting is carried out by connecting flanges with a diameter of more than 50 mm. Such pumps possess twin constructionthat is convenient for high temperatures and increased load on the system. At the right moment, the second pump is activated, as a result, the efficiency increases, the coolant circulates more actively through the system. If one motor fails, the second one can be turned on.

Models are divided by the number of speeds. Single speed versions are designed to work with a single temperature regime. Multi-speed ones are designed to work in any thermal temperature system (for heating various objects).

For uniform heat transfer it is necessary to ensure stable speed of the coolant.

How to choose?

In order not to be mistaken with the choice, it is necessary to study the advice of professionals, which we have selected for you:

- Purchase of a pump must be made simultaneously with all structural elements of the future system. So it will be possible to achieve maximum system efficiency and ensure its durability. Repair work will be expensive, so it is better to protect yourself immediately.

- Pump selection should be based on unit capacity. This parameter can show performance in liters or cubic meters. It all depends on the amount of coolant that will be in the system. Multiply this value by 3 and get the required pump performance.

- The pressure should be selected in accordance with the parameters of the pipes that make up the system (taking into account the diameter, length, material).

- A small pump is easier to place in the room, but the dimensions of the unit are directly related to its capacity. Small pump - limited power.

- Phase also affects pump selection. Usually for private objects choose single-phase units.But industrial areas require the installation of pumps with a three-phase motor.

- Foreign pumps are not always better than domestic counterparts. The products of our manufacturers are designed for low water quality and the characteristics of use characteristic of our area.

How to calculate power?

It is impossible to equip the system with the first pump fan and connect it to the collector. Its parameters must clearly comply with the requirements of the system. To do this, make calculations that allow you to determine the necessary indicators of power and pressure of the unit.

To determine the power it is necessary to use the formula Q = 0.86 × Ph / (t sp. T - t rev. T), where:

- Q - coolant flow rate per hour, measured in cubic meters;

- Ph is the maximum power indicator on the circuit, measured in kW;

- tpr. t - level of coolant temperature at the flow;

- t t is the level of the temperature of the coolant at the outlet.

In the presence of several contours, it is necessary to calculate the total indicator in which each is taken into account. In the formula there is a temperature difference of the coolant at the inlet and outlet. This indicator is formed depending on the following indicators:

- The length of the system directly affects the temperature difference. With increasing contour increases the area intended for heating. This leads to an increase in the consumption of thermal energy and a significant temperature difference.

- Thermal insulation of the flooring should be organized at a high level, in particular for rooms on the ground floors. If the insulation technology was violated, the energy will be spent on heating the soil, and not the room. In this case, the heat loss will be enormous. This factor is displayed on the pump operation.

- The climatic location also affects the temperature difference and the required power of the equipment. For the northern regions need a higher power reserve. For the southern regions you can save a little on this indicator.

Not only in power you need to choose a pump. The calculation of the water velocity should also be made. This indicator should overcome the hydraulic resistance, which is created by water inside the system. The magnitude of hydroresistance is influenced by a number of factors:

- contour length;

- pipe section indicator;

- water circulation rate.

Control system and progress

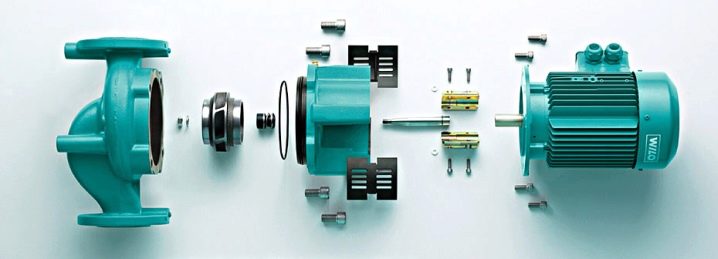

The basis of the pump is the body and the motor (rotor). It is bolted to the inner surface of the case. The impeller is located on the motor shaft. This information is enough for a regular user, no need to know more.

The operation of the pump inside the system is extremely simple. The water gets inside the case, it is seized by the impeller and with a force is thrown in the opposite direction. Many pumps feature speed control. In this case, you can achieve optimization of the workflow, which will allow economical use of heat.

The process of controlling the operation of the pump can be carried out in several ways:

- The mechanical control method requires the user to control the situation and periodically interfere with the operation of the pump. For this purpose, a special mechanism is provided on the body. Such units are available, but not very convenient to use, although you can put up with such inconveniences.

- Electronic control automates the process of selecting and setting the desired speed. For such units will have to overpay a little, but the process of operation will not require intervention.

Manufacturers

To make the best choice and put the right pump into the system, which will be suitable in all respects, it is necessary to focus on the manufacturers represented on the Russian market. We selected the most reliable, which are worthy of attention:

- Grundfos - trademark from Denmark, well known in the field of units for heating systems.

- Wilo - a company from Germany, which produces high-quality and reliable equipment. The cost of these units is appropriate.

- DAB Pumps produced in Poland. They are more affordable than the aggregates described above. Their quality and durability at the proper level. DAB pumps are a worthy option for a limited budget.

- Sprut - A Chinese company that supplies affordable pumps to the Russian market. The quality is satisfactory, with proper care and gentle operation can last a long time.

Good examples

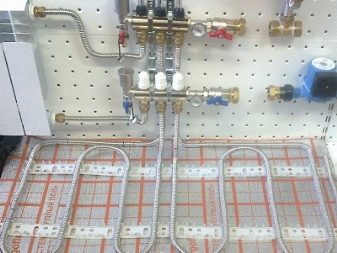

A great example of how a system should be designed for underfloor heating. The pump is positioned correctly, which is essential for its long and trouble-free operation. The system has a separate enclosure designedthat will hide all the elements and save the design of the room.

You can find out how to choose a circulation pump for underfloor heating in the next video.